Preparing method of non-woven fabric with functions of heat accumulation, temperature adjusting and bacterial resistance

A non-woven fabric, heat storage and temperature regulation technology, applied in the field of medical textile materials, can solve the problems of the decline of the antibacterial performance of the non-woven fabric, the loss of antibacterial activity, and the limited movement of small molecules, and achieve high market application value and phase transition. The effect of high latent heat and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

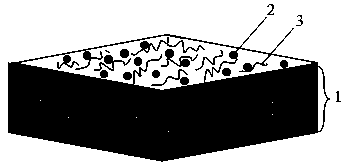

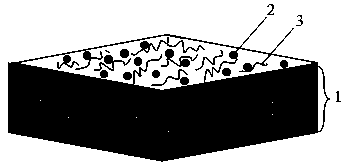

Image

Examples

Embodiment 1

[0031] A method for preparing a nonwoven fabric with heat storage, temperature adjustment and antibacterial functions, the steps are as follows:

[0032] Firstly, n-dodecyl alcohol phase change microcapsules were prepared

[0033] Slowly add 5 parts of n-dodecyl alcohol, 0.15 parts of sodium lauryl sulfate and 0.25 parts of pentaerythritol tetraacrylate into 100ml of water, raise the temperature to 50°C, stir at 1000 rpm for 10 min, and add 1 part of formaldehyde after emulsification is complete methyl acrylate and 0.075 parts of azobisisobutyronitrile, stirred for 20 min, then raised to 80°C and stirred for 5 h, the reaction product was filtered at room temperature, washed 2-3 times with absolute ethanol, and dried in vacuum for 24 h Obtain white n-dodecyl alcohol phase change microcapsules.

[0034] Then prepare the coating finishing solution

[0035] After mixing 20 parts of water-based polyurethane, 5 parts of fatty alcohol polyoxyethylene ether, 10 parts of n-dodecyl al...

Embodiment 2

[0038] A method for preparing a nonwoven fabric with heat storage, temperature adjustment and antibacterial functions, the steps are as follows:

[0039] Firstly, n-dodecyl alcohol phase change microcapsules were prepared

[0040] Slowly add 2 parts of n-dodecyl alcohol, 0.15 parts of styrene-maleic anhydride copolymer sodium salt and 0.25 parts of pentaerythritol triacrylate into 100 ml of water, raise the temperature to 50 ° C, stir at 1000 rpm for 10 min, and wait until the emulsification is complete Add 1 part of methyl methacrylate and 0.075 parts of azobisisobutyronitrile, stir for 30 min, then raise the temperature to 85°C and stir for 5 h, the reaction product is suction filtered at room temperature, washed with absolute ethanol 2-3 times, vacuum After drying for 24 h, white n-dodecyl alcohol phase change microcapsules were obtained.

[0041] Then prepare the coating finishing solution

[0042]After mixing 30 parts of water-based polyurethane, 2 parts of fatty alcoho...

Embodiment 3

[0045] A method for preparing a nonwoven fabric with heat storage, temperature adjustment and antibacterial functions, the steps are as follows:

[0046] Firstly, n-dodecyl alcohol phase change microcapsules were prepared

[0047] Slowly add 1 part of n-dodecyl alcohol, 0.2 part of styrene-maleic anhydride copolymer sodium salt and 0.25 part of pentaerythritol triacrylate into 100 ml of water, raise the temperature to 50°C, stir at 1000 rpm for 15 min, and wait until the emulsification is complete Add 1 part of methyl methacrylate and 0.1 part of azobisisobutyronitrile, stir for 30 min, then raise the temperature to 90°C and stir for 7 h, the reaction product is suction filtered at room temperature, washed with absolute ethanol 2-3 times, vacuum After drying for 24 h, white n-dodecyl alcohol phase change microcapsules were obtained.

[0048] Then prepare the coating finishing solution

[0049] After mixing 30 parts of water-based polyurethane, 1 part of sodium lauryl sulfate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com