Loudspeaker coating glue and coating process thereof

A glue and coating technology, applied in the direction of adhesives, shellac adhesives, adhesive types, etc., can solve the problems of poor coating quality and unoptimized glue coating process, and achieve excellent acid resistance and low flow Sexuality, the effect of ensuring coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

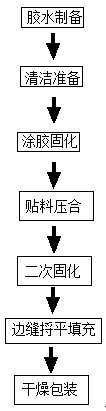

[0023] Put 30 parts of polyvinyl alcohol in a round bottom flask, add 5 parts of superfine barium sulfate, 3 parts of preservative, 2 parts of dispersant, 6 parts of butyl rubber and 100 parts of water, heat and stir, and keep the temperature at 90°C Until the polyvinyl alcohol is completely dissolved, cool down to 70°C, add 36% hydrochloric acid dropwise and stir for 20 minutes to adjust the pH value, then add 20 parts of formaldehyde and continue stirring at constant temperature for 45 minutes, then add 2 parts of urea for amination treatment, and then add Continue to stir 5 parts of tributyl phosphate for 5 minutes, finally add PH to neutral, cool down to room temperature and discharge, use cotton yarn and organic solvent to remove oil and impurities on the surface to be pasted, etc. For oil and impurities on the attached surface, cut a suitable small hole on the tip of the rubber tube, put it into a sizing gun, drip the prepared glue to the center line of the attached surfa...

Embodiment 2

[0026] Put 40 parts of polyvinyl alcohol in a round bottom flask, add 6 parts of superfine barium sulfate, 4 parts of preservative, 3 parts of dispersant, 7 parts of butyl rubber and 120 parts of water, heat and stir, and keep the temperature at 92 °C Until the polyvinyl alcohol is completely dissolved, cool down to 75°C, add 37% hydrochloric acid dropwise and stir for 25 minutes to adjust the pH value, then add 30 parts of formaldehyde and continue stirring at constant temperature for 50 minutes, then add 2.7 parts of urea for amination treatment, and then add The defoamer continued to stir for 8 minutes, and finally added the pH to neutral, cooled the temperature to room temperature and discharged, and used cotton yarn and organic solvent to remove oil and impurities on the surface to be attached. For oil and impurities, etc., cut a suitable small hole on the tip of the rubber tube, put it into the glue gun, drip the prepared glue to the center line of the substrate attachmen...

Embodiment 3

[0029]Put 45 parts of polyvinyl alcohol in a round bottom flask, add 8 parts of superfine barium sulfate, 5 parts of preservative, 5 parts of dispersant, 10 parts of butyl rubber and 150 parts of water, heat and stir, and keep the temperature at 95 °C Until the polyvinyl alcohol is completely dissolved, cool down to 80°C, add 38% hydrochloric acid dropwise and stir for 30 minutes to adjust the pH value, then add 35 parts of formaldehyde and continue stirring at constant temperature for 60 minutes, then add 3 parts of urea for amination treatment, and then add The defoamer continued to stir for 10 minutes, and finally added the PH to neutral, cooled the temperature to room temperature and discharged, and used cotton yarn and organic solvent to remove oil stains and impurities on the surface to be attached. For oil and impurities, etc., cut a suitable small hole on the tip of the rubber tube, put it into the glue gun, drip the prepared glue to the center line of the substrate att...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com