Preparation method of high-efficiency antimony removal adsorbent and its application in printing and dyeing wastewater treatment

A printing and dyeing wastewater and adsorbent technology, which is applied in the field of water pollution treatment, can solve the problems of difficult to achieve standard discharge, low antimony efficiency and capacity, etc., and achieve the effects of stable and efficient preparation of materials, reduction of iron dissolution, and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

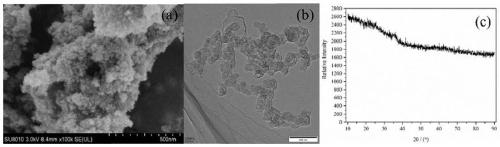

[0033] Embodiment 1: the preparation of the ODTMS type amorphous iron oxide-silicon dioxide composite material that the molar ratio of iron to silicon is 5:1

[0034] Weigh 0.8332g TEOS (tetraethyl orthosilicate) and 0.3747g octadecyltrimethoxysilane (Octadecyltrimethoxysilane, ODTMS) (both silicon molar ratio is 4:1) and dissolve them in 200mL absolute ethanol and 20ml water The mixed solution was added into a 1000mL three-hole flask, fixed in a constant temperature water tank to adjust the temperature to 60°C, and stirred at a speed of 300r / min for 10min. At the same time, 20g of 27%wt concentrated ammonia water was also weighed and added to a 100mL constant pressure funnel, and the ammonia solution was added dropwise until a white precipitate was produced; 50mL of FeCl with a molar concentration of 0.5M 3 After the solution is mixed evenly, it is added to a 100mL constant pressure funnel, and after 5 minutes of white precipitation, FeCl is added dropwise. 3 solution, while...

Embodiment 2

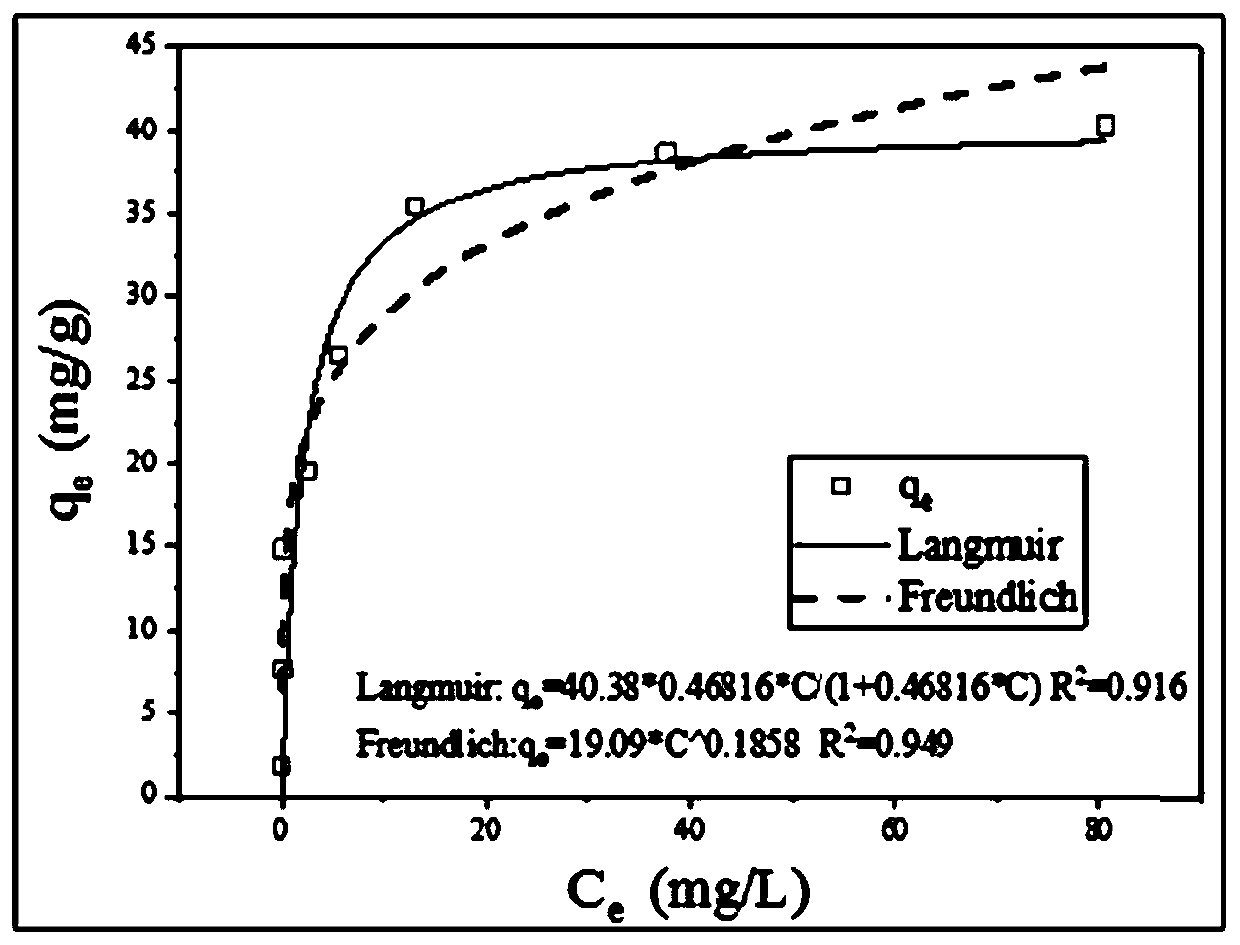

[0037] Example 2: Preparation of amorphous iron oxide-silicon dioxide composite material with different iron-silicon molar ratios and adsorption of antimony

[0038] According to the method for preparing iron-silicon composite materials in Example 1, composite materials with iron-silicon molar ratios of 1:1, 5:1, 10:1 and 20:1 were prepared respectively by changing the amount of iron salt added, and other preparations The conditions are the same as in Example 1. Then, the prepared iron-silicon composite material was used to adsorb antimony in water to explore the adsorption capacity of the composite material for antimony. Firstly, composite materials with different iron-silicon molar ratios were used to conduct a preliminary adsorption comparison of antimony solutions with an initial concentration of 200 μg / L (Table 1). %, while the antimony removal rate of the composite material with a molar ratio of iron to silicon of 5:1 is as high as 95%, indicating that too much silicon ...

Embodiment 3

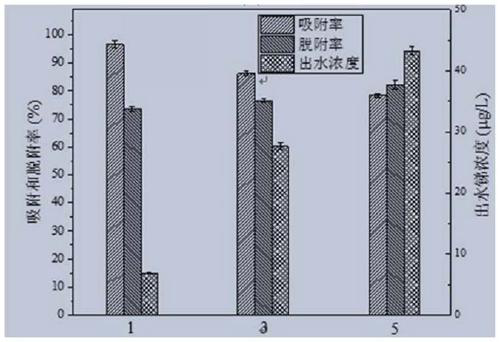

[0042] Example 3 Preparation of CTAB amorphous iron-silicon composite material with iron-silicon molar ratio of 5:1

[0043] The templating agent octadecyltrimethoxysilane in embodiment 1 is changed to hexadecyltrimethylammonium bromide CTAB, and the addition amount of TEOS is 1.0416g, and the addition amount of CTAB is 5g, and other preparation steps and iron solution Concentration and capacity are all identical with step and embodiment 1. The sintering condition is to heat up to 220°C at 5°C / min and then to 350°C at 1°C / min at the same air rate of 1L / min in a tube furnace, keep the temperature for sintering for 2 hours, and then cool down to room temperature. The material is ground and passed through a 60-mesh sieve to obtain a CTAB type amorphous iron oxide-silicon dioxide composite material. The comprehensive printing and dyeing wastewater of a printing and dyeing enterprise in Jiaxing, Zhejiang Province was treated with CTAB iron-silicon composite material. The main prop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com