A kind of preparation method of epoxy succinic acid polymer containing sulfonic acid group

An epoxy succinic acid, sulfonic acid group-containing technology, applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc., can solve problems such as environmental impact, and achieve high conversion rate of polymerization reaction , good scale inhibition performance and the effect of dispersing iron oxide performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

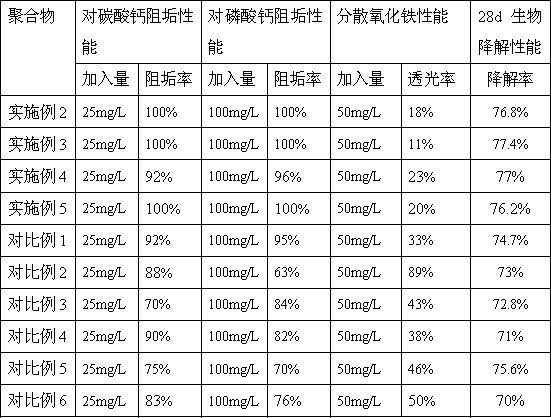

Examples

Embodiment 1

[0025] The preparation of embodiment 1 epoxy succinic acid

[0026] A certain amount of maleic anhydride and deionized water are mixed, and the addition of deionized water is 1.5 times of the amount of maleic anhydride water, stirred until dissolved, slowly adding a mass fraction of 50% sodium hydroxide solution in the solution, its The mass is 1.5 times the mass of the raw material maleic anhydride, and the temperature of the solution is controlled below 55°C to hydrolyze the maleic anhydride into maleate, and then heated to 55°C, adding catalyst sodium tungstate, the mass of sodium tungstate is horse 8% of the total mass of anhydride and sodium hydroxide, then slowly add 30% hydrogen peroxide, the amount of hydrogen peroxide added is 2.5 times the mass of the raw material, during the dropwise addition, the pH value is controlled between 4 and 5.5, and the temperature is raised to 85 ℃, epoxidation for 1.5h, stopped heating and white crystals precipitated, waited for the reac...

Embodiment 2

[0028] Weigh a certain amount of epoxysuccinic acid (ESA), itaconic acid (IA), and sodium methacrylate sulfonate (SMAS) prepared in Example 1, the ratio is ESA:IA:SMAS=2:2:1, add In the four-necked flask, and add a certain amount of distilled water, the add-on of deionized water is about the sum of the total mass of raw materials, the add-on of ammonium persulfate is 5% of the total mass of raw materials, and the add-on of isopropanol is the total mass of raw materials 10% of the 10% of the water bath, heated to 96 ° C, using two syringe pumps to drop the concentration of 10% sodium bisulfite solution and the concentration of 30% hydrogen peroxide at the same time, the addition of sodium bisulfite solution and hydrogen peroxide is the total amount of raw materials 15% of the mass. Set the rate of addition so that the addition of the two is completed within 1 h at the same time. The reaction was continued at 96° C. for 5 hours, and after cooling down to room temperature, a lig...

Embodiment 3

[0030] Weigh a certain amount of epoxysuccinic acid (ESA), itaconic acid (IA), and sodium methacrylate sulfonate (SMAS) prepared in Example 1, the ratio is ESA:IA:SMAS=2:2:1, add In the four-necked flask, and add a certain amount of distilled water, the add-on of deionized water is about the sum of the total mass of raw materials, the add-on of ammonium persulfate is 5% of the total mass of raw materials, and the add-on of isopropanol is the total mass of raw materials 15% of 15%, water bath heated to 96 ℃, with two syringe pumps dropwise at the same time 10% concentration of sodium bisulfite solution and 30% concentration of hydrogen peroxide, the addition of sodium bisulfite solution and hydrogen peroxide is the total amount of raw materials 20% of the mass. Set the dropping rate so that the two drops are completed simultaneously within 1.5 hours. The reaction was continued at 96° C. for 6 hours, and after cooling down to room temperature, a light yellow transparent liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com