Hydroxylation black phosphorus quantum dot water-based solution preparation method and application

A technology for hydroxylation of black phosphorus and quantum dots, which is used in the preparation of phosphorus, medical preparations containing active ingredients, phosphorus, etc., can solve the problem that the stability of black phosphorus quantum dots needs to be improved, restrict the development and application of black phosphorus quantum dots, Phosphorus quantum dots are prone to degradation and other problems, achieving the effect of easy promotion, low friction coefficient, and easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Prepare the hydroxylated black phosphorus quantum dot water-based solution according to the following steps:

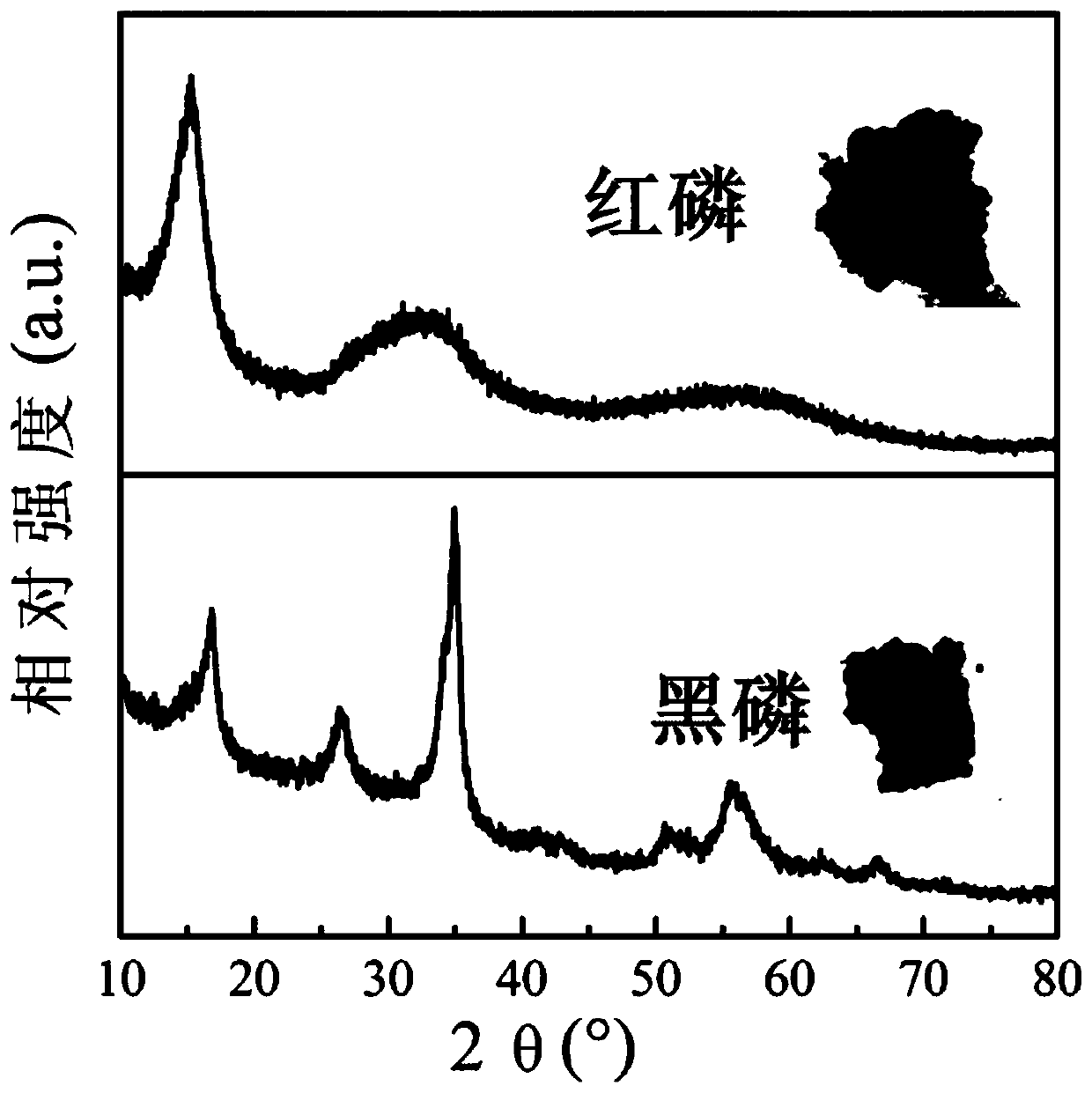

[0040] (1) Weigh 2 grams of red phosphorus powder with a purity of 99% and an average particle size of 7 μm (the price is about 1.8 yuan / g) and put it into a high-energy ball mill tank for ball milling. The ball-to-material ratio is 30:1, and nitrogen is introduced into the ball mill tank Finally, seal it, and then start ball milling, the ball milling speed is 800rpm, the ball mill pauses for 20 minutes every 1 hour of ball milling, and the ball milling time is 24 hours; superfine black phosphorus powder is obtained.

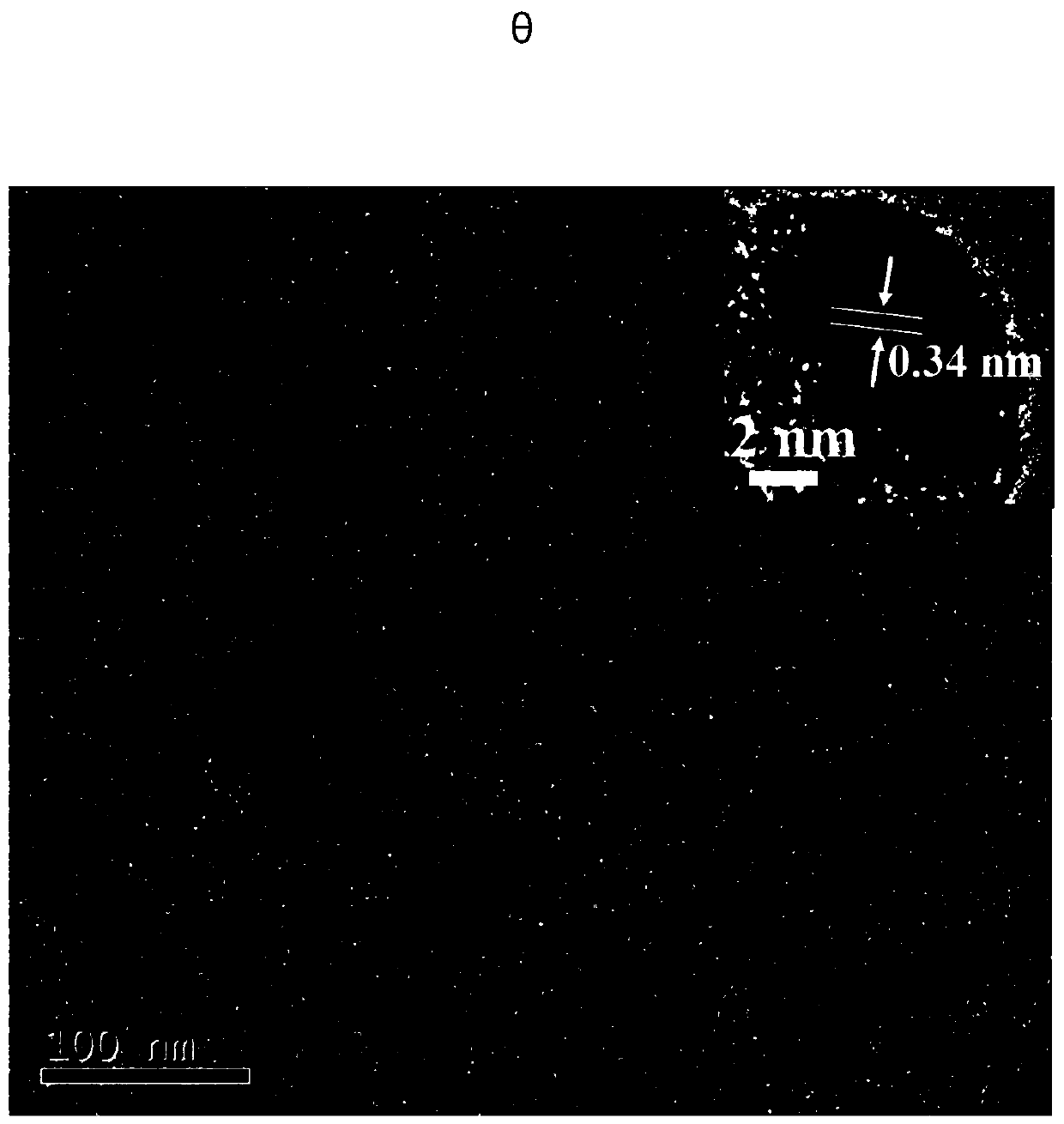

[0041] (2) After the ball mill finishes, open the ball mill tank in a glove box with nitrogen, add 30g of absolute ethanol, seal it after feeding nitrogen in the ball mill tank, then put it into the ball mill, start the second stage ball mill, the ball mill speed is 600rpm, ball milling time is 6h; in the process of high-speed ball milling, ethan...

Embodiment 2

[0050] Prepare the hydroxylated black phosphorus quantum dot water-based solution according to the following steps:

[0051] (1) Weigh 2 grams of red phosphorus powder with a purity of 99% and an average particle size of 7 μm (the price is about 1.8 yuan / g) and put it into a high-energy ball mill tank for ball milling. The ball-to-material ratio is 30:1, and nitrogen is introduced into the ball mill tank Then seal it, and then start ball milling, the ball milling speed is 800rpm, the ball mill pauses for 20min every 1h of ball milling, and the ball milling time is 30h; superfine black phosphorus powder is obtained.

[0052] (2) After the ball mill is finished, open the ball mill tank in a glove box with nitrogen gas, add 30g of ethylene glycol and ethanol with a mass ratio of 1:1 mixed solution, pass nitrogen into the ball mill tank and seal it, then put it into the ball mill , start the second stage of ball milling, the ball milling speed is 800rpm, and the ball milling time ...

Embodiment 3

[0058] Hydroxylated black phosphorus quantum dots can also be prepared by using commercially available black phosphorus blocks and black phosphorus crystal powders. Specifically, the aqueous solution of hydroxylated black phosphorus quantum dots can be prepared according to the following steps:

[0059] (1) Take 1g of commercially available black phosphorus crystal powder, put it into a high-energy ball mill jar for ball milling, and then seal it after feeding nitrogen into the ball mill jar, then start ball milling, the ball milling speed is 200rpm, and ball mill for 2h to obtain ultrafine black phosphorus powder .

[0060] (2) After the first stage of ball milling, open the ball milling jar in a glove box with nitrogen, add 30g of absolute ethanol, seal it after feeding nitrogen into the ball milling jar, then put it into the ball mill, and start the second stage of ball milling, The ball milling speed is 600rpm, and the ball milling time is 6h; during the high-speed ball mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com