Method of regenerating used denitration catalyst

A denitrification catalyst and catalyst technology, applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of reduced catalyst strength, difficult chemical solution treatment, easy residual ash components, etc., to achieve improved The effect of reuse times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

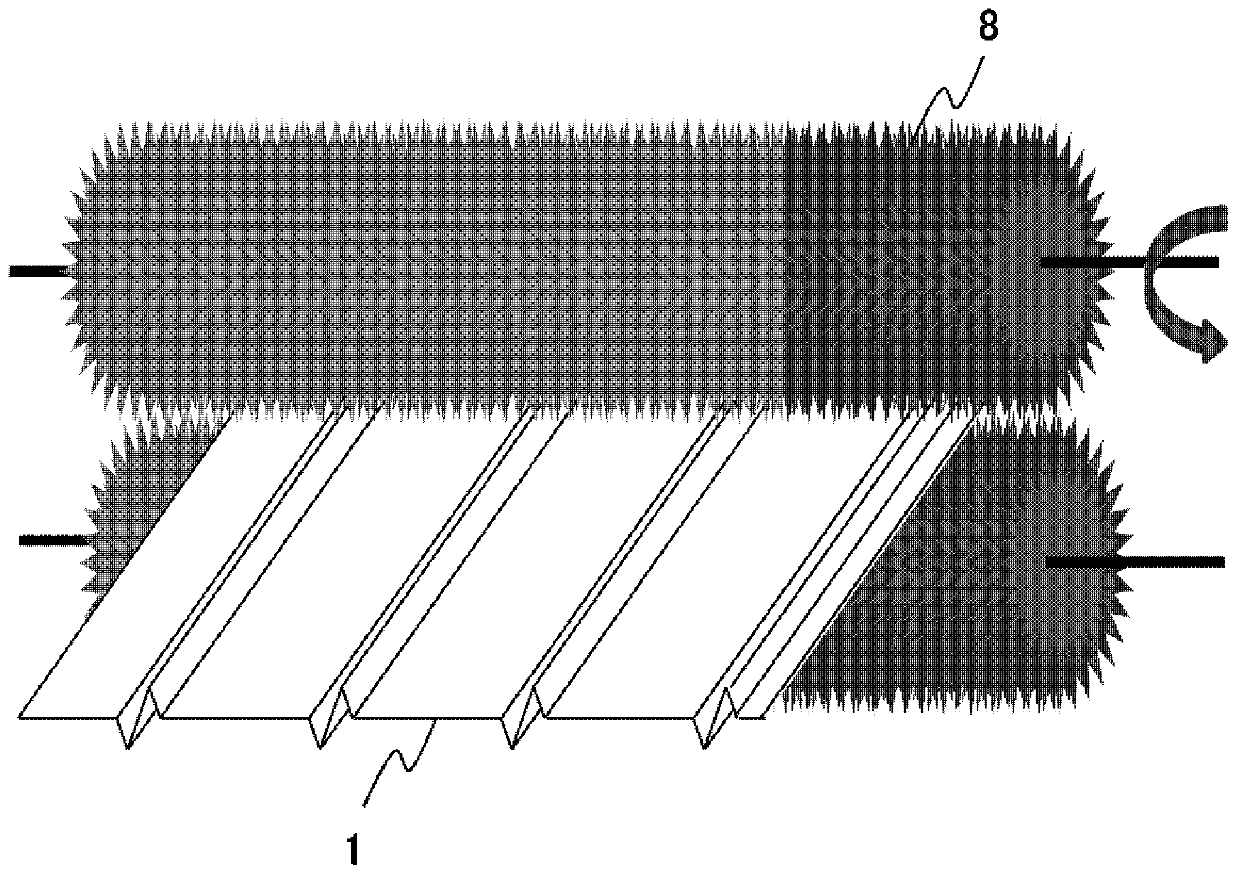

[0075] Production example 1 (catalyst 1)

[0076] Prepare a plate-shaped denitration catalyst element (catalyst 1) having a plate material comprising a metal strip with a thickness of 0.7 mm and a catalyst layer carried on the plate material by processing a SUS430 steel plate with a thickness of 0.2 mm. 0 ). The catalyst layer contains: Titanium oxide (TiO 2 ), tungsten oxide (WO 3 ) and vanadium oxide (V 2 o 5 ) catalyst component, 15% by mass of silica-alumina-based inorganic fibers relative to the catalyst component, and 8% by mass of the binder (SiO 2 ). Proceed to Catalyst I 0 Elemental quantitative analysis of surfaces. from Catalyst I 0 Catalyst pellets of 20 mm x 100 mm were cut out. It was used to determine the initial denitrification rate. The results are shown in Table 2.

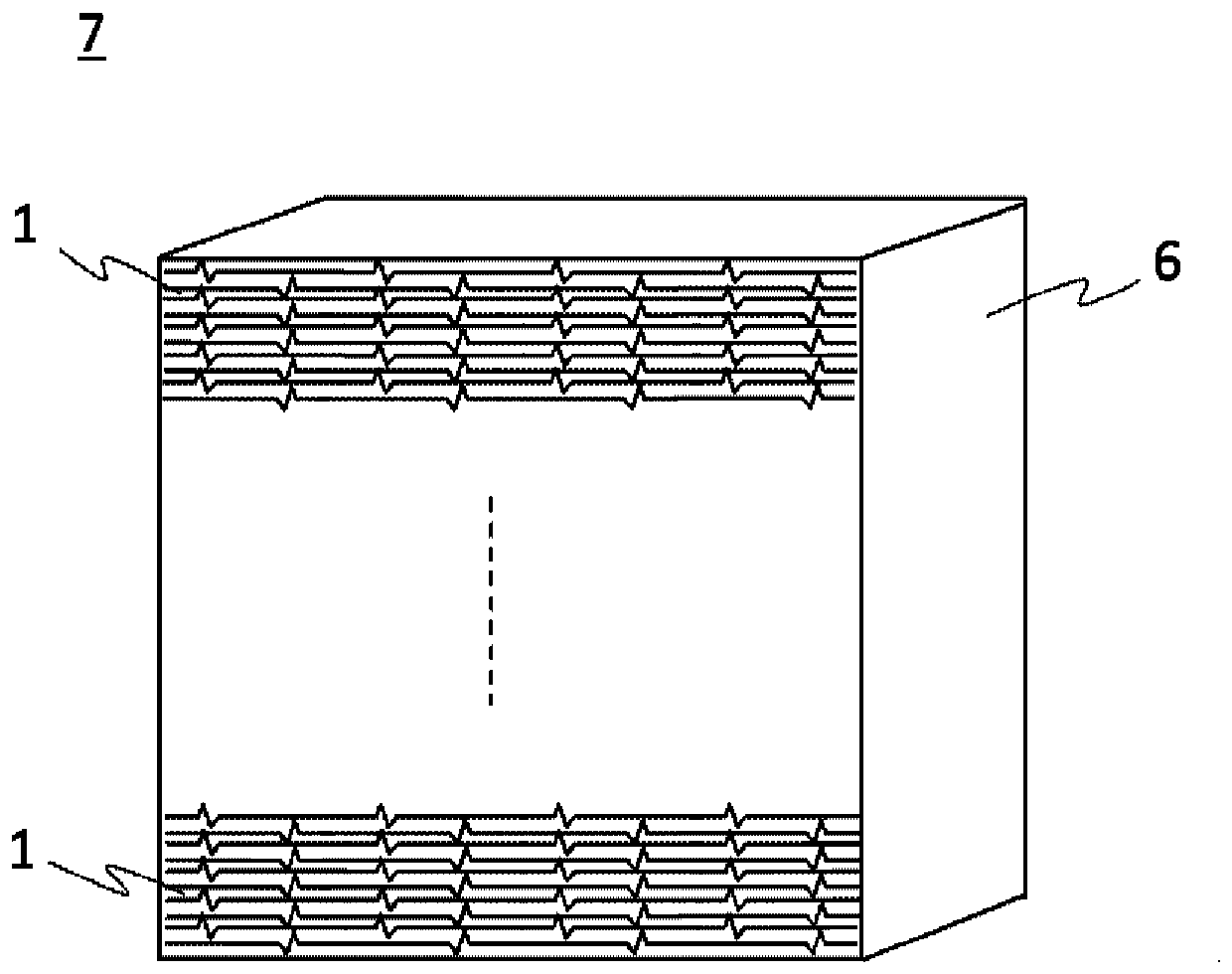

[0077] The plate-shaped denitration catalyst element (catalyst I 0 ) are stacked and accommodated in a unit frame to obtain a catalyst unit. The catalyst unit was installed in the de...

manufacture example 2

[0078] Production example 2 (catalyst II)

[0079] Prepare a plate-shaped denitration catalyst element (catalyst II 0 ). The catalyst layer contains: titanium oxide (TiO 2 ), molybdenum oxide (MoO 3 ) and vanadium oxide (V 2 o 5 ) catalyst component, 15% by mass of silica-alumina-based inorganic fibers relative to the catalyst component, and 2% by mass of the binder (SiO 2 ). Proceed to Catalyst II 0 Elemental quantitative analysis of surfaces. from Catalyst II 0 Catalyst pellets of 20 mm x 100 mm were cut out. It was used to determine the initial denitrification rate. The results are shown in Table 2.

[0080] The plate-shaped denitration catalyst element (catalyst II 0 ) are stacked and accommodated in a unit frame to obtain a catalyst unit. The catalyst unit is installed in the denitrification device of PRB coal-fired boiler exhaust gas in the United States and used for denitrification treatment for about 2 years. From this catalyst unit, the used plate-shaped...

reference example 1

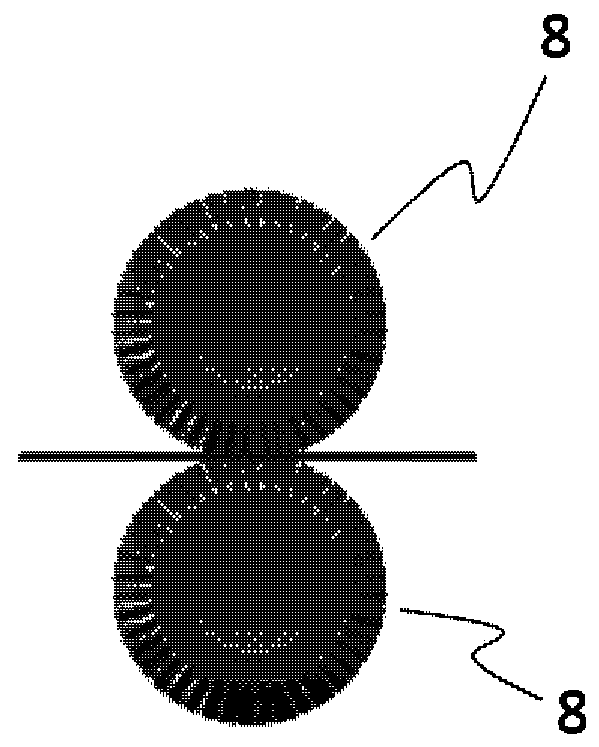

[0085] from Catalyst I 1 Catalyst sheets of 100 mm x 100 mm were cut out. The catalyst sheet was immersed in a 60°C, 5% by mass aqueous oxalic acid solution. The surface of the catalyst sheet was brushed 20 times with a resin brush (bristles: made of resin, diameter: 200 μm / bristle, hair length: 10 mm) while immersed in the oxalic acid aqueous solution. The catalyst sheet was allowed to dry naturally. Quantitative analysis of elements on the surface of the obtained cleaned catalyst sheet was performed to calculate the coverage. The results are shown in Table 3. Coverage is drastically reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com