Polyimide foam composite material, and preparation method and application thereof

A technology of polyimide and composite materials, applied in the direction of chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problem of tensile strength and poor scratch resistance, shear resistance The comprehensive properties of imide foam materials and the high glass transition temperature of polyimide foam achieve the effects of reducing the amount of smoke in sudden accidents, easy promotion, and excellent thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

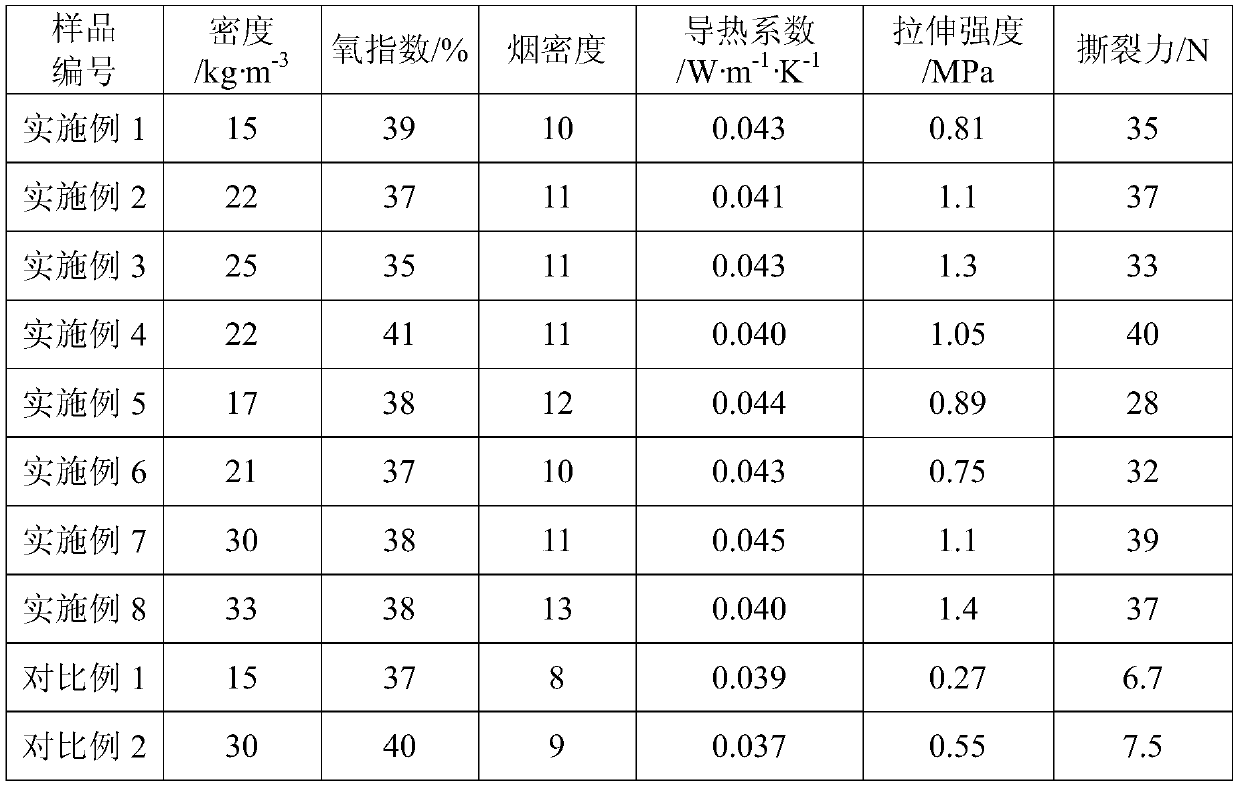

Examples

Embodiment 1

[0038] The present embodiment provides a kind of preparation method of polyimide foam composite material, wherein, this method comprises the following steps:

[0039] a. Add 32.2g of dried 3,3',4,4'-benzophenone tetraacid dianhydride to a mixed solvent containing 43g of tetrahydrofuran and 9.6g of methanol, raise the temperature to 60°C, keep stirring for 6h and then cool down After reaching room temperature, add 20g of 4,4'-diaminodiphenyl ether (4,4'-ODA), heat up to 60°C and mix for 2 hours, then add 2.0g of AK 8805, and discharge to obtain a precursor solution;

[0040]b. Treat the precursor solution in an oven at 90°C for 30 minutes, then pulverize the dried product and place it in an oven at 120°C for foaming. After 30 minutes, heat up to 200°C for preliminary imidization for 20 minutes;

[0041] c. Cut the foam obtained above to obtain a foam material with a thickness of 3 cm, then apply glass fiber cloth on the surface of the foam material, set the temperature of the h...

Embodiment 2

[0044] The present embodiment provides a kind of preparation method of polyimide foam composite material, wherein, this method comprises the following steps:

[0045] a. Add 32.2g of dried 3,3',4,4'-benzophenone tetraacid dianhydride to a mixed solvent containing 64g of tetrahydrofuran and 9.6g of methanol, raise the temperature to 60°C, and continue stirring for 6h Cool down to room temperature, add 41g of 2,2-bis[4-(4-aminophenoxy)phenyl]propane (BAPP), heat up to 60°C and mix for 2 hours, then add 3g of AK 8805, and discharge to obtain a precursor solution ;

[0046] b. Treat the precursor solution in an oven at 80°C for 60 minutes, then pulverize the dried product and place it in an oven at 140°C for foaming and imidization for 30 minutes;

[0047] c. Cut the foam obtained above to obtain a foam material with a thickness of 1.5 cm, then apply glass fiber cloth on the surface of the foam material, set the temperature of the hot plate of the flat vulcanizer to 290 ° C, and ...

Embodiment 3

[0050] The present embodiment provides a kind of preparation method of polyimide foam composite material, wherein, this method comprises the following steps:

[0051] a. Add 21.8g of dried 1,2,4,5-pyromellitic dianhydride into a mixed solvent containing 64g of tetrahydrofuran and 9.6g of methanol, raise the temperature to 60°C, keep stirring for 6h, then cool down to room temperature, Add 41g of 2,2-bis[4-(4-aminophenoxy)phenyl]propane (BAPP), heat up to 60°C and mix for 2 hours, then add 3g of AK 8805, and discharge to obtain a precursor solution;

[0052] b. Treat the precursor solution in a 90°C oven for 15 minutes, then crush the dried product and place it in a 120°C oven for foaming for 30 minutes, then heat up to a 180°C oven for preliminary imidization , the duration is 45min;

[0053] c. Cut the foam obtained above to obtain a foam material with a thickness of 1.5 cm, and then apply glass fiber cloth on the surface of the foam material. 1.3cm, the hot pressing time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com