Isobutylene refining kettle residue treating method

A processing method and technology for isobutene, applied in chemical instruments and methods, hydrocarbon purification/separation, chemical/physical processes, etc., can solve the problems of high operating temperature, low economic value, recovery of isobutene, etc. Green chemical industry, the effect of reducing pollution discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

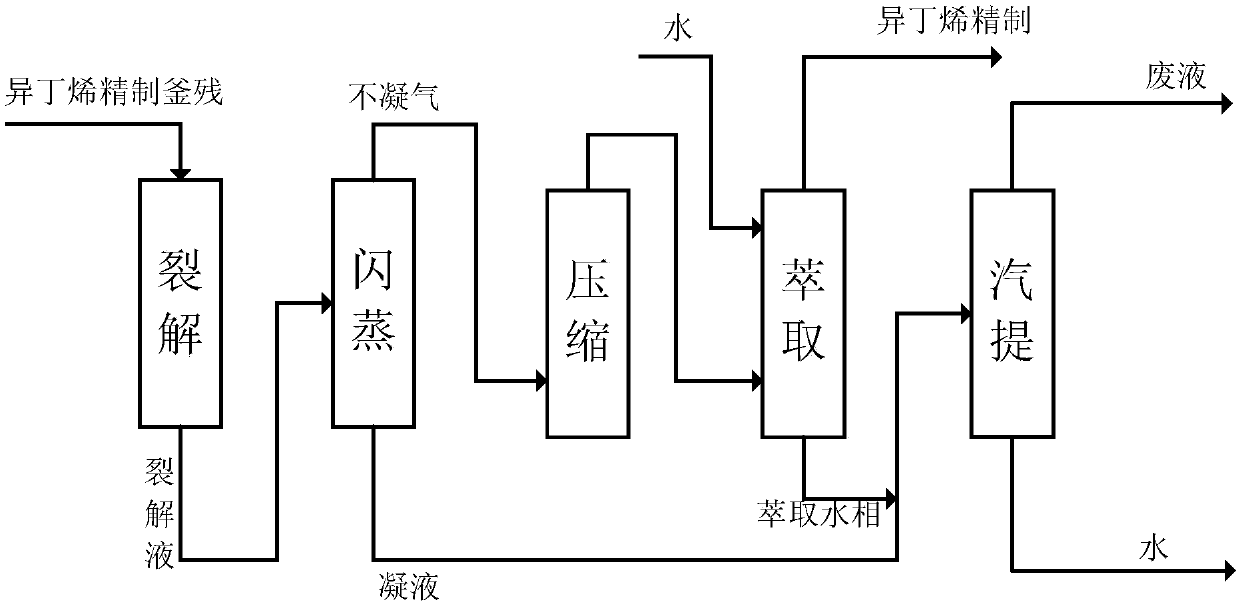

Method used

Image

Examples

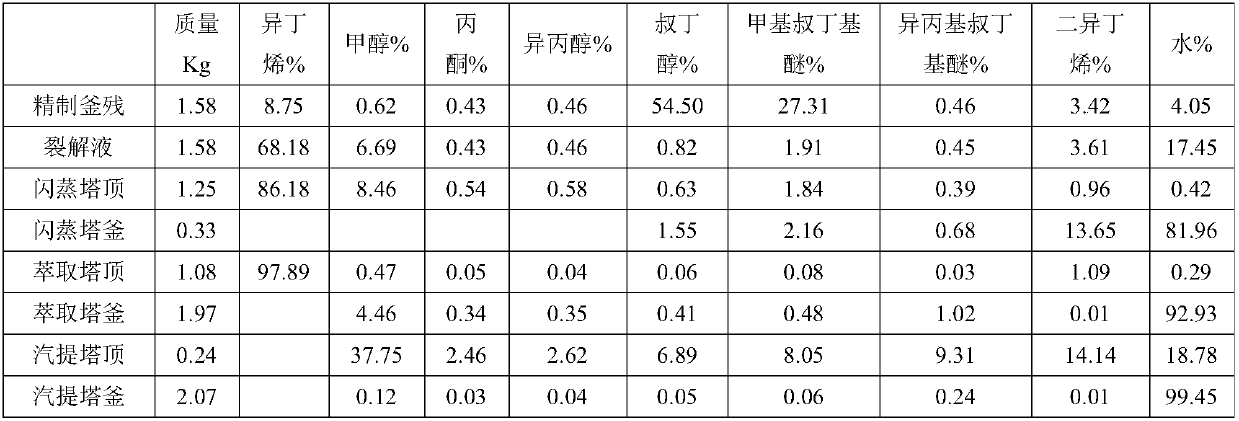

Embodiment 1

[0048] 290g Co(NO 3 ) 2 6(H 2 O) (1mol) and 19.3g quinoline (0.15mol) and 224.3g terephthalic acid (1.35mol) were dissolved in 1L of water, mixed evenly and then transferred to a 2L reactor at 230°C for 60h at a constant temperature, and the obtained precipitate was dissolved in 0.8L nitromethane, and add 0.3molH 2 SO 4 and 0.4molTf 2 O, stirred at 30°C for 1h, cooled the reaction liquid to -10°C to precipitate precipitates, filtered the precipitates, washed them with water and acetone in turn, and then roasted at 280°C for 6h to obtain the catalyst substrate, extruded into 3mm*5mm Particulate matter, whose composition is 37.5 wt% Co 2 o 3 , 50.8wt% terephthalic acid, 11.7wt% sulfoquinoline.

[0049] Load the catalyst into a Ф40cm fixed-bed reactor with an operating pressure of 0.9MPa, a temperature of 135°C, and a space velocity of 2.3h for isobutylene refining residue -1 , the lysate is flashed at 0.3MPa, and the crude isobutene compressed liquid obtained after the c...

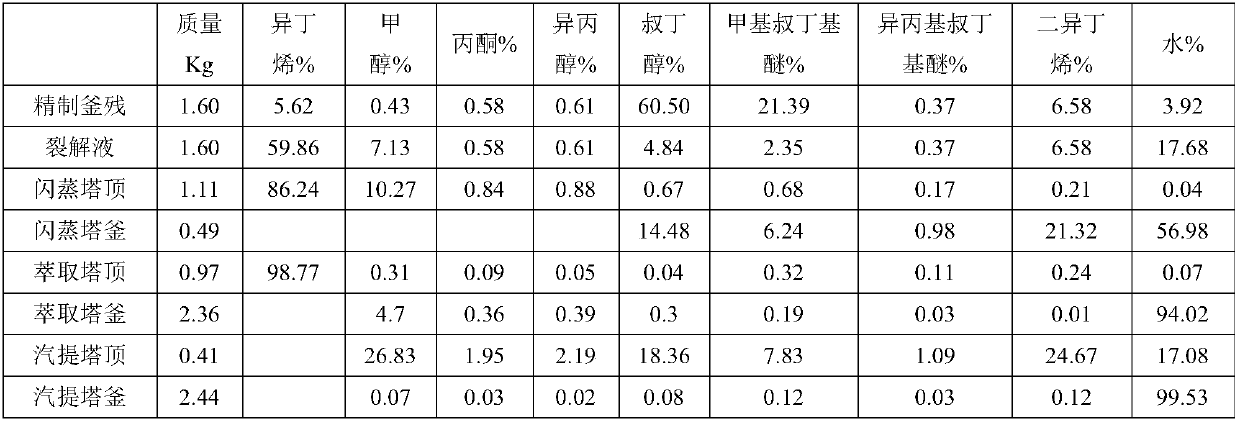

Embodiment 2

[0053] 287g Mn(NO 3 ) 2 6(H 2 O) (1mol) and 19.8g of pyridine (0.25mol), 273.9g of terephthalic acid (1.65mol) were dissolved in 1L of water, mixed evenly and then transferred to a 2L reactor at a constant temperature of 180°C for 90h, and the obtained precipitate was dissolved in 1.0 L nitromethane, and add 0.4molH 2 SO 4 and 0.5molTf 2 O, stirred at 35°C for 1.6h, cooled the reaction solution to -25°C to precipitate precipitates, filtered the precipitates, washed them with water and acetone in turn, and then roasted at 240°C for 8h to obtain a catalyst matrix, extruded into 3mm*5mm particulate matter, whose composition is 20.6wt% MnO 2 , 65.1wt% terephthalic acid, 14.3wt% pyridine sulfonate.

[0054] Load the catalyst into a Ф40cm fixed-bed reactor with an operating pressure of 1.4MPa, a temperature of 160°C, and a space velocity of 0.8h -1 , the cracked reaction solution is flashed at 0.5MPa, and the non-condensable gas at the top of the flash column is compressed to...

Embodiment 3

[0058] 288gFe(NO 3 ) 2 6(H 2 O) (1mol) and 6.8g of imidazole (0.1mol), 133.2.g of 1,3,5-benzenetricarboxylic acid (0.8mol) were dissolved in 1L of water, mixed evenly and then transferred to a 2L reaction kettle at 230°C for 60h. The resulting precipitate was dissolved in 0.8L nitromethane, and 0.2molH 2 SO 4 and 0.3molTf 2 O, Stir at 40°C for 1h, cool the reaction solution to -15°C to precipitate precipitates, filter the precipitates, wash with water and acetone in turn, and then roast at 300°C for 4h to obtain a catalyst substrate, extruded into 3mm*5mm Particulate matter, whose composition is 44.7 wt% Fe 2 o 3 , 47.0wt% 1,3,5-benzenetricarboxylic acid, 8.3wt% sulfoimidazole.

[0059] Load the catalyst into a Ф40cm fixed-bed reactor with an operating pressure of 1.2MPa, a temperature of 145°C, and a space velocity of 1.5h -1 , the cracked reaction solution was flashed at 0.2MPa, and the non-condensable gas at the top of the flash column was compressed to obtain a cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com