A kind of quaternary phosphonium type deep eutectic ionic liquid catalyzes the method for coupling carbon dioxide and epoxide to prepare cyclic carbonate

A cyclic carbonate, ionic liquid technology, applied in chemical instruments and methods, catalytic reactions, chemical/physical processes, etc., can solve the problems of further improvement of catalytic activity and harsh catalytic reaction conditions, and achieve excellent universality and The effect of recycling performance, avoiding secondary emission problems, and good prospects for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

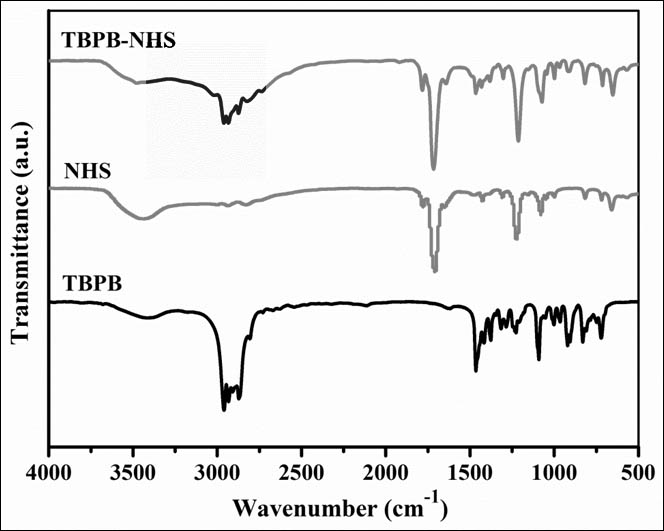

[0024] The preparation of embodiment 1 quaternary phosphonium type deep eutectic ionic liquid

[0025] Benzyltriphenylphosphonium bromide (BTPC) and N-hydroxysuccinimide (NHS) were added to a single-necked flask at a molar ratio of 1:2, and heated under magnetic stirring at 50°C for 0.5 hours , prepared to obtain BTPC-NHS.

[0026] Allyltriphenylphosphonium bromide (ATPB) and N-hydroxysuccinimide (NHS) were added to a single-necked flask at a molar ratio of 1:2, and heated under magnetic stirring at 50°C for 0.5 Hours, prepared to obtain ATPB-NHS.

[0027] Add methyltriphenylphosphonium bromide (MTPB) and N-hydroxysuccinimide (NHS) into single-necked flasks at a molar ratio of 1:2, and heat and magnetically stir at 50°C for 0.5 hours , prepared to obtain MTPB-NHS.

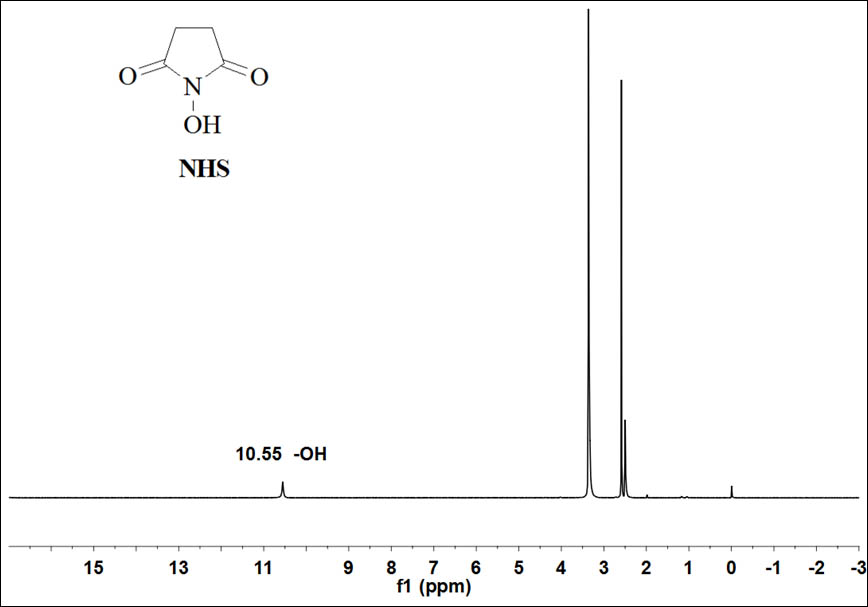

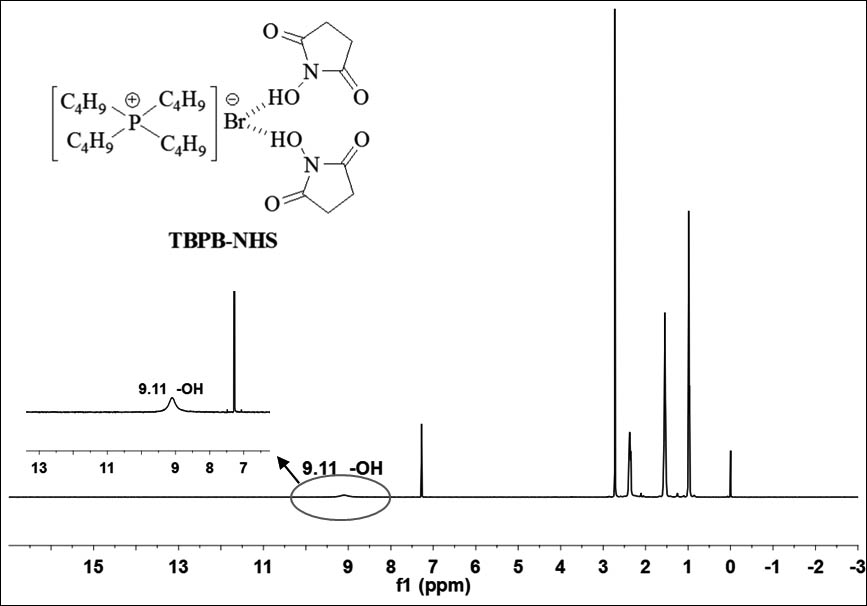

[0028] Tetrabutylphosphonium bromide (TBPB) and N-hydroxysuccinimide (NHS) were added to a single-necked flask at a molar ratio of 1:2, heated and magnetically stirred at 50°C for 0.5 hours to prepare And obtai...

Embodiment 2

[0030]Get the catalyst ATPB-NHS prepared in Example 1 and the reactant propylene oxide and add 25mL of stainless steel autoclave with polytetrafluoroethylene lining successively, wherein, propylene oxide 34.5mmol, ATPB-NHS 2.1 mmol, catalyst accounts for epoxy The molar content of propane is 6mol%; CO is slowly fed into the reactor by controlling the inlet and outlet gas valves 2 Gas to get rid of the residual air inside; after that, close the reactor and heat the reactor oil bath to 60°C, and introduce CO 2 The gas pressure was kept constant to 1.0MPa, and the reaction was continued for 2 hours; after the reaction, the reaction kettle was cooled to room temperature in an ice-water bath, and the product was quantitatively analyzed by gas chromatography. The yield of propylene carbonate was 96%, and the selectivity was ≥99%.

Embodiment 3

[0032] Get the catalyst TBPB-NHS prepared in Example 1 and the reactant epichlorohydrin and add 100mL successively to connect CO 2 The Schlenk (Schlenk) reaction flask of balloon, wherein, epichlorohydrin 10mmol, TBPB-NHS 0.8mmol, catalyst accounts for epichlorohydrin molar content and is 8mol%, decompression gets rid of the air remaining inside; Reaction flask and CO 2 Balloon connected, at a reaction temperature of 25°C, 0.1MPa CO 2 Under pressure conditions, the reaction is continued for 24 hours; after the reaction, the product is quantitatively analyzed by gas chromatography, and the corresponding product yield is 98%, and the selectivity is ≥99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com