Catalyst for producing hydrocarbon fuels by hydrodeoxygenation of animal and vegetable oils and its preparation method

A technology for producing hydrocarbons from animal and vegetable oils and deoxygenation, which is applied in the direction of physical/chemical process catalysts, fatty acid hydrogenation, molecular sieve catalysts, etc. It can solve the problems of high hydrogen consumption and energy consumption, complex processes, and large investment in production equipment, etc. Mechanical strength, increased specific surface area, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

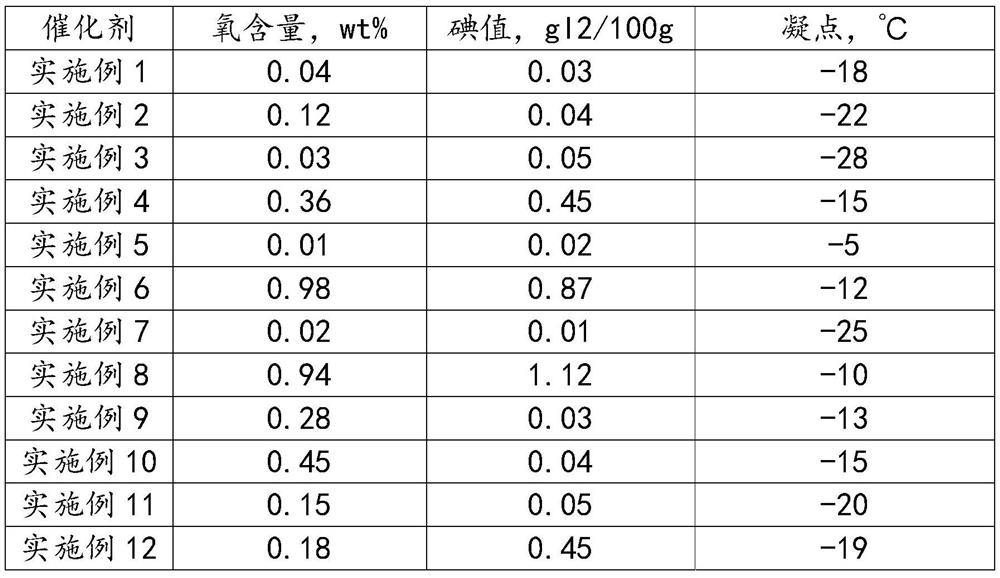

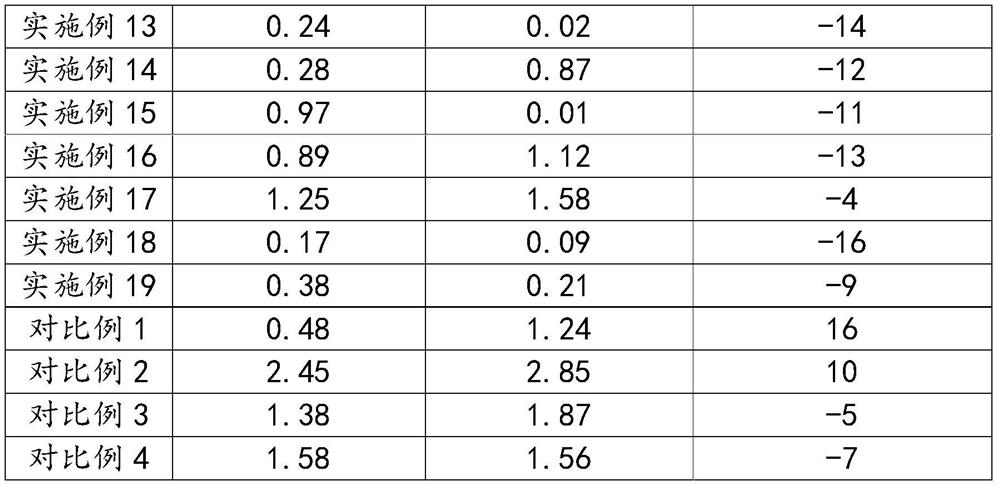

Examples

preparation example Construction

[0039] The present invention also relates to a method for preparing the above-mentioned catalyst for hydrogenation and deoxygenation of animal and vegetable oils to produce hydrocarbon fuels, comprising the following steps: loading active components on a composite carrier prepared by perovskite and acidic carrier.

[0040] The preparation of the composite carrier specifically includes the following steps: adding a binder to the perovskite and the acidic carrier to form a mixture, then adding a peptizer and water to the mixture, kneading and molding after mixing, and then drying and roasting the formed product , to obtain a composite carrier.

[0041] The perovskite is commercially available or prepared according to the following method: dissolve soluble rare earth metal salts, soluble alkaline earth metal salts, and soluble transition metal salts in water to form a solution with a concentration of 0.25-2.5mol / L, and then add complex mixture, and finally put the solution added ...

Embodiment 1

[0047] 1) Preparation of perovskite

[0048] Lanthanum nitrate, calcium nitrate, iron nitrate, and manganese nitrate are formulated into a precursor aqueous solution A of perovskite-type active components, wherein the molar ratio of metal ions La: Ca: Fe: Mn is 9:1:1:9 , the total molar concentration of metal ions is 1.0mol / L; add a certain amount of citric acid to solution A, the molar ratio of citric acid to La, Ca, Fe, Mn metals is 1.0, stir and fully dissolve to obtain solution B ; Place solution B in an oven and dry at 100°C for 24 hours to evaporate excess water to obtain gel A; place gel A in a muffle furnace to roast at 800°C for 3 hours to obtain perovskite La 0.9 Ca 0.1 Fe 0.1 mn 0.9 o 3 .

[0049] 2) Forming of composite carrier

[0050] 150gLa 0.9 Ca 0.1 Fe 0.1 mn 0.9 o 3 , 100g γ-Al 2 o 3 , 50gZSM-5, 20g turmeric powder, and 30g pseudoboehmite are fully mixed; add 100g of deionized water and 10g of acetic acid to the dry material of the mixture, fully...

Embodiment 2

[0053] 1) Preparation of perovskite

[0054] Lanthanum nitrate, calcium nitrate, iron nitrate, and manganese nitrate are formulated into a precursor aqueous solution A of perovskite-type active components, wherein the molar ratio of metal ions La: Ca: Fe: Mn is 5:5:5:5 , the total molar concentration of metal ions is 2.0mol / L; add a certain amount of citric acid to solution A, the molar ratio of citric acid to La, Ca, Fe, Mn metals is 0.5, stir and fully dissolve to obtain solution B; Solution B was dried in an oven at 120°C for 4 hours, and excess water was evaporated to obtain gel A; gel A was calcined in a muffle furnace at 700°C for 6 hours to obtain perovskite La 0.5 Ca 0.5 Fe 0.5 mn 0.5 o 3 .

[0055] 2) Forming of composite carrier

[0056] 100gLa 0.5 Ca 0.5 Fe 0.5 mn 0.5 o 3 , 100g amorphous silica-alumina, 100gZSM-22, 10g gum, 15g pseudo-boehmite are fully mixed; add deionized water 90g, oxalic acid 5g in the dry material of the mixture, fully knead, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com