A kind of highly water-soluble modified epoxy acrylic resin and preparation method thereof

A technology of epoxy acrylic acid and epoxy acrylate, which is applied in the direction of coating, etc., can solve the problems of insufficient hardness of the cured film, low water solubility of the resin, unstable storage, etc., to avoid the decline of physical and chemical properties, good hardness, and crosslinking high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

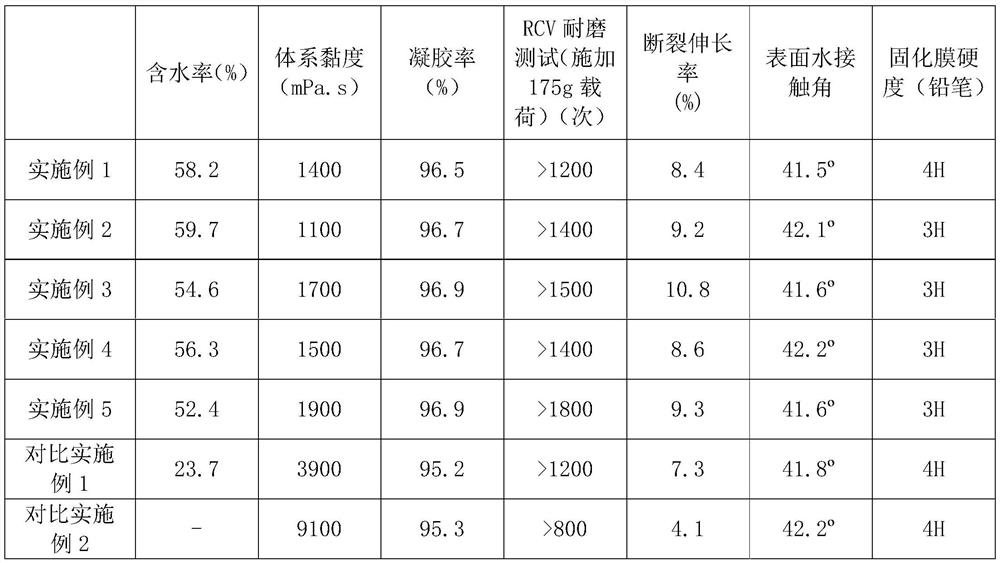

Examples

Embodiment 1

[0032] In the first step, add 250g of bisphenol A epoxy (epoxy E51) into a 500mL three-necked flask, heat the oil bath to 105°C, stir, and add acrylic acid (the molar ratio of epoxy group to acrylic acid is 1:1) Add a total mass of 0.8% catalyst N,N-diethylbenzylamine and 0.6% p-hydroxyanisole, and add it dropwise to the epoxy resin. After 4.5 hours of reaction, the acid value of the system is less than 3mgKOH / g, that is, the epoxy acrylic acid Ester ①; the second step, in a 1000mL three-necked flask, add 2mol of toluene diisocyanate (TDI), 38g of solvent ethylene glycol ether acetate, heated to 66 ° C, dibutyltin dilaurate by 0.6% of the total mass Add 1mol of 2,2-dimethylolbutyric acid, gradually add toluene diisocyanate (TDI) solution, and react for 3.5 hours to obtain water-based polyurethane segment ②; the third step is to synthesize the first step The epoxy acrylate ① is slowly added to the water-based polyurethane ② system synthesized in the second step, and the added a...

Embodiment 2

[0035] In the first step, add 450g of bisphenol A epoxy (epoxy E44) into a 1000mL three-necked flask, heat the oil bath to 115°C, stir, and add acrylic acid (the molar ratio of epoxy group to acrylic acid is 1:1) Add the total mass of 0.9% catalyst chromium trichloride and 0.6% p-hydroxyanisole, drop in the epoxy resin, and react for 4 hours, and the acid value of the system is less than 3mgKOH / g, to obtain epoxy acrylate ①; the second step , add 2mol of diphenylmethane diisocyanate (MDI) in a 1000mL three-necked flask, 35g of solvent propylene glycol methyl ether acetate, heat to 66 ° C, dibutyltin dilaurate is added to 1mol of 2,3-dihydroxypropionic acid, gradually added in diphenylmethane diisocyanate (MDI) solution, reacted for 3.5h to obtain water-based polyurethane segment; the third step, the epoxy acrylic acid synthesized in the first step The ester resin is slowly added to the water-based polyurethane system synthesized in the second step, and the amount of the epoxy ...

Embodiment 3

[0038] In the first step, add 500g of aliphatic epoxy resin into a 1000mL three-necked flask, heat the oil bath to 108°C, stir, and add a total mass of 0.5 % catalyst tetrabutylammonium bromide and 0.5% p-hydroxyanisole are added dropwise in the epoxy resin, and the acid value of the system is less than 3mgKOH / g after reacting for 3.5h to obtain epoxy acrylate ①; in the second step, Add 2mol of dicyclohexylmethane diisocyanate (HMDI) in the three-necked flask of 1000mL, 40g solvent propylene glycol butyl ether acetate, be heated to 76 ℃, dibutyltin dilaurate joins 1mol of 2 by 0.6% of gross mass, 2-Dihydroxymethylbutyric acid, gradually added in the dicyclohexylmethane diisocyanate (HMDI) solution, after reacting for 3.2h, the polyurethane segment that can be water-based is obtained; in the third step, the epoxy acrylic acid synthesized in the first step is Ester resin ① Slowly add to the water-based polyurethane system synthesized in the fourth step, the amount of epoxy acryl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com