Bismuth phosphate composite reduction graphene oxide material as well as preparation method and application thereof

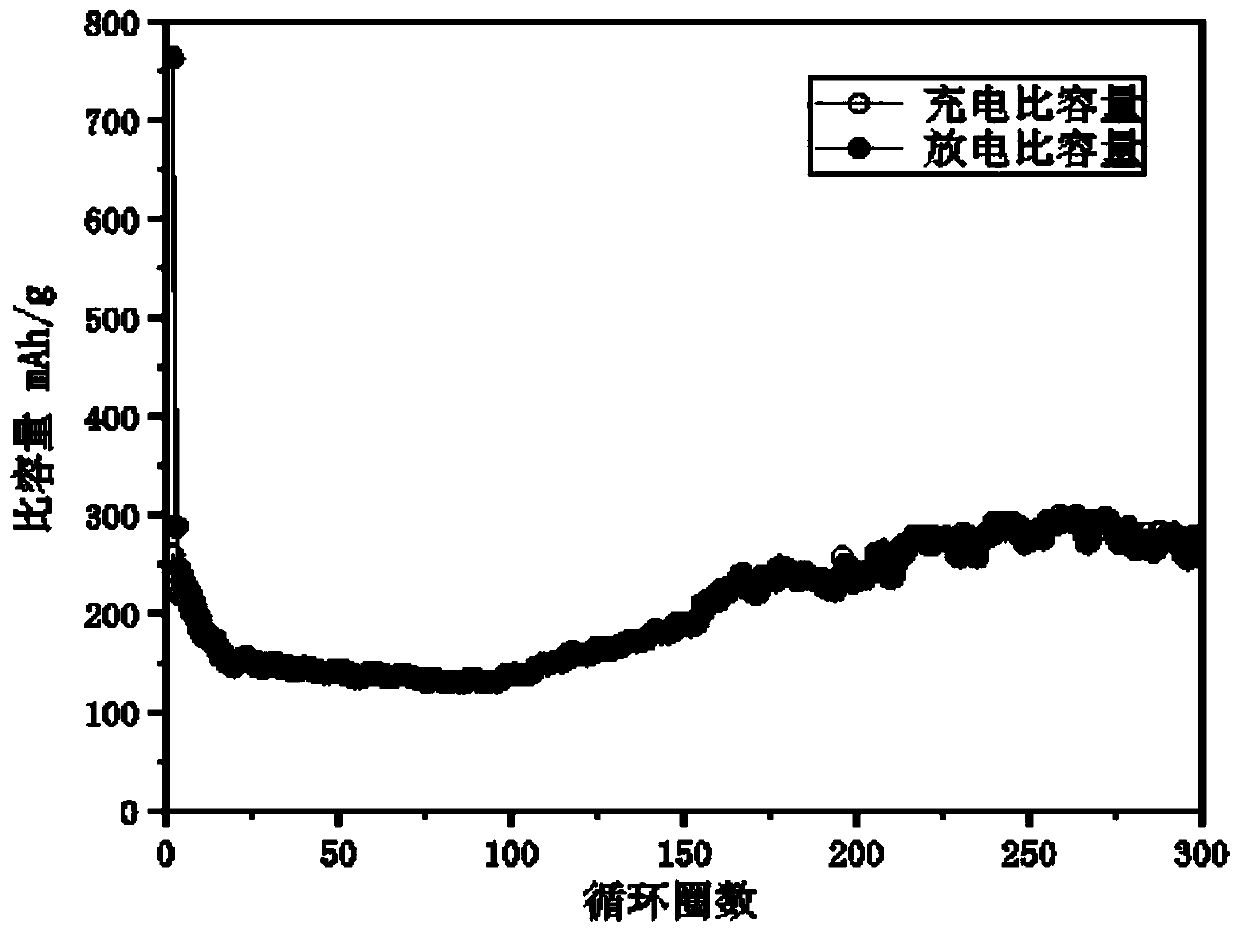

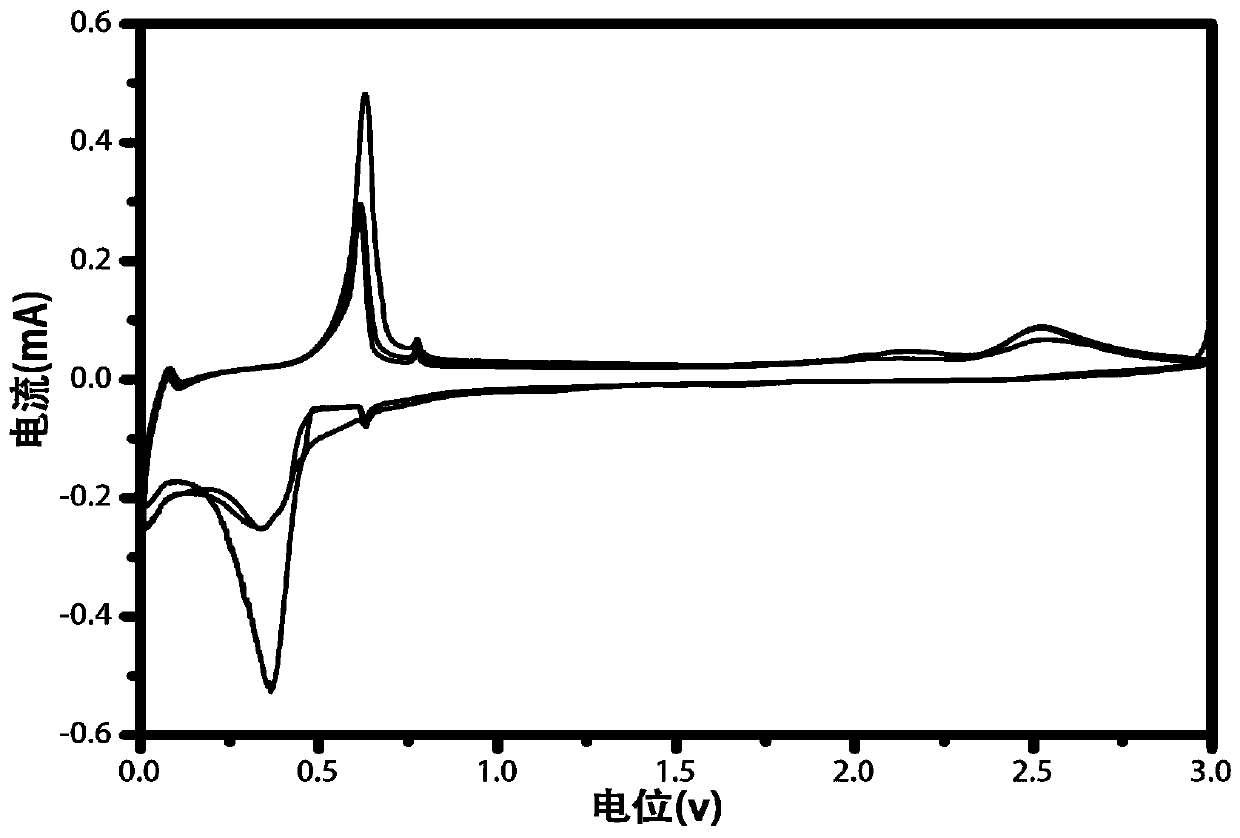

A technology of graphene and bismuth phosphate, which is applied in the field of composite materials, can solve the problems of unsuitability for large-scale production, cumbersome operation steps, and high energy consumption of the reaction, and achieve the effects of high repeatability, good cycle stability, and low reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a preparation method of a bismuth phosphate composite reduced graphene oxide material, comprising the following steps:

[0028] (1) Phosphorus source, graphene oxide and water are mixed to obtain a pre-dispersion;

[0029] (2) Mixing the bismuth source, the reducing agent and the pre-dispersion liquid for reduction reaction to obtain bismuth phosphate composite reduced graphene oxide.

[0030] The invention mixes phosphorus source, graphene oxide and water to obtain pre-dispersed liquid. In the present invention, the phosphorus source is phosphoric acid, and the phosphoric acid is added in the form of a phosphoric acid solution; the molar concentration of the phosphoric acid solution is preferably 1 to 6 mol / L, more preferably 2 to 4 mol / L; the predispersion The volume concentration of graphene oxide in the medium is 0.6-3 mg / mL, more preferably 1-2 mg / mL. In the present invention, it is also preferred to first prepare the graphene oxide into a ...

Embodiment 1

[0042] At normal temperature and pressure, add 10mL of 1mol / L phosphoric acid aqueous solution and 20mg of graphene oxide into 20mL of water, put them in a beaker, heat in a water bath and keep the temperature at 80°C, and stir for 10 minutes to obtain a pre-dispersion; then add 0.3854 Put 1 g of bismuth nitrate pentahydrate and 100 mg of ascorbic acid into the pre-dispersion liquid, stir at constant temperature for 8 hours, and the stirring speed is 150 r / min. Then the reaction kettle was naturally cooled to room temperature, the mixed solution was washed with ethanol and distilled water for 5 times, filtered, and the obtained powder was placed in a vacuum drying oven at 100°C for 8 hours in vacuum to obtain a bismuth phosphate composite reduced graphene oxide material BiPO 4 @rGO.

[0043] The resulting BiPO was analyzed using a scanning electron microscope 4 The morphology characteristics of @rGO were observed, and the resulting BiPO 4 Scanning electron microscope images...

Embodiment 2

[0047] At normal temperature and pressure, add 10mL of 1mol / L phosphoric acid aqueous solution and 20mg of graphene oxide into 10mL of water, put them in a beaker, heat in a water bath and keep the temperature at 60°C, and stir for 30 minutes to obtain a pre-dispersion; then add 0.3854 Put 1 g of bismuth chloride and 100 mg of hydrazine hydrate into the pre-dispersion liquid, stir at constant temperature for 6 hours, and the stirring speed is 100 r / min. Then the reaction kettle was naturally cooled to room temperature, the mixed solution was washed with ethanol and distilled water for 6 times, filtered, and the obtained powder was placed in a vacuum drying oven at 100°C for 12 hours in vacuum to obtain a bismuth phosphate composite reduced graphene oxide material BiPO 4 @rGO.

[0048] to the resulting BiPO 4 @rGO conducts XRD diffraction spectrum test. After analysis, the measured substance is bismuth phosphate material, and graphene oxide does not appear at the correspondin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com