Water-dispersible glass fiber coating polymer and preparation method thereof

A polymer and glass fiber technology, which is applied in the field of water-dispersed glass fiber coating polymer and its preparation, can solve the problems of poor alkali resistance, poor storage stability, poor overall performance and cost performance, and achieves good water solubility and good performance. The effect of water resistance and good polymerization stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

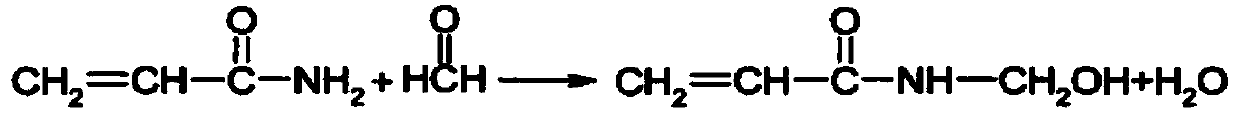

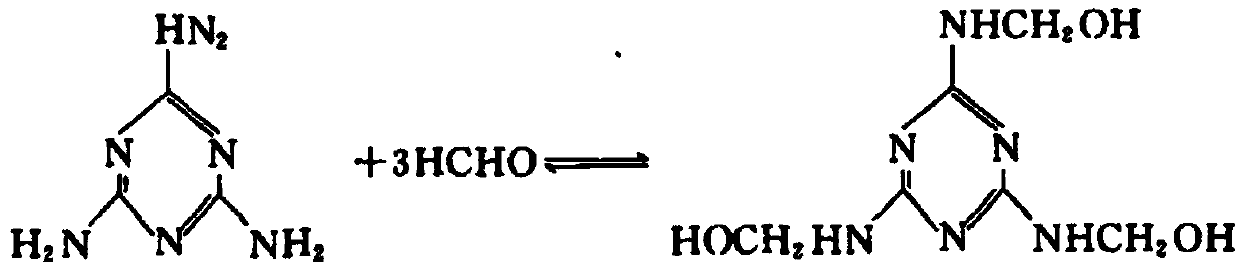

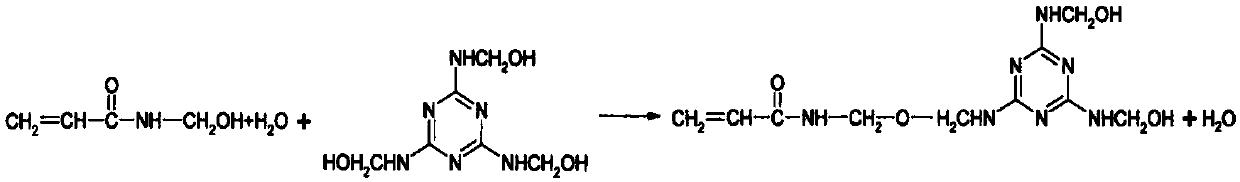

[0061] 2. Preparation of modified micro-crosslinked urea-formaldehyde resin glue

[0062] (1) Raw material ratio of modified urea-formaldehyde resin glue

[0063] Wherein the molar ratio of the total amount of formaldehyde: urea: melamine: acrylamide used is 2:1.4:0.4:0.2.

[0064] (2) The formula of modified urea-formaldehyde resin is shown in the following table 2:

[0065] Table 2. Formula of modified urea-formaldehyde resin glue

[0066] raw material name

Dosage (kg)

formaldehyde

171.5

Urea (1)

67.2

Urea (2)

16.8

14

50.4

20% NaOH

Appropriate amount

Appropriate amount

5

mixed solvent

some

[0067] (3) Preparation process of modified urea-formaldehyde resin glue

[0068] Add the first batch of formaldehyde into the 500L reactor, stir, and adjust its pH to 8.5-9, then add the first batch of urea, heat to 90°C and...

Embodiment 1

[0070] A kind of preparation method of urea-formaldehyde resin modified acrylate self-crosslinking water dispersion system polymer comprises the following steps (the following proportioning is weight part, unit is kilogram):

[0071] 1. Recipe

[0072] The formula includes a core polymerization part, a shell polymerization part and a neutralized dispersed phase, and the raw material components include the following;

[0073] The core polymerization part includes: 18 for methyl methacrylate, 35 for hydroxyethyl acrylate, 22 for butyl acrylate, 35 for ethyl acrylate, 2 for N-(N-butoxymethyl)acrylamide, Acrylic acid glycidyl ether is 2, azobisisobutyronitrile is 2;

[0074] The shell polymerization part includes: 8 for acrylonitrile, 18 for hydroxypropyl acrylate, 10 for methyl methacrylate, 16 for tert-butyl methacrylate, 12 for butyl acrylate, 10 for methacrylic acid, and 10 for azobis Isobutyronitrile is 1.1, modified urea-formaldehyde resin is 74;

[0075] The neutralized ...

Embodiment 2

[0082] A kind of preparation method of urea-formaldehyde resin modified acrylate self-crosslinking water dispersion system polymer comprises the following steps (the following proportioning is weight part, unit is kilogram):

[0083] 1. Recipe

[0084] The formula includes a core polymerization part, a shell polymerization part and a neutralized dispersed phase, and the raw material components include the following;

[0085] The core polymerization part includes: 35 for styrene, 41 for hydroxyethyl methacrylate, 22 for butyl acrylate, 6 for tert-methyl methacrylate, 24 for isooctyl methacrylate, and 24 for glycidyl methacrylate 2, di-tert-butyl peroxide is 3;

[0086] The shell polymerization part includes: 18 for hydroxyethyl methacrylate, 10 for methyl methacrylate, 15 for butyl acrylate, 5 for acrylic acid, 5 for itaconic acid, 2 for di-tert-butyl peroxide, modified Urea-formaldehyde resin is 42;

[0087] The neutralized dispersed phase includes: 6.5 for N,N-dimethyletha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com