Preparation method of strong corrosion-resistant magnesium alloy biological composite material

A composite material and magnesium alloy technology, which is applied in the field of preparation of strong corrosion-resistant magnesium alloy bio-composite materials, can solve problems such as hemolysis and magnesium alloy failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

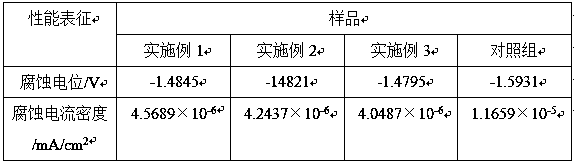

Examples

Embodiment 1

[0025] In parts by weight, weigh 45 parts of deionized water, 10 parts of sodium phosphate, 6 parts of 10% sodium hydroxide solution and 10 parts of 10% sodium bicarbonate solution in a three-necked flask, stir and mix. Stand at room temperature for 6 hours to obtain an alkali washing solution; weigh 45 parts of deionized water, 3 parts of chromium oxide and 3 parts of 15% nitric acid by mass fraction respectively in a three-necked flask, stir and mix and place Stand at room temperature for 6 hours to obtain pickling solution; weigh 45 parts of deionized water, 1 part of silver nitrate, and 1 part of 1% nitric acid in Erlenmeyer flasks by weight, stir and mix to obtain etching solution. solution; take the magnesium alloy substrate and soak the magnesium alloy substrate in the alkali washing solution according to the mass ratio of 1:15, stir and mix and place it under 200W for ultrasonic cleaning for 15min, take out the magnesium alloy substrate after washing and then press the ...

Embodiment 2

[0027] In parts by weight, weigh 48 parts of deionized water, 12 parts of sodium phosphate, 7 parts of 10% sodium hydroxide solution and 12 parts of 10% sodium bicarbonate solution in a three-necked flask, stir and mix. Stand at room temperature for 7 hours to obtain an alkali washing solution; weigh 47 parts of deionized water, 4 parts of chromium oxide and 4 parts of 15% nitric acid by mass fraction respectively in a three-necked flask, stir and mix Stand at room temperature for 7 hours to obtain pickling solution; weigh 47 parts of deionized water, 2 parts of silver nitrate, and 2 parts of 1% nitric acid in Erlenmeyer flasks by weight, stir and mix to obtain etching solution. solution; take the magnesium alloy substrate and soak the magnesium alloy substrate in the alkaline washing solution according to the mass ratio of 1:15, stir and mix and place it under 200-300W for ultrasonic cleaning for 17min, take out the magnesium alloy substrate after washing and then wash it acco...

Embodiment 3

[0029] In parts by weight, weigh 50 parts of deionized water, 15 parts of sodium phosphate, 8 parts of 10% sodium hydroxide solution and 15 parts of 10% sodium bicarbonate solution in a three-necked flask, stir and mix. Stand at room temperature for 8 hours to obtain an alkali washing solution; weigh 50 parts of deionized water, 5 parts of chromium oxide and 5 parts of 15% nitric acid by mass fraction respectively in a three-necked flask, stir and mix and place Stand still at room temperature for 8 hours to obtain pickling solution; weigh 50 parts of deionized water, 2 parts of silver nitrate, and 2 parts of 1% nitric acid in an Erlenmeyer flask, stir and mix to obtain an etching solution. solution; take the magnesium alloy substrate and soak the magnesium alloy substrate in the alkali washing solution according to the mass ratio of 1:15, stir and mix and place it under 300W for ultrasonic cleaning for 20min, take out the magnesium alloy substrate after washing and then press t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com