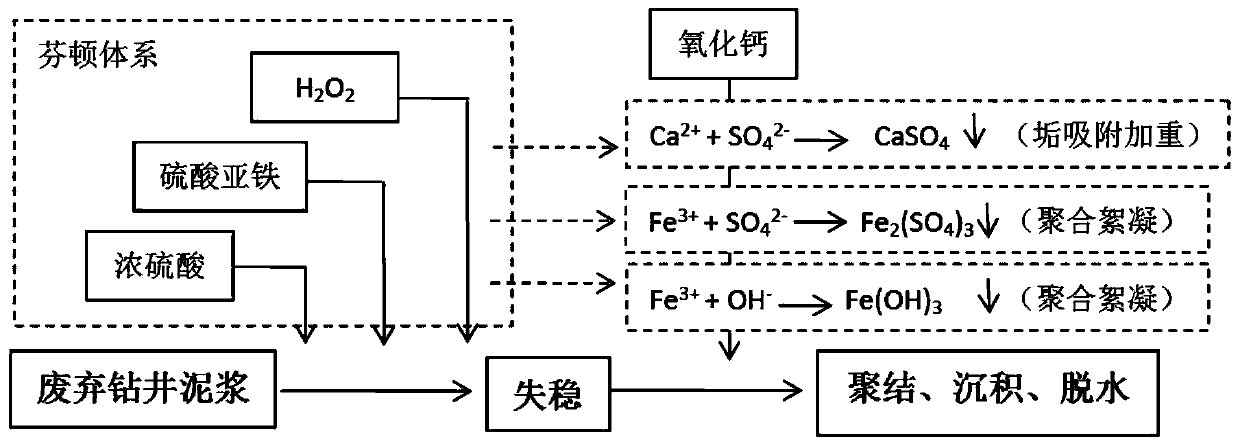

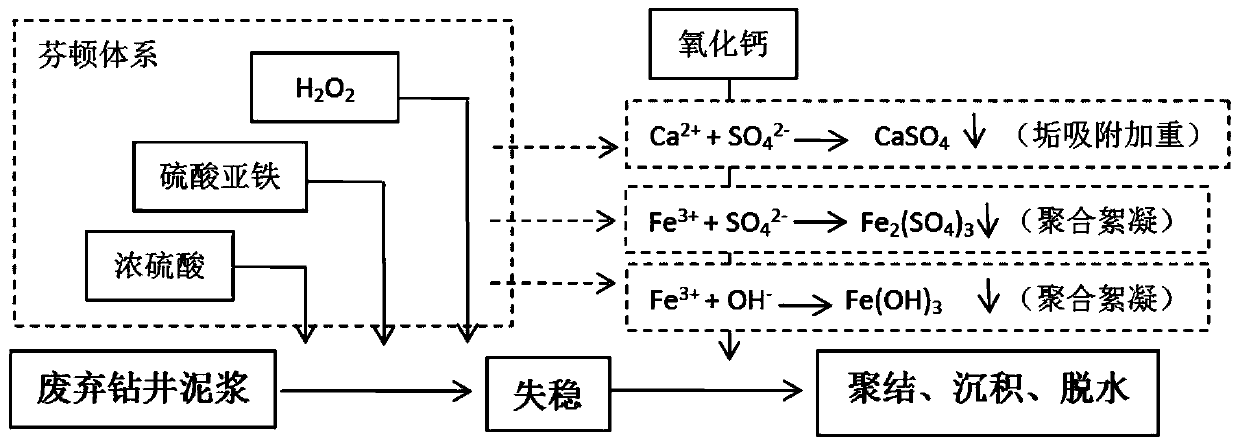

Method for dehydrating waste drilling mud on the basis of Fenton oxidation destabilization and scale adsorption weighted coupling

A drilling mud, Fenton oxidation technology, applied in chemical instruments and methods, mining wastewater treatment, water/sludge/sewage treatment, etc. The effect of short, large pollutant reduction capacity and low usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Take 1000mL of waste drilling mud (water content 65.25%, oil content 3.38%, solid content 31.37%), under constant stirring, first adjust its pH to 3 with concentrated sulfuric acid, then add 180mg ferrous sulfate, 3mL The hydrogen peroxide with a mass concentration of 30% was continuously stirred for 56 minutes, then calcium oxide was added to adjust the pH to 10, the stirring was stopped after 5 minutes, and centrifuged at 2500 r / min for 10 minutes. After treatment, the dehydration rate was 77.15%, the content of suspended matter in the extracted water was 35.21mg / L, the oil content was 2.19mg / L, and the COD was 215.71mg / L; the water content of the bottom sediment was 29.23%, and the oil content was 6.18%.

Embodiment 2

[0021] Take 1000mL of waste drilling mud (water content 45.78%, oil content 24.25%, solid content 29.97%), under constant speed stirring, first adjust its pH to 3 with concentrated sulfuric acid, then add 120mg ferrous sulfate, 120mg Vitamin C and 3mL hydrogen peroxide with a mass concentration of 30% were stirred continuously for 32 minutes, then calcium oxide was added to adjust the pH to 10, the stirring was stopped after 5 minutes, and centrifuged at 2500 r / min for 10 minutes. After treatment, the dehydration rate was 65.23%, the content of suspended matter in the extracted water was 68.79mg / L, the oil content was 17.51mg / L, and the COD was 247.08mg / L; the water content of the bottom sediment was 21.27%, and the oil content was 33.32%.

Embodiment 3

[0023] Take 1000mL of waste drilling mud (water content is 81.22%, oil content is 10.09%, solid content is 8.69%), under constant speed stirring, at first adjust its pH to be 3 with concentrated sulfuric acid, then add 120mg ferrous sulfate, 120mg Vitamin C and 3mL hydrogen peroxide with a mass concentration of 30% were continuously stirred for 29 minutes, then a mixture of calcium oxide and sodium hydroxide with a mass ratio of 1:1 was added to adjust the pH to 10, the stirring was stopped after 5 minutes, and centrifuged at 2500r / min for 10 minutes. After treatment, the dehydration rate is 91.37%, the content of suspended solids in the extracted water is 123.40mg / L, the oil content is 10.13mg / L, and the COD is 174.85mg / L; the water content of the bottom sediment is 27.91%, and the oil content is 37.19%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com