Meso-porous silica particle supported amidoxime polymer uranium-absorbing material and preparation method thereof

A technology of mesoporous silica gel and adsorption material, which is applied in the preparation of uranium compounds, uranium compounds, alkali metal compounds, etc. The effect of large-scale production and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

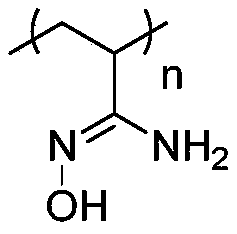

AI Technical Summary

Problems solved by technology

Method used

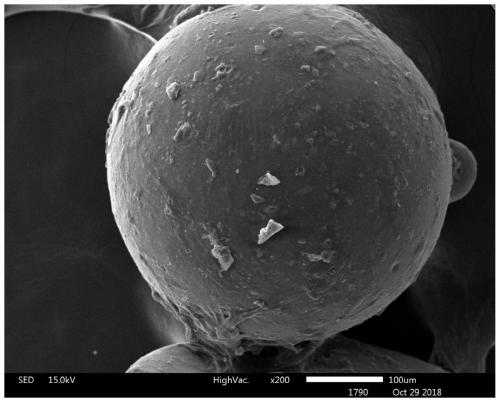

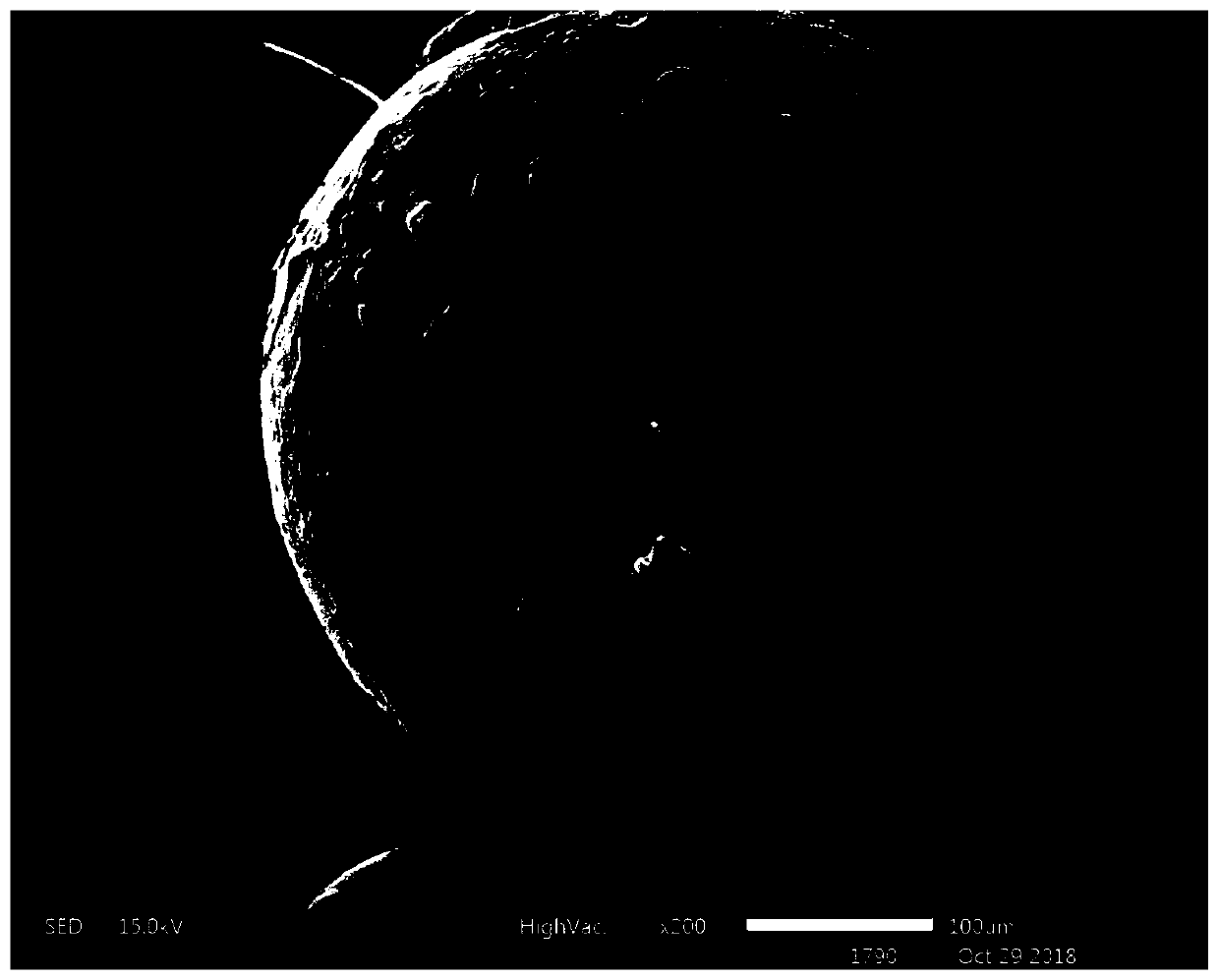

Image

Examples

Embodiment 1

[0029] Step 1: Weigh 100g of polyacrylonitrile powder and 26g of lithium chloride particles into a 1L beaker, then add 600mL of N,N-dimethylformamide into it and stir until completely dissolved. Take 52g of the above-mentioned polyacrylonitrile solution and add it into 30g of 50 mesh mesoporous silica gel particles, stir evenly, and degas under reduced pressure. The above defoamed mixture was poured into a three-necked flask equipped with a stirrer and 500 mL of water, and stirred at 3000 rpm for 2 h. Afterwards, the solid was filtered out and dried in an oven for 24 hours to obtain mesoporous silica particles coated with polyacrylonitrile.

[0030] Step 2: Add 500mL of methanol-water with a volume ratio of 1:1 to a 1L Erlenmeyer flask containing 10g of hydroxylamine hydrochloride and 8g of sodium carbonate, and stir at room temperature until completely dissolved. Put 50 g of the mesoporous silica gel particles coated with polyacrylonitrile prepared in the first step into the...

Embodiment 2

[0033] Step 1: Weigh 100g of polyacrylonitrile powder and 26g of polyvinylpyrrolidone into a 1L beaker, then add 600mL of dimethyl sulfoxide into it and stir until completely dissolved. Take 52g of the above-mentioned polyacrylonitrile solution and add it into 30g of 50 mesh mesoporous silica gel particles, stir evenly, and degas under reduced pressure. The above defoamed mixture was poured into a three-necked flask equipped with a stirrer and 500 mL of water, and stirred at 3000 rpm for 2 h. Afterwards, the solid was filtered out and dried in an oven for 24 hours to prepare mesoporous silica particles coated with polyacrylonitrile.

[0034] Step 2: Add 500mL of methanol-water with a volume ratio of 1:1 to a 1L Erlenmeyer flask containing 10g of hydroxylamine hydrochloride and 8g of sodium carbonate, and stir at room temperature until completely dissolved. 55 g of mesoporous silica gel particles coated with polyacrylonitrile prepared in the first step were put into the above-...

Embodiment 3

[0037] Step 1: Weigh 75g of polyacrylonitrile powder and 30g of ammonium chloride into a 1L beaker, then add 450mL of dimethyl sulfoxide into it and stir until completely dissolved. Take 40 g of the above polyacrylonitrile solution and add it into 30 g of 50 mesh mesoporous silica gel particles, stir evenly, and degas under reduced pressure. The above defoamed mixture was poured into a three-necked flask equipped with a stirrer and 500 mL of water, and stirred at 3000 rpm for 2 h. Afterwards, the solid was filtered out and dried in an oven for 24 hours to obtain mesoporous silica particles coated with polyacrylonitrile.

[0038] Step 2: Add 500mL of methanol-water with a volume ratio of 1:1 to a 1L Erlenmeyer flask containing 10g of hydroxylamine hydrochloride and 8g of sodium carbonate, and stir at room temperature until completely dissolved. Put 50 g of the mesoporous silica gel particles coated with polyacrylonitrile prepared in the first step into the above-mentioned Erle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com