Method for preparing DFN package device with high thermal conductivity

A packaging device, high thermal conductivity technology, applied in semiconductor/solid-state device manufacturing, semiconductor device, semiconductor/solid-state device components and other directions, can solve the problems of uneven curing, poor fluidity of epoxy resin composition, and reduced thermal performance, etc. Achieve the effect of improving the heat dissipation effect of the package, improving the heat dissipation effect, and improving the quality of the package

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

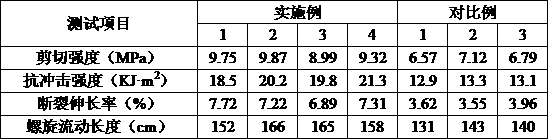

Embodiment 1~4

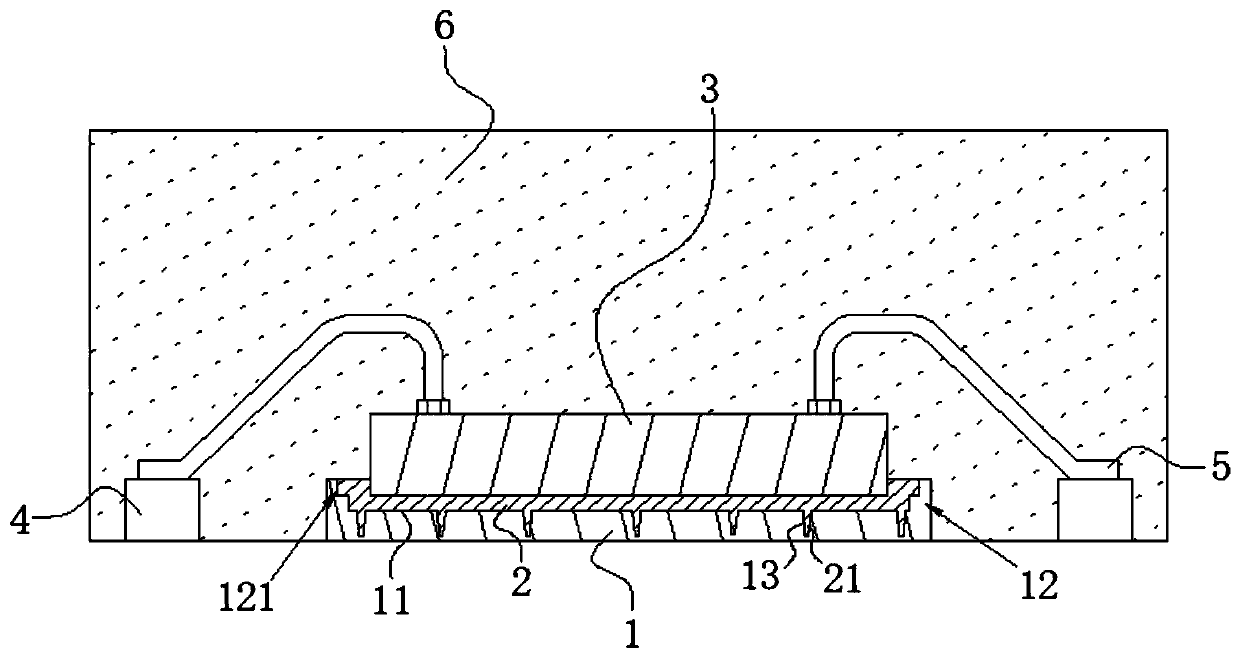

[0027] Embodiments 1 to 4: A preparation method of a high thermal conductivity DFN packaged device, the high thermal conductivity DFN packaged device includes a heat dissipation pad 1, a chip 3 and a conductive pad 4 located in an epoxy insulator 6, and the chip 3 is located in On the heat dissipation pad 1, several conductive pads 4 are arranged around the heat dissipation pad 1, and the conductive pads 4 and the chip 3 are connected by a lead 5;

[0028] The central area of the heat dissipation pad 1 is provided with a sunken groove 11 for embedding the chip 3, thereby forming a cofferdam portion 12 at the edge area of the heat dissipation pad 1, and the bottom of the sunken groove 11 and the cofferdam portion 12 are in contact with the chip. A silver paste layer 2 is provided between the lower surface and the side wall of the 3, and a number of heat exchange blind holes 13 extending into the heat dissipation pad 1 are opened at the bottom of the sinker 11, and in the hea...

Embodiment 1

[0040] The release agent in embodiment 1 is stearic acid, and flame retardant is borate; The release agent in embodiment 2 is stearate, and flame retardant is borate; The release agent in embodiment 3 The agent is oxidized polyethylene wax, and the flame retardant is molybdate; the release agent in Example 4 is a mixture of stearic acid and oxidized polyethylene wax, and the flame retardant is molybdate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com