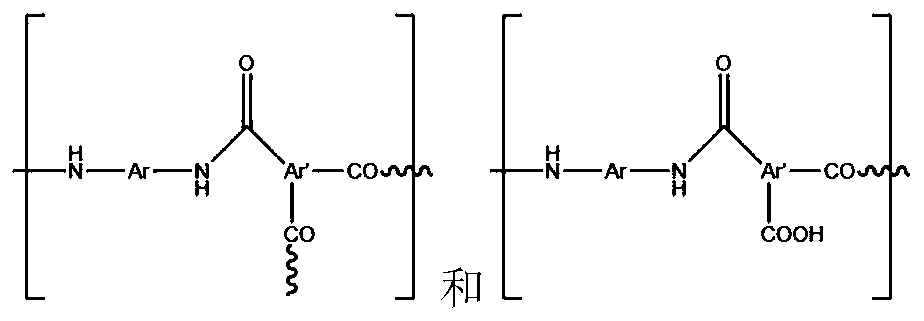

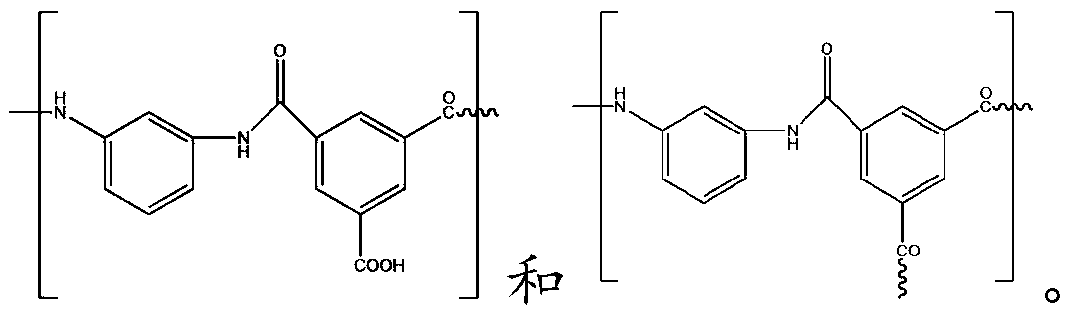

Hybrid composite membrane, preparation method and application thereof

A hybrid composite and compound technology, which is applied in the field of membrane separation, can solve the problems of low flux of solvent-resistant nanofiltration membranes, incompatibility, poor solvent resistance, etc., to improve stability and separation performance, improve flux, and improve affinity. The effect of water improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] After mixing the graphene oxide suspension aqueous solution with a concentration of 2 mg / L and ethylenediamine, it was ultrasonicated for 30 minutes, and then cross-linked at room temperature for at least 12 hours, and set aside.

[0090] The average sheet diameter of the GO is 500nm, and the average thickness is 2nm.

[0091] The film making steps are as follows:

[0092] Step 1: After fully contacting the base film with a polyethyleneimine solution with a concentration of 0.1wt% at 70°C for 30s, remove the modifier remaining on the surface of the base film, and dry it for 60s, then mix with the cross-linked graphene oxide Suspended aqueous solution is fully contacted for 60s, the free suspension on the surface of the membrane is removed, and dried to obtain a modified basement membrane;

[0093] Step 2: After fully contacting the modified basement membrane obtained in step 1 with the aqueous phase monomer solution for 120s, remove the aqueous phase monomer solution o...

Embodiment 2

[0098] The only difference from Example 1 is that the obtained cross-linked hybrid composite nanofiltration membrane containing a cross-linked graphene oxide intermediate layer was activated in activating reagent DMF at 80°C for 30min.

[0099] All other steps are the same as in Example 1; the test conditions are the same as in Example 1.

[0100] The prepared hybrid composite nanofiltration membrane has a retention rate of up to 97.49% to sodium sulfate, and the flux of water is 55.85LMH, which is much higher than that of the comparative example. Compared with Example 1, both the flux and the retention rate have been improved. The significant increase shows that the activation process dissolves some short-chain molecules and rearranges long-chain molecules, which greatly improves the separation performance of the membrane.

[0101] It can be seen that the present invention has achieved remarkable technical effects and progress.

Embodiment 3

[0103] The difference from Example 1 is that in step 1, the polyimide base film is fully contacted with 0.1wt% polyethyleneimine at 25°C for 30s.

[0104] All other steps are identical with embodiment 1; Test condition is identical with comparative example.

[0105] The average thickness of the separated cortex is 20nm, and the average roughness is 1.99nm.

[0106] The prepared hybrid composite nanofiltration membrane has a rejection rate of 96.69% for rhodamine B, and a flux of ethanol of 43.44LMH, which is much higher than that of the comparative example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com