Synthesis method of DL-homocysteine thiolactone hydrochloride

A technology for the synthesis of cystine thiolactone and its synthesis method, which is applied in the field of synthesis of DL-homocysteine thiolactone hydrochloride, which can solve the problems of polluted environment, dangerous operation, large amounts of hydrogen waste water, etc., and achieve cathode activity High, improve productivity, improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of the cathode electrode in the electrolytic cell: the entire surface of the glassy carbon electrode is roughened to a roughness of 10 microns to obtain a substrate, and the surface roughness is measured by a stylus-type roughness meter, and the average is calculated using the JIS B0601:2001 standard roughness. Grind the lead-bismuth alloy powder and place it in a CVD furnace, pass argon gas at a rate of 5 sccm, place the substrate downstream of the argon gas, raise the temperature to 650 °C at a heating rate of 25 °C / min, keep it warm for 1 hour, and then cool it down. A lead-bismuth alloy thin film is formed on the base material to obtain a cathode electrode, a titanium plate is used as an anode, and the cathode electrode and the anode electrode are applied to an ion diaphragm electrolytic cell.

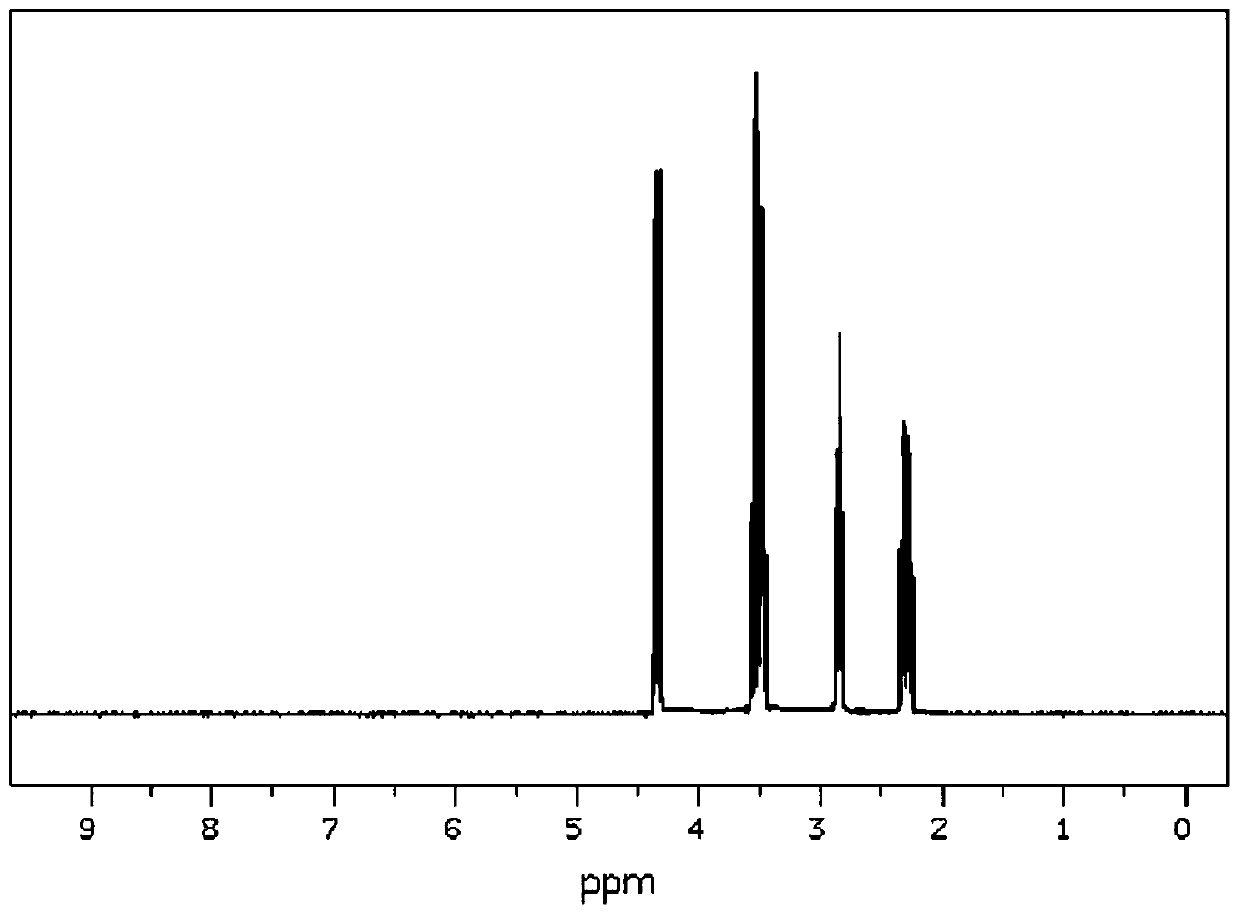

[0026] 200kg DL-homocystine is completely dissolved in a hydrochloric acid solution with a mass fraction of 8%, and a total of about 373L of catholyte is used. T...

Embodiment 2

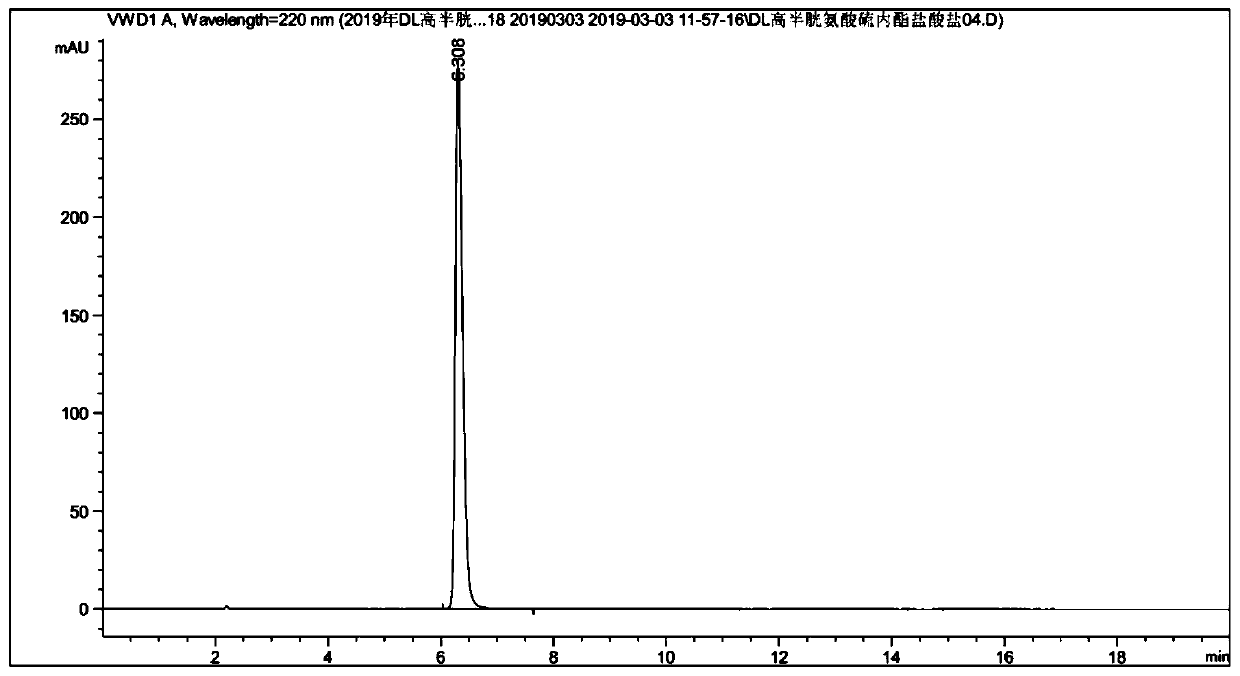

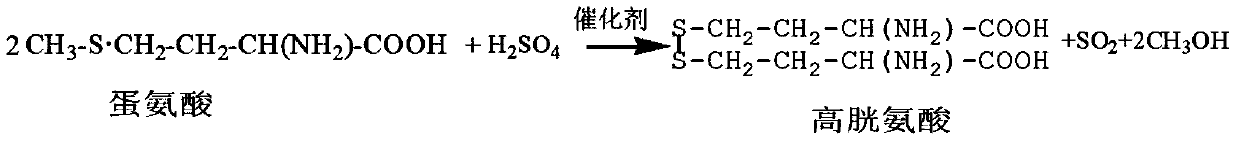

[0030] Add 300kg DL-methionine, 750kg concentrated sulfuric acid with a mass fraction of 98%, and 90kg nickel-based metal-supported catalyst to the autoclave, pressurize to 2Mpa, control the temperature at 120°C, and react for 7 hours to obtain a hydrolyzate; The solution was adjusted to pH 5 with 30% sodium hydroxide solution, decolorized with 4kg of activated carbon, filtered after decolorization, concentrated and crystallized the filtrate, rinsed twice with alcohol, and dried to obtain 196.1kg of DL-homocystine Acid, the product yield of DL-homocysteine is 72.7% (based on DL-methionine), and its purity is 99.9%.

[0031] Preparation of the cathode electrode in the electrolytic cell: the entire surface of the glassy carbon electrode is roughened to a roughness of 10 microns to obtain a substrate, and the surface roughness is measured by a stylus-type roughness meter, and the average is calculated using the JIS B0601:2001 standard roughness. Grind the lead-bismuth alloy po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com