Micro-foaming polypropylene material and preparation method thereof

A polypropylene material and micro-foaming technology, applied in the polymer field, can solve the problems of high cost of maleic anhydride, insufficient mixing and high cost, and achieve the effects of good mechanical properties, avoiding agglomeration and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

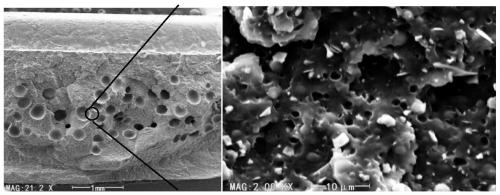

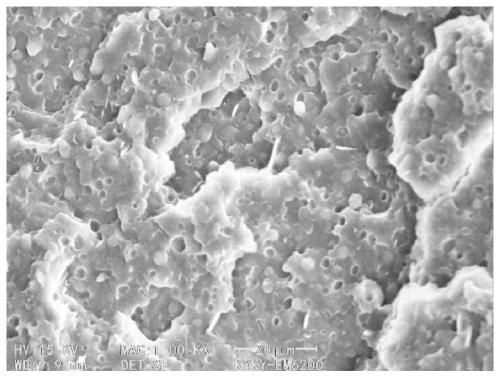

[0026] Using a high-speed impact jet mill, the talc powder with a mass percentage of 95% and the composite foaming agent with a mass percentage of 5% are compounded to obtain a foaming agent composite powder, wherein the composite foaming agent is selected from the first phase of the foaming agent Nitrogendiformamide, second-phase foaming agent sodium bicarbonate, the D50 value of the foaming agent composite powder particle size distribution is 8.5 microns. The composite powder of polypropylene resin with a melt flow rate of 2.5 and modified foaming agent is extruded and granulated at a maximum temperature of 180°C according to a mass ratio of 10:1, and injected at a maximum temperature of 230°C Molding, the product density is 0.88g / cm 3 . The surface of the prepared sample is smooth without leaving any marks, and there are microbubbles with uniform pore size, average size of 150 microns and microbubbles with a pore size of less than 10 microns in the composite microbubble st...

Embodiment 2

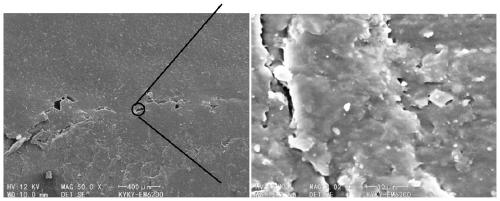

[0028] The polypropylene resin with a melt flow rate of 20 and the foaming agent composite powder in the above-mentioned Example 1 were extruded and granulated at a maximum temperature of 180° C. at a maximum temperature of 230° C. according to a mass ratio of 10:1. Injection molding is carried out at high temperature, and the product density is 0.91g / cm 3 .

Embodiment 3

[0030] The polypropylene resin with a melt flow rate of 20 and the foaming agent composite powder in the above-mentioned Example 1 were extruded and granulated at a maximum temperature of 180° C. at a maximum temperature of 230° C. according to a mass ratio of 10:1. Injection molding is carried out at high temperature, and the product density is 0.92g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com