A cement-based high-early-strength non-shrinkage grouting material

A cement-based, non-shrinking technology, applied in the field of cement-based materials, can solve the problems of unmentioned strength, limited use range, and decreased construction performance of grouting materials, and achieve excellent long-term strength and strength growth rate, with remarkable super early strength characteristics. , the effect of shortening the setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of high belite sulfoaluminate cement clinker powder:

[0030] According to the raw meal weight ratio and ingredient ratio value shown in Table 1, 1.0 ton of raw meal with a fineness of 0.08 mm and a sieve residue of less than 8% was obtained by grinding. The high belite sulfoaluminate cement clinker with a loss of 28%) was ground to obtain a specific surface area of 400 to 500 m 2 / kg of clinker powder.

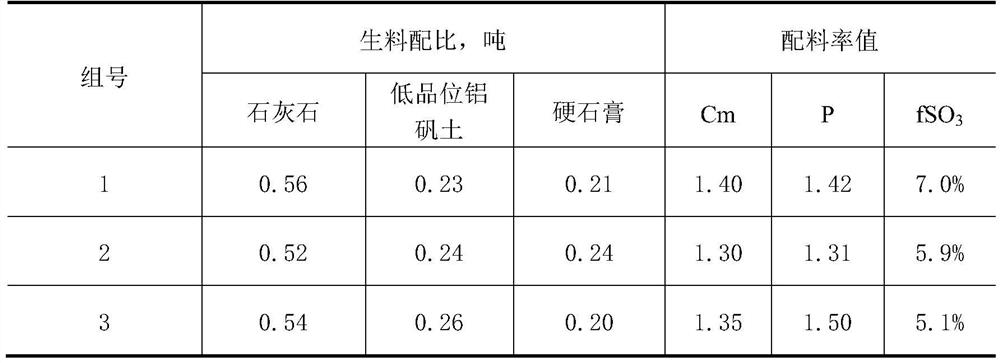

[0031] Table 1 Raw meal ratio and ingredient ratio value

[0032]

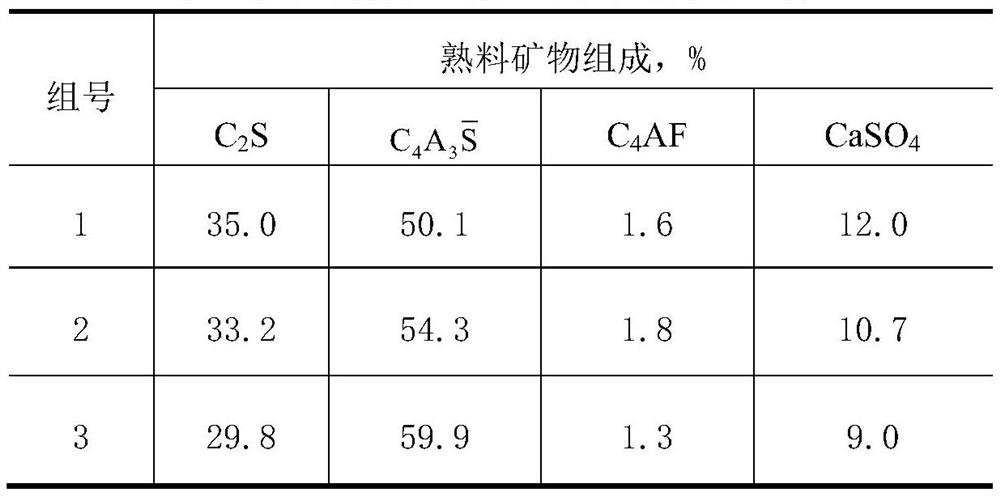

[0033] The mineral composition of the clinker is shown in Table 2.

[0034] Table 2 Mineral composition of high belite sulfoaluminate cement clinker

[0035]

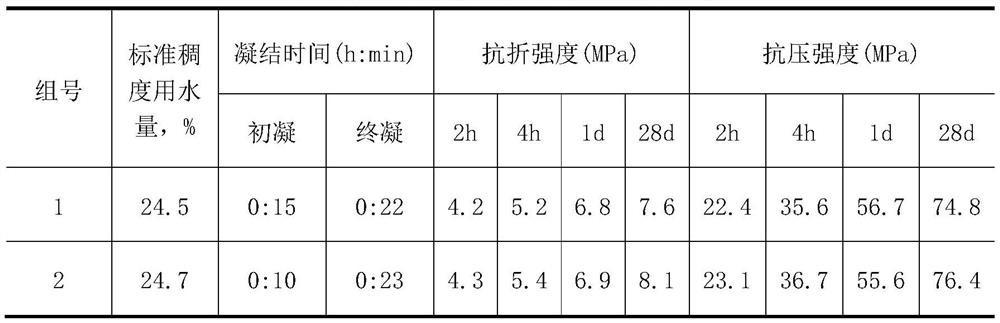

[0036] The obtained high Belitt sulfoaluminate cement clinker with high early strength properties, in accordance with the standard GB17671-1999 "Cement mortar strength test method (ISO method)" and GB / T1346-2011 "Cement standard consistency water consumption, The physical properties of high-belite sulfoaluminate cement cl...

Embodiment 2

[0043] Preparation of high belite sulfoaluminate special cementitious material:

[0044] According to the weight ratio shown in Table 4, the components were added to the dry powder mixer in turn, and the high-belite sulfoaluminate special cementitious material for high-early-strength non-shrinkage grouting was obtained after thorough and uniform mixing.

[0045] Table 4 Weight ratio of high belite sulfoaluminate special cementitious material

[0046]

[0047] Using the standard GB17671-1999 "Cement mortar strength test method (ISO method)", GB / T1346-2011 "Cement standard consistency water consumption, setting time, stability test method" and TC / T313-2009 "Expansion cement expansion rate test" Methods" The physical properties of the above three groups of high-belite sulfoaluminate special cementitious materials were measured, and the results are shown in Table 5.

[0048] Table 5 Physical properties of high belite sulfoaluminate special cementitious materials

[0049]

...

Embodiment 3

[0053] Preparation of high-early-strength non-shrinkage grouting material

[0054] In this embodiment, polycarboxylic acid dry powder is selected as the alkaline water agent, mineral oil dry powder is selected as the defoaming agent, and low-viscosity cellulose ether is selected as the cellulose ether.

[0055] Group number 1:

[0056] Weigh each raw material component according to the following weights: 1000g high belite sulfoaluminate special cementitious material; 100g heavy calcium powder; 860g quartz sand; 10g latex powder; 14g water reducing agent; 10g defoaming agent; cellulose ether 2g; citric acid 3g; lithium carbonate 1g, totaling 2000g. Pour the weighed materials into the mixer for full mixing, until the bulk density of multiple randomly selected samples does not change after measurement, and the mixture is uniform to obtain cement-based high-early-strength non-shrinkage grouting material.

[0057] Group number 2:

[0058] Weigh each raw material component accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com