Method of recovering phosphate radical and sulfate radical from iron phosphate production wastewater

A technology for the production of wastewater and phosphate radicals, which is applied to chemical instruments and methods, phosphate, phosphorus oxyacids, etc., can solve problems such as high operating costs, high production costs, and complicated processes, and achieve reasonable process routes and process conditions. Solve the effect that the purity is difficult to control and the technical conception is ingenious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

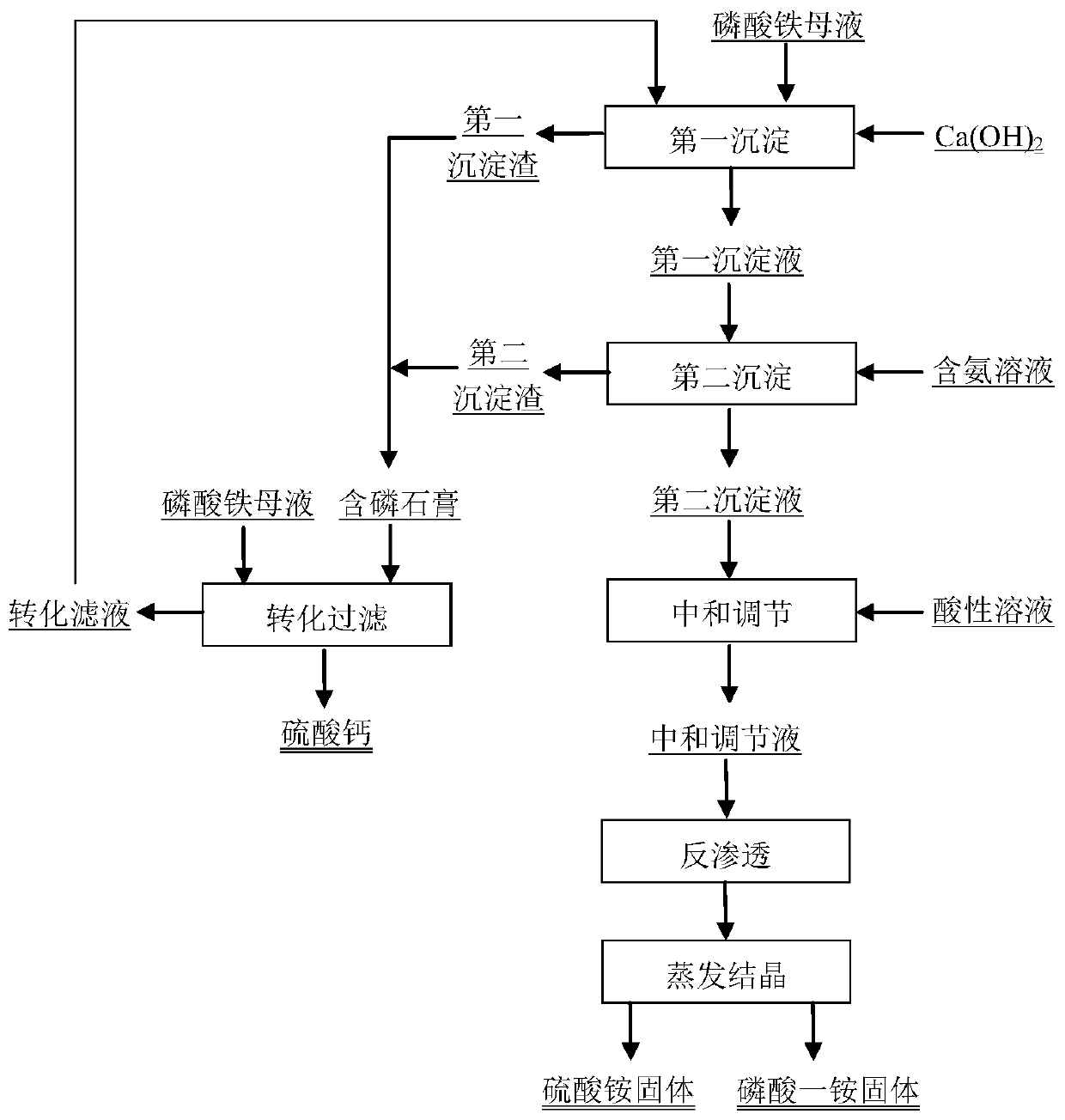

[0044] A kind of method of reclaiming phosphate radical and sulfate radical from ferric phosphate production waste water of the present invention, its technological process schematic diagram is as figure 2 shown, including the following steps:

[0045] (1) Add Ca(OH) to 50L ferric phosphate mother liquor (phosphate concentration is 15.0g / L, sulfate concentration is 48.0g / L, ammonia nitrogen concentration is 7.0g / L, pH value is 1.1) 2 Carrying out the first precipitation reaction, controlling the pH value of the first precipitation reaction to be 5, stirring and mixing for 2 hours, and then filtering to obtain the first precipitation residue and the first precipitation liquid;

[0046] (2) Add ammoniacal solution (10% ammonia solution) to the first precipitation solution after step (1) to carry out the second precipitation reaction, control the pH value of the second precipitation reaction to be 10, stir and mix for 2h and then filter to obtain the second precipitation reactio...

Embodiment 2

[0053] A kind of method of reclaiming phosphate radical and sulfate radical from ferric phosphate production waste water of the present invention adopts the steps similar to the method of embodiment 1, and the difference with embodiment 1 is: phosphate radical concentration is 5.4g / in ferric phosphate mother liquor L, the concentration of sulfate radicals is 25.5g / L, the concentration of ammonia nitrogen is 5.2g / L, the pH value of the ferric phosphate mother liquor is 1.2; the pH value of the first precipitation reaction is controlled to be 4, and the stirring and mixing time is 0.5h; the second precipitation reaction The pH value of the solution is 9, and the stirring and mixing time is 0.5 h; in step (5), the second precipitation solution obtained is mixed with sulfuric acid with a mass concentration of 4%, to obtain a neutralization adjustment solution with a pH of 4.

[0054] After testing, the concentration of phosphate in the second precipitation solution was 5.4g / L, and...

Embodiment 3

[0056] A kind of method of reclaiming phosphate radical and sulfate radical from ferric phosphate production waste water of the present invention adopts the steps similar to the method of embodiment 1, and the difference with embodiment 1 is: phosphate radical concentration is 9.5g / L, the sulfate radical concentration is 45.6g / L, the ammonia nitrogen concentration is 6.2g / L, the pH value of iron phosphate mother liquor is 0.9; 2 The clear solution after the precipitation is mixed to obtain the pH value of the ammonia solution is 11.5, the ammonia solution is added to the first precipitation solution, and stirred for 1 hour. Phosphorus-containing gypsum was mixed with 50 L of ferric phosphate mother liquor and stirred for 0.5 h, and the pH value of the mixed liquor was controlled to be 1.5 during the transformation process to obtain transformation filtrate and calcium sulfate.

[0057] After testing, the concentration of phosphate in the second precipitation solution was 9.5g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com