an adsorbed co 2 Preparation method of porous carbon material doped with nitrogen

A technology of nitrogen-doped porous carbon and quaternary ammonium base, which is applied in the field of porous carbon materials, can solve the problems of less active functional groups in the specific surface area of carbon materials, time-consuming and laborious regeneration of polyurethane, and poor compatibility of carbon structures, so as to increase CO2 adsorption capacity , Adsorption selectivity and cycle regeneration performance are excellent, and the effect of high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

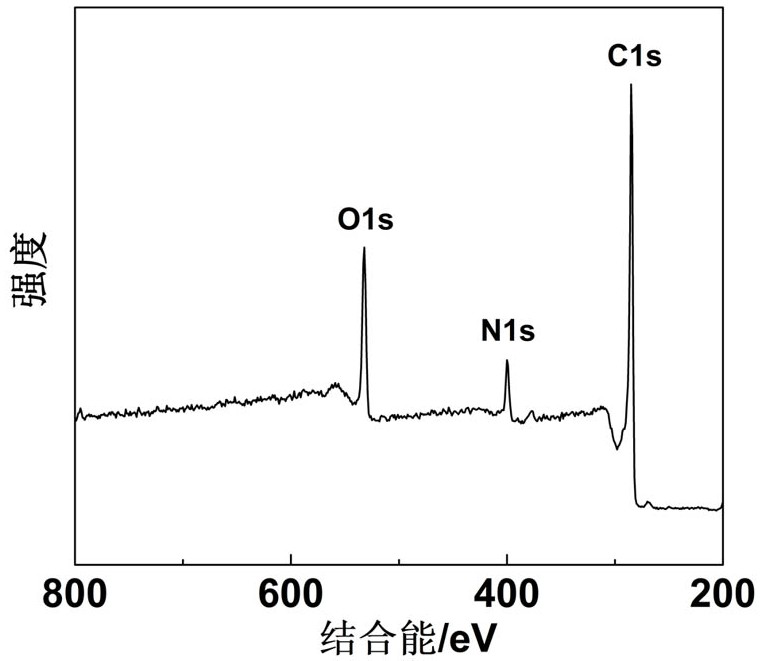

[0034] The discarded polyurethane foam was broken into 2 mm*2 mm*2 mm particles, and 10 g was immersed in 15 g of tetramethylammonium hydroxide solution with a mass fraction of 25% under the condition of vacuum magnetic stirring for 2 h , and then dried in a vacuum oven at 55 °C for 30 h, cooled and placed in a tube furnace with continuous flow of N at a rate of 80 ml / min. 2 And the temperature was raised to 500 °C at a rate of 5 °C / min and kept for 2.5 h for chemical activation and nitrogen fixation; followed by direct CO 2 Physical activation, that is, the rate of 5 ℃ / min is raised to 900 ℃ and the N 2 Change to CO 2 , to create ultra-micropores with a pore size of less than 1 nm, through which CO 2 The rate is 35ml / min and kept for 2 hours, switch to N immediately after activation 2 , when it is protected down to room temperature, the polyurethane foam-based nitrogen-doped porous carbon material is obtained.

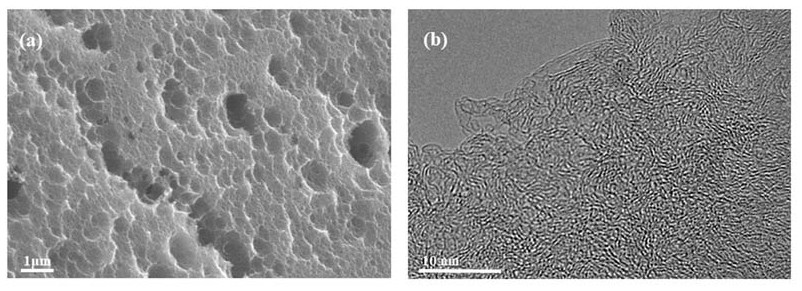

[0035] Depend on figure 1 a It can be seen that the surface...

Embodiment 2

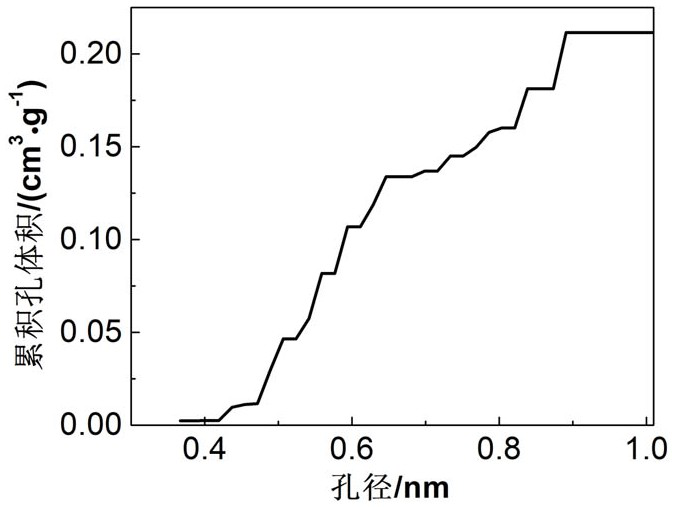

[0038] The discarded polyurethane foam was broken into 3 mm*3 mm*3 mm particles, and 10 g was immersed in 25 g of tetraethylammonium hydroxide solution with a mass fraction of 25% under the condition of vacuum magnetic stirring for 4 h , and then dried in a vacuum oven at 65 °C for 25 h, cooled and placed in a tube furnace to continuously feed N at a rate of 100 ml / min. 2 And the temperature was raised to 600 °C at a rate of 8 °C / min and kept for 2 h for chemical activation and nitrogen fixation; followed by direct CO 2 Physical activation, i.e. rising to 800 °C at a rate of 5 °C / min and N 2 Change to CO 2 , to create ultra-micropores with a pore size of less than 1 nm, through which CO 2 The rate is 25ml / min and kept for 2 hours, switch to N immediately after activation 2 , when it is protected down to room temperature, the polyurethane foam-based nitrogen-doped porous carbon material is obtained. Its BET specific surface area is 1247 m 2 / g, the pore volume of ultramicr...

Embodiment 3

[0041] The discarded polyurethane foam was broken into 4 mm*4 mm*4 mm particles, and 10 g was immersed in 8 g of tetrapropylammonium hydroxide solution with a mass fraction of 25% under the condition of vacuum magnetic stirring for 6 h , then dried in a vacuum oven at 75 °C for 20 h, cooled and placed in a tube furnace, and continuously fed N at a rate of 90 ml / min. 2 And the temperature was raised to 500 °C at a rate of 5 °C / min and kept for 2.5 h for chemical activation and nitrogen fixation; followed by direct CO 2 Physical activation, that is, the rate of 5 ℃ / min is raised to 1000 ℃ and the N 2 Change to CO 2 , to create ultra-micropores with a pore size of less than 1 nm, through which CO 2 The rate is 35ml / min and maintained for 1.5 h, switch to N immediately after activation 2 , when it is protected down to room temperature, the polyurethane foam-based nitrogen-doped porous carbon material is obtained. Its BET specific surface area is 1510 m 2 / g, the pore volume o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com