Carbon-coated polysulfide heterojunction material, preparation method and application

A technology of sulfide and heterojunction, applied in the direction of electrical components, structural parts, electrochemical generators, etc., can solve the problems of complex preparation methods, limited heterogeneous interface, and inability to express, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Fe 2 o 3 / ZnO precursor preparation: Dissolve 16g of anhydrous ferric chloride and 14g of anhydrous zinc chloride in a mixture of 500ml deionized water and 100ml alcohol, then pour 5g of lithium hydroxide monohydrate and slowly drop 40mL Hydrogen peroxide, stirring continuously for 2h. After separation, washing and drying, a multivariate mixture is obtained. Get 10g of the mixture, mix and grind it evenly with 4.5g of anhydrous lithium chloride and 5.5g of anhydrous potassium chloride, then transfer it to a muffle furnace, and heat it at 450°C for 2 h under air conditions, so that Fe 2 o 3 Mix well with ZnO in molten salt environment. Finally, the soluble salt is removed by washing with water. The salt can be recycled, filtered and dried to obtain Fe 2 o 3 / ZnO precursor powder.

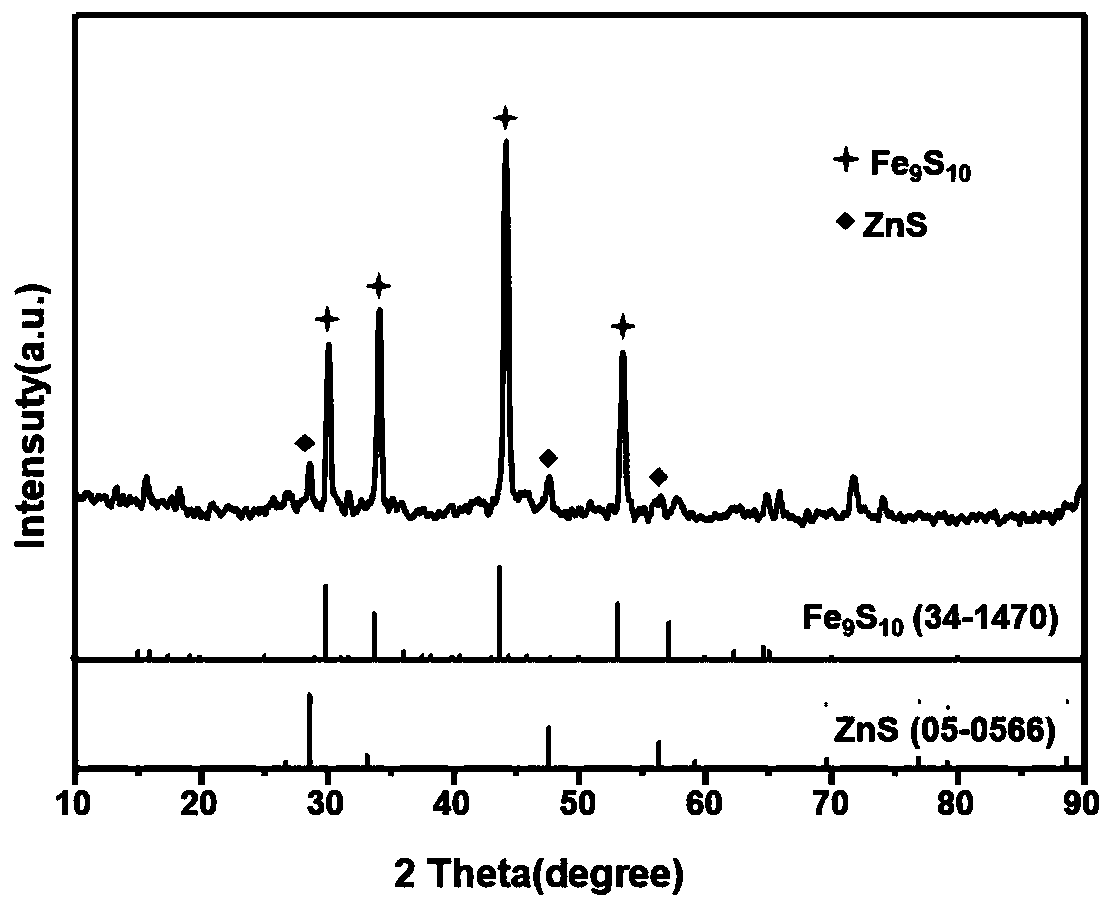

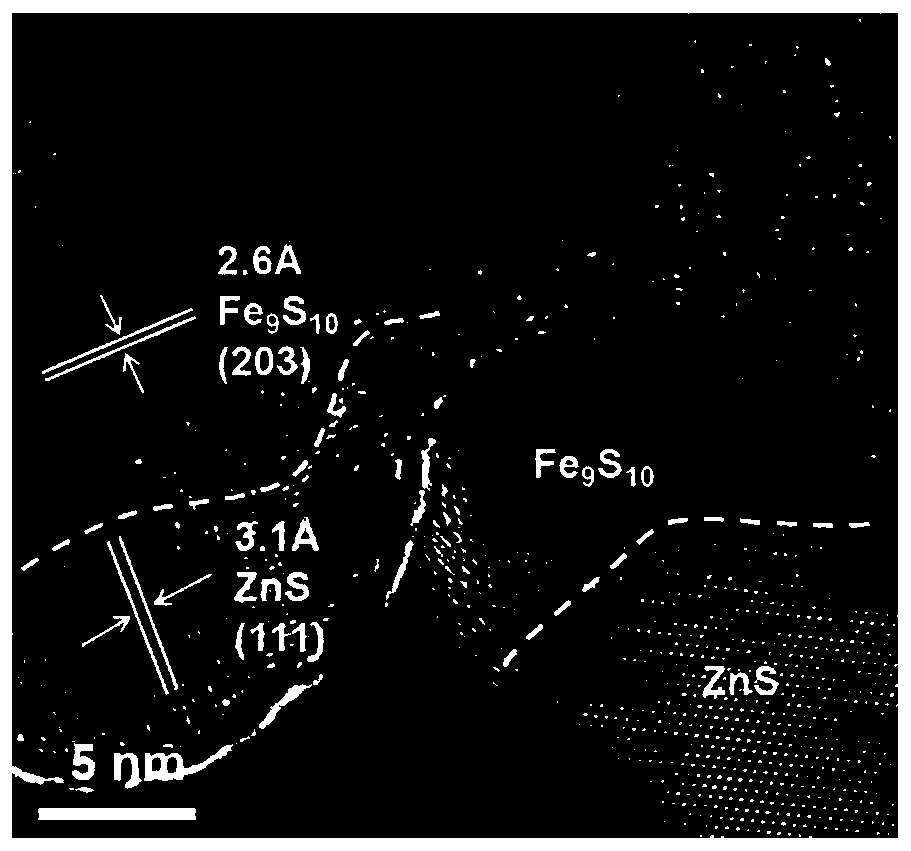

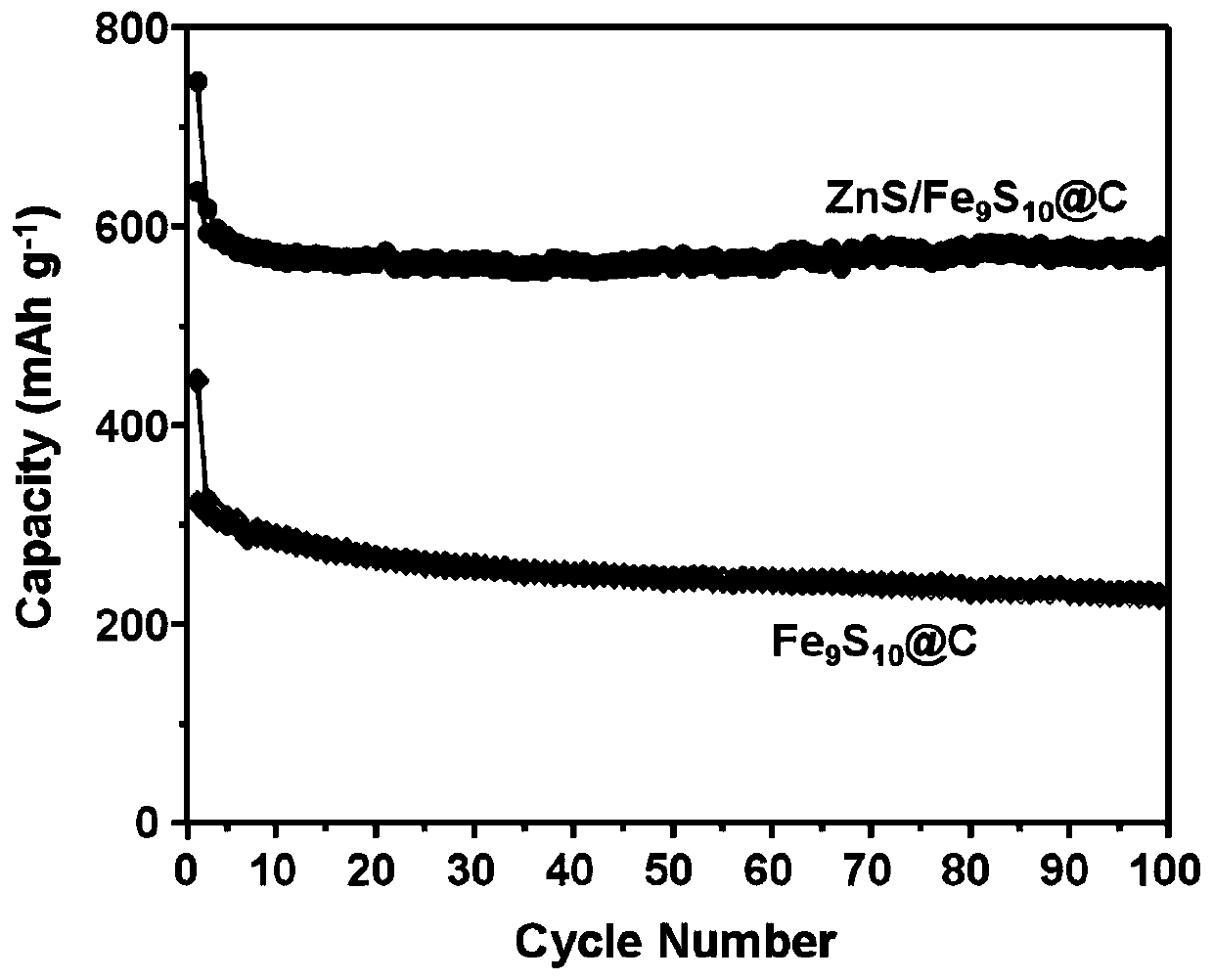

[0033] Carbon coated Fe 9 S 10 / ZnS heterojunction preparation: take 6g Fe 2 o 3 / ZnO precursor powder was ultrasonically dispersed in 200mL Tris solution with pH=8.5, and 2g of dop...

Embodiment 2

[0037] SnO 2 / ZnO precursor preparation: Dissolve 10g of anhydrous stannous chloride and 20g of anhydrous zinc chloride in a mixture of 500ml deionized water and 100ml alcohol, then pour 5g of sodium hydroxide monohydrate and slowly drop 40mL of hydrogen peroxide, stirring continuously for 2h. After separation, washing and drying, a multivariate mixture is obtained. Take 10g of the mixture and mix it with 6g of anhydrous sodium chloride and 4g of anhydrous potassium chloride and grind it evenly, then transfer it to a muffle furnace, and heat it at 450°C for 2 h under air conditions, so that the SnO 2 Mix well with ZnO in molten salt environment. Finally, the soluble salt is removed by washing with water. The salt can be recycled, filtered and dried to obtain SnO 2 / ZnO precursor powder.

[0038] Carbon coated Sn 2 S 3 / ZnS heterojunction preparation: take 6g SnO 2 / ZnO precursor powder was ultrasonically dispersed in 200mL aqueous solution, and 2g glucose was added unde...

Embodiment 3

[0041] MoO 3 / Fe 2 o 3 Preparation of the precursor: Dissolve 15g of anhydrous ferric chloride and 15g of ammonium molybdate tetrahydrate in a mixture of 500ml of deionized water and 100ml of alcohol, then pour in 5g of lithium hydroxide monohydrate and slowly dropwise add 40mL of hydrogen peroxide , and continued stirring for 2h. After separation, washing and drying, a multivariate mixture is obtained. Get 10g of mixture and 7.5g of anhydrous sodium chloride and 2.5g of anhydrous calcium chloride, mix and grind evenly, then transfer to the muffle furnace, heat treatment at 350°C for 4h under air conditions, so that Fe 2 o 3 and MoO 3 Mix well in a molten salt environment. Finally, the soluble salt is removed by washing with water. The salt can be recycled, filtered and dried to obtain MoO 3 / Fe 2 o 3 Precursor powder.

[0042] Carbon-coated MoS 2 / Fe 9 S 10 Preparation of heterojunction: Take 6g MoO 3 / Fe 2 o 3 The precursor powder was ultrasonically dispersed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse capacity | aaaaa | aaaaa |

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com