Preparation method of organically modified hydrotalcite-based flame retardant for paper

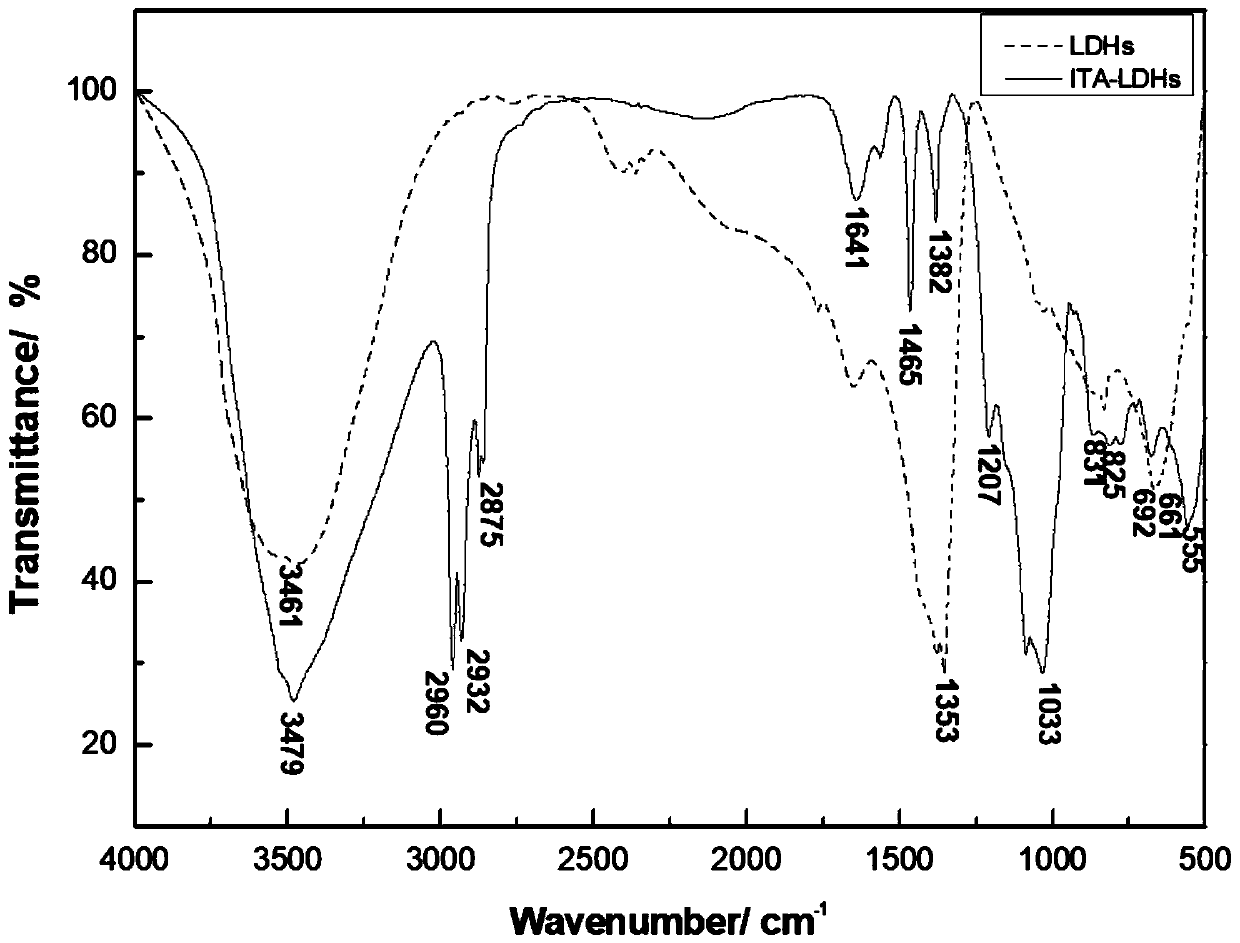

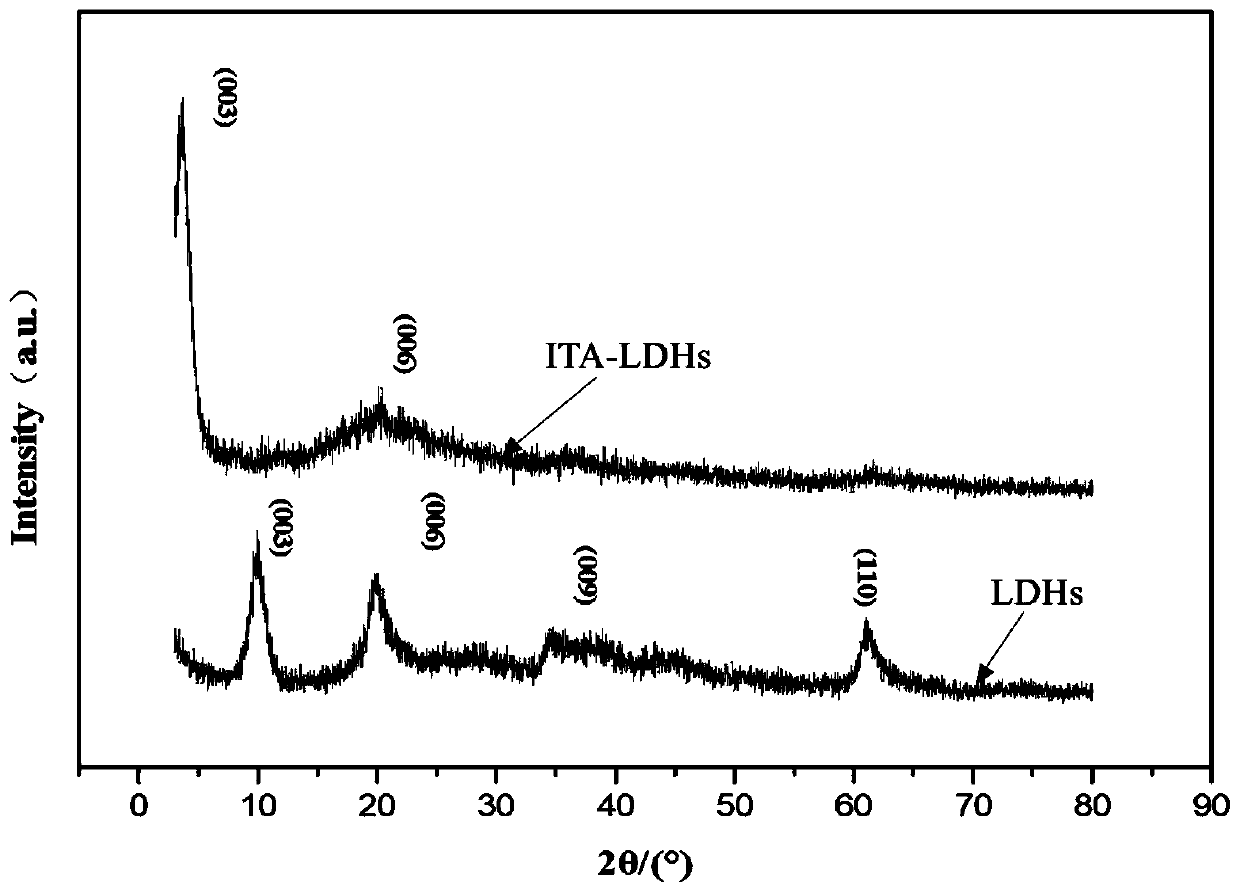

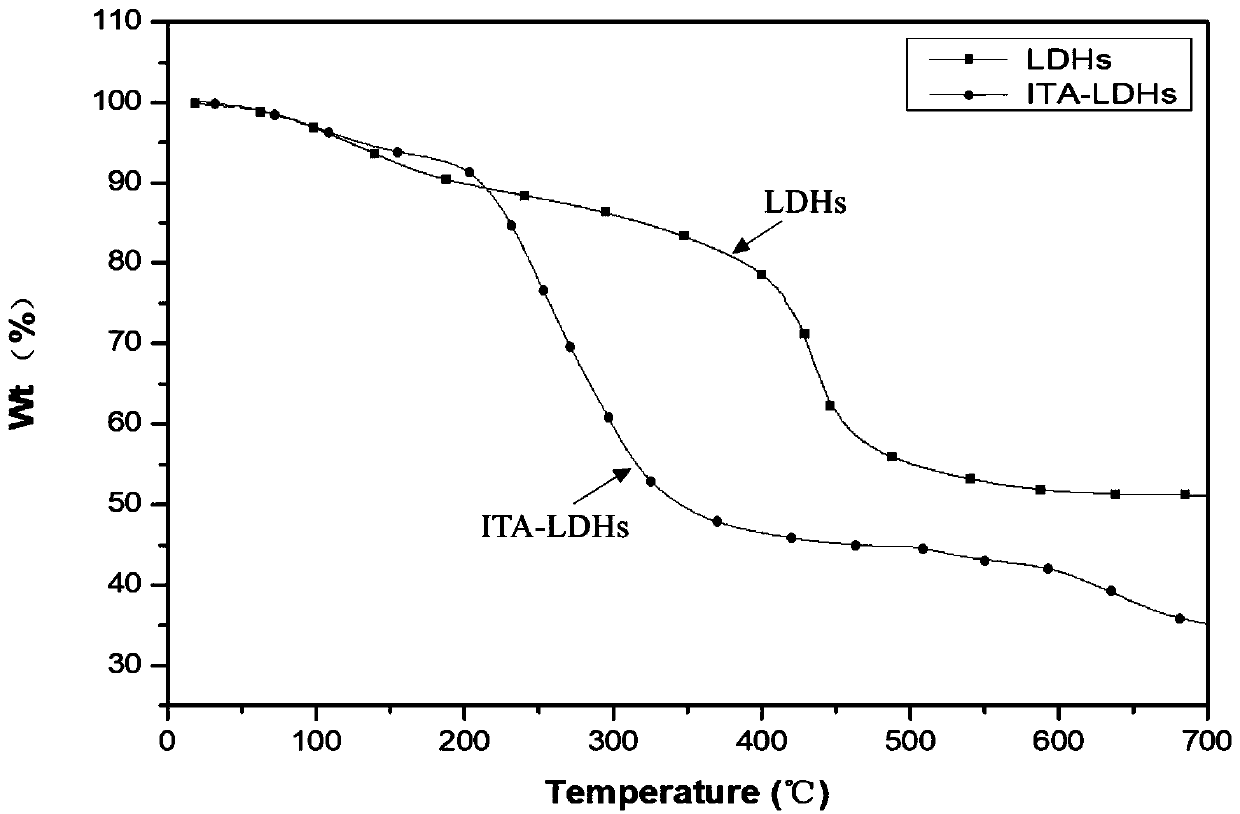

A technology for modifying water and talc. It is applied in the directions of adding paper, fire retardant and inorganic compound, etc. It can solve the problems of low retention rate, easy agglomeration of hydrotalcite, poor adsorption, etc. degree and opacity, the effect of not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the hydrotalcite-based paper flame retardant of the present invention prepares the composite modified hydrotalcite with cationic polymer intercalation and coupling agent covering through the method of ion exchange. Specifically include the following steps:

[0038] A preparation method of an organically modified hydrotalcite type paper flame retardant, comprising the following steps:

[0039] (1) Sodium hydroxide (NaOH) and sodium carbonate (NaOH) 2 CO 3 ) was dissolved in water to prepare a mixed alkali solution.

[0040] Dissolve magnesium salt and aluminum salt in water to prepare mixed salt solution. Magnesium salt is one or more of magnesium nitrate, magnesium chloride, magnesium sulfate, aluminum salt is one or more of aluminum nitrate, aluminum chloride, aluminum sulfate, and Mg 2+ with Al 3+ The molar ratio is 1:1 or 2:1 or 3:1.

[0041] (2) Slowly add the mixed alkali solution and the mixed salt solution prepared in step (1) into...

Embodiment 1

[0046] Double titration synthesis method: molar ratio Mg 2+ :Al 3+ =2:1 Weigh 12.8g Mg(NO) 2 ·6H 2 O and 9.3g Al(NO) 3 9H 2 Dissolve O together in 100.0ml deionized water to prepare a mixed salt solution, mix well and pour the solution into a constant pressure funnel; weigh 8.1g NaOH and 1.5g NaOH 2 CO 3Dissolve in 100.0ml deionized water to prepare a mixed alkali solution, mix well and pour the solution into a constant pressure funnel; then slowly add the mixed salt solution and the mixed alkali solution dropwise into the reaction vessel at room temperature, and keep The pH value of the solution in the reaction vessel is about 10-11; after the dropwise addition, stir for 1.0h to prepare Mg-Al-CO 3 - LDHs precursors. Then heat up to 80°C, add 2.0ml of 10.0% polyvinylamine solution, stir and react at constant temperature for 1.0h, then add 2.0g of titanate coupling agent NDZ-201 dissolved in 50.0ml of ethanol and stir at 80°C for 2.0 h; stop stirring, keep warm at 80°C ...

Embodiment 2

[0054] Single titration synthesis method: Weigh 8.0g NaOH and 1.5g NaOH 2 CO 3 Dissolve in 200.0ml deionized water to prepare a mixed alkali solution, mix well and pour the solution into a 500.0ml three-necked flask; molar ratio Mg 2+ :Al 3+ = 2:1 Weigh 19.2gMg(NO) 2 ·6H 2 O and 9.3g Al(NO) 3 9H 2 Dissolve O in 100.0ml deionized water to prepare a mixed salt solution, mix well and pour the solution into a constant pressure funnel; then slowly add the mixed salt solution to the mixed alkali solution at room temperature, and keep the pH value of the solution during the dropping process At about 10-11; After the dropwise addition, stir for 1.0h, then raise the temperature to 80°C, add 2.0ml of 10.0% polyethyleneimine solution, stir at constant temperature for 1.0h, then add 2.0g of silane dissolved in 50.0ml of ethanol The coupling agent KH-550 was stirred and reacted for 2.0 hours; the stirring was stopped, and the temperature was kept for 18.0 hours; the slurry obtained a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com