Biomass gasifying coupled coal-fired boiler full-load SCR denitration system and technique

A technology for coal-fired boilers and gasification systems, applied in gasification processes, chemical instruments and methods, separation methods, etc., can solve the problems of high ammonia escape rate, poor catalyst activity, limited flue gas temperature, etc., and improve the energy structure. , the effect of increasing flue gas temperature and increasing power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

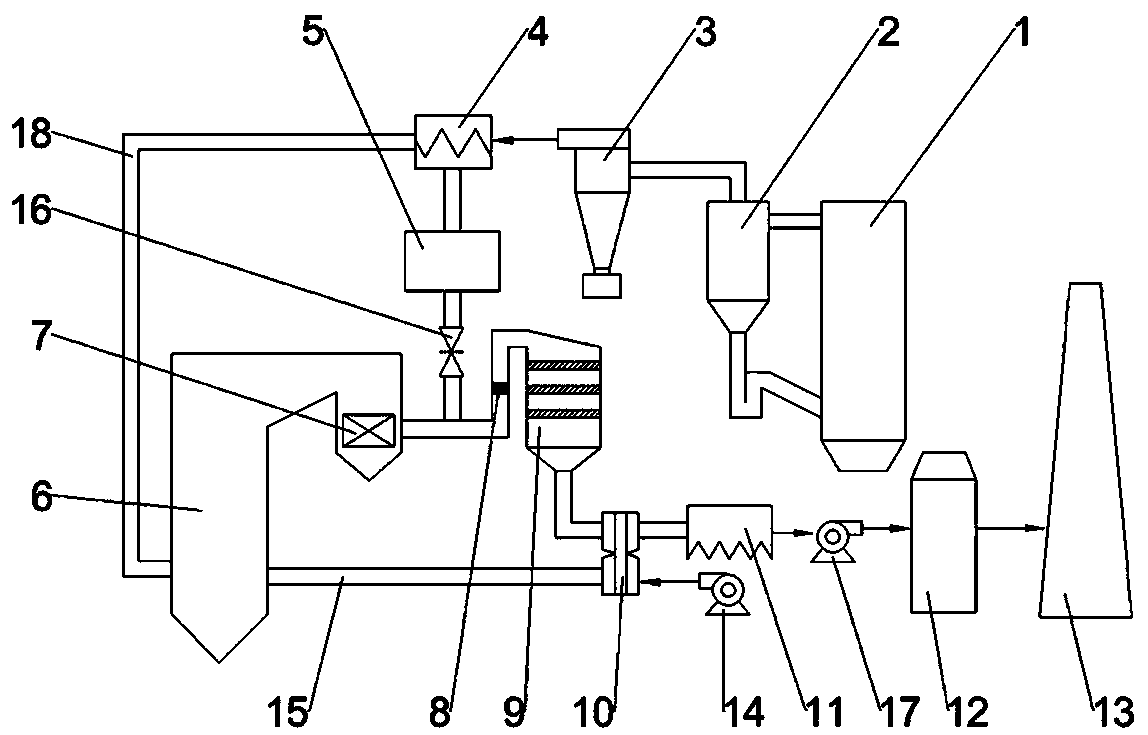

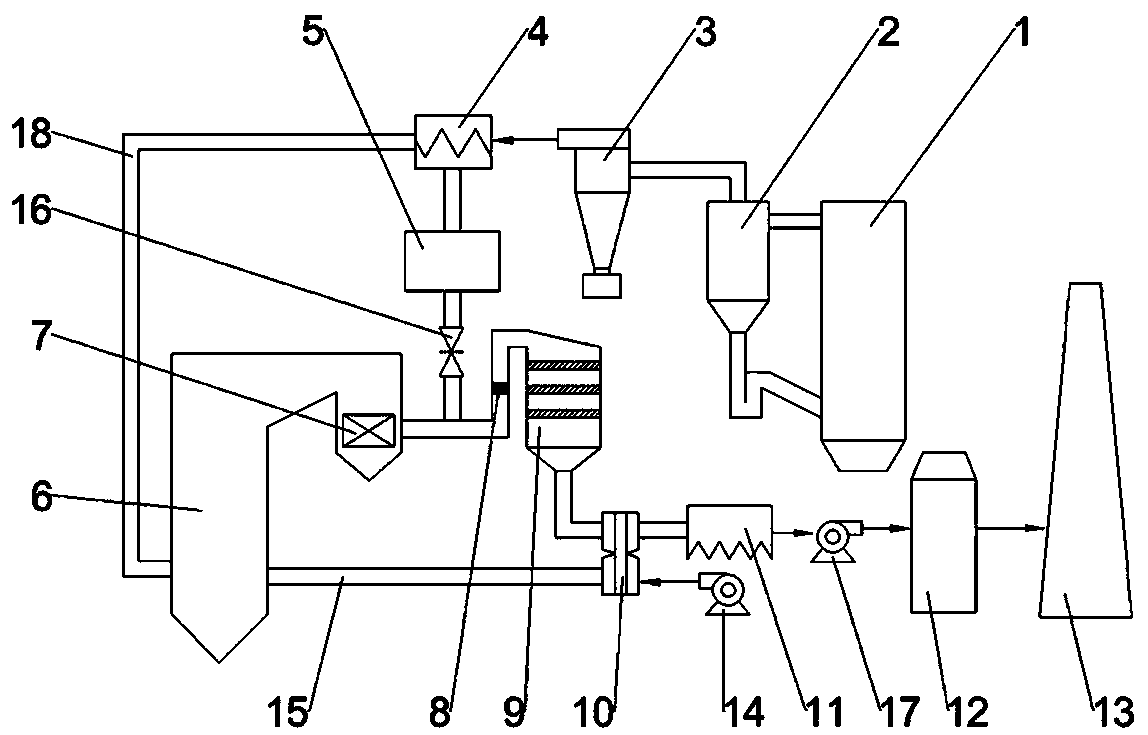

[0042] like figure 1 As shown, this embodiment provides a biomass gasification coupled coal-fired boiler full-load SCR denitrification system, including a biomass gasification system and a coal-fired boiler SCR denitrification system, and the biomass gasification system includes a biomass gasification Furnace 1 and coal-fired boiler 6, the gasification gas outlet of the biomass gasification furnace 1 is connected in turn with a cyclone separator 2, a cyclone dust collector 3, a heat exchanger 4 and a burner 5, and the gas outlet pipe of the heat exchanger 4 A hot gas delivery pipeline 18 connected to the coal-fired boiler 6 is also connected afterward; the SCR denitrification system of the coal-fired boiler includes a coal-fired boiler 6 and an economizer 7, and the tail of the coal-fired boiler 6 is connected to the economizer 7 device, The flue gas outlet of the economizer 7 is connected in sequence with the ammonia injection grid 8, the SCR denitrification reactor 9, the ai...

Embodiment 2

[0058] This embodiment provides an SCR denitrification process based on the full-load SCR denitrification system for biomass gasification coupled with coal-fired boilers described in Embodiment 1.

[0059] When the load of the coal-fired boiler 6 is operated below 50% (belongs to medium and low load operation), the temperature of the flue gas at the inlet of the SCR denitrification reactor 9 is only 250~270°C, which cannot reach the optimal reaction temperature of the SCR denitrification , it is necessary to add a heat source for heating the boiler flue gas. The specific process method is as follows:

[0060] After crushing and drying, the biomass is sent to the biomass circulating fluidized bed gasifier 1 through the feeding system for gasification. After the biomass is gasified, part of the dust and unreacted biomass raw materials in the gas are removed by the cyclone separator 2, and returned to the biomass circulating fluidized bed gasifier 1 through the feeding device to ...

Embodiment 3

[0064] This embodiment provides another SCR denitrification process based on the full-load SCR denitrification system for biomass gasification coupled with coal-fired boilers described in Embodiment 1.

[0065] When the load of the coal-fired boiler exceeds 50% (high load operation), the temperature of the flue gas at the entrance of the SCR denitrification reactor 9 is maintained at about 320°C, which can reach the optimal reaction temperature of the SCR denitrification. At this time, no additional Add a heat source to heat the flue gas, and the electric gate valve 16 is closed. However, the above-mentioned biomass gasification device and coal-fired boiler can be reasonably used to couple power generation, which can save coal and consume biomass resources. The specific process is as follows:

[0066] After crushing and drying, the biomass is sent to the biomass circulating fluidized bed gasifier 1 through the feeding system for gasification. After the biomass is gasified, par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com