Positive electrode plate, negative electrode plate and high-rate rapid-charge lithium ion battery

A technology of lithium ion battery and positive pole piece, applied in battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problems of high battery temperature, battery capacity attenuation, abnormal battery heating, etc., to improve safety performance, The effect of reducing contact resistance and reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

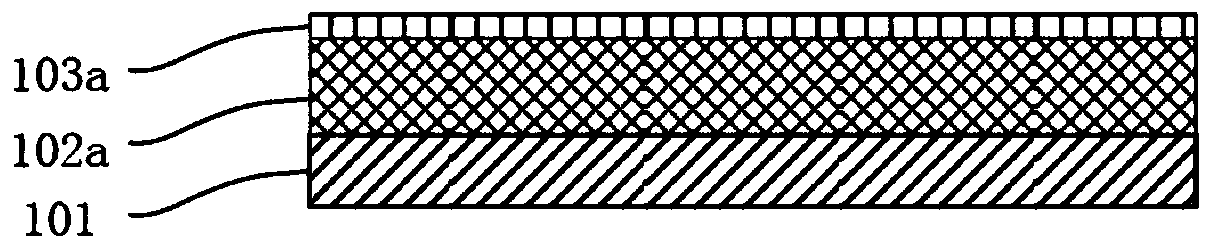

[0128] a. Preparation of cathode current collector

[0129] A common aluminum foil with a thickness of 22 μm was used as the positive current collector.

[0130] b. Preparation of positive electrode active material coating

[0131] With N-dimethylpyrrolidone (NMP) as the solvent, the positive electrode active material is nickel-cobalt manganese oxide lithium (NCM) with an average particle size of 4.5 μm (gram capacity 170mAh / g), and the electronic conductive agent is conductive carbon black (SP), Conductive graphite (KS-6), carbon nanotubes (CNTs), ion conductive agent is sulfonated graphene lithium salt, binder is polyvinylidene fluoride (PVDF). Wherein, the ion-conducting agent sulfonated graphene lithium salt content in the positive electrode active material coating is 0.3%, and the mass ratio of each substance in the coating is: NCM: SP: KS-6: CNTs: ion-conducting agent (sulfonated graphene Lithium salt): PVDF=93:2.8:1.1:0.5:0.1:2.5. First add PVDF to the solvent NMP, s...

Embodiment 2

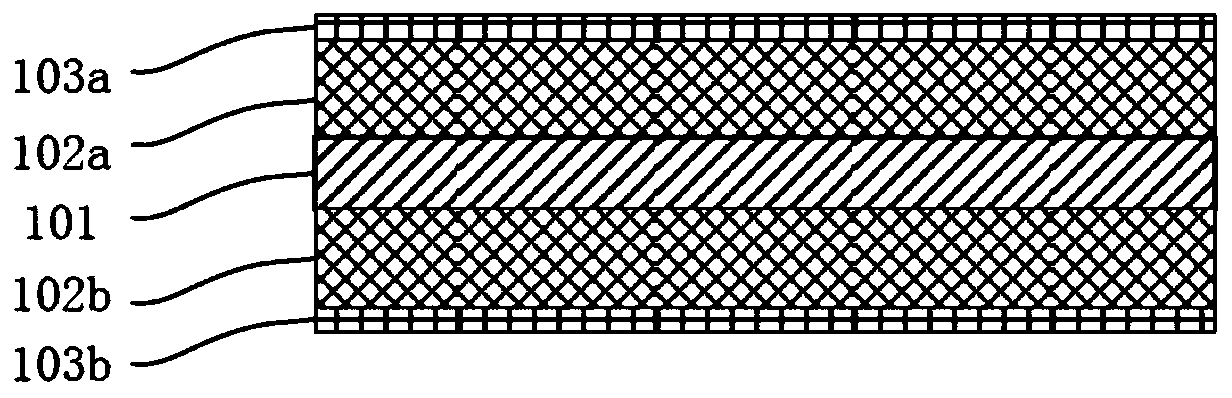

[0171] a. Preparation of cathode current collector

[0172] A porous aluminum / carbon composite foil with a thickness of 22μ is used as the current collector, which is purchased from the porous aluminum / carbon composite foil of Yudong Foil Technology Nantong Co., Ltd., model 20CP01.

[0173] b. Preparation of positive electrode active material coating

[0174] With N-dimethylpyrrolidone (NMP) as the solvent, the positive electrode active material is nickel-cobalt manganese oxide lithium (NCM) with an average particle size of 4.5 μm (gram capacity 170mAh / g), and the electronic conductive agent is conductive carbon black (SP), Conductive graphite (KS-6), carbon nanotubes (CNTs), ion conductive agent is sulfonated graphene lithium salt, binder is polyvinylidene fluoride (PVDF). Wherein, the ion-conducting agent sulfonated graphene lithium salt content in the positive electrode active material coating is 0.3%, and the mass ratio of each substance in the coating is: NCM: SP: KS-6: CN...

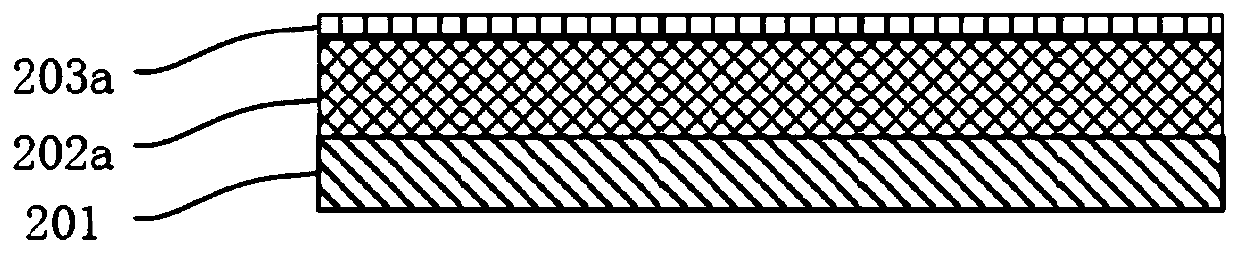

Embodiment 3

[0198] a. Preparation of cathode current collector

[0199] A porous aluminum / carbon composite foil with a porosity of 40% and a thickness of 22 μ was used as the current collector. The current collector was purchased from the porous aluminum / carbon composite foil of Yudong Foil Technology Nantong Co., Ltd., model 20CP02.

[0200] b. Preparation of positive electrode active material coating

[0201] The positive electrode active material coating is the same as the positive electrode active material coating prepared in b. the positive electrode active material coating in Example 1 of the battery.

[0202] c. Preparation of ion-conducting coating on the surface of the positive pole piece

[0203] The preparation of the ion-conductive coating on the surface of the positive pole piece is the same as that in c. the preparation of the ion-conductive coating on the surface of the positive pole piece in Example 1 of the battery.

[0204] d. Preparation of negative electrode collecto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com