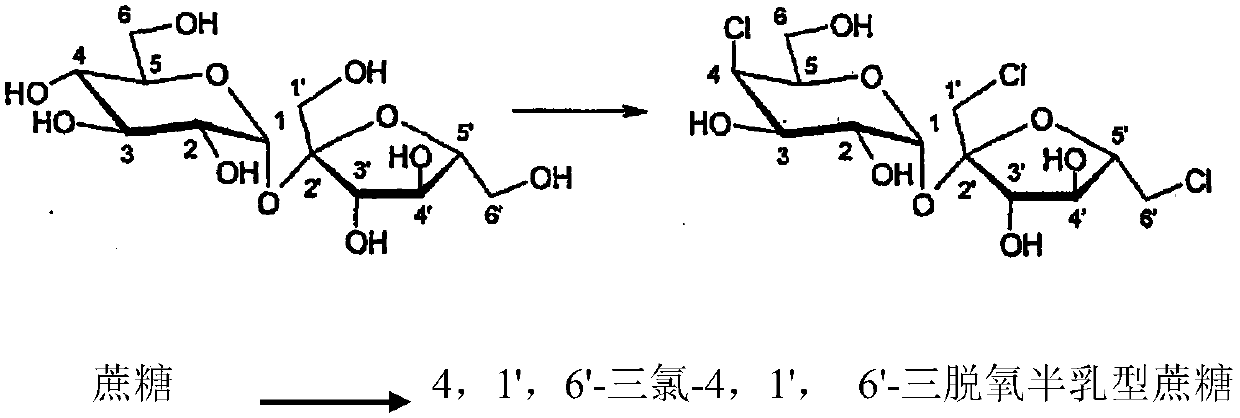

Neutralization method of chlorination solution

A technology of chlorination reaction and reaction solution, applied in chemical instruments and methods, neutralized water/sewage treatment, sugar derivative preparation, etc., can solve problems such as irritating odor, decomposition, increase environmental protection treatment costs, etc. degree, reduce losses, and promote the effect of reducing pollution and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

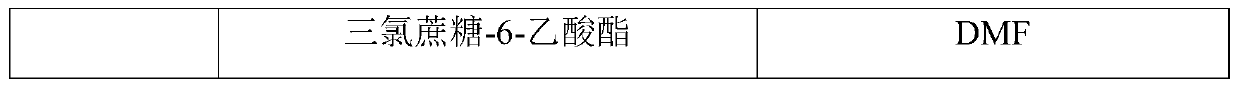

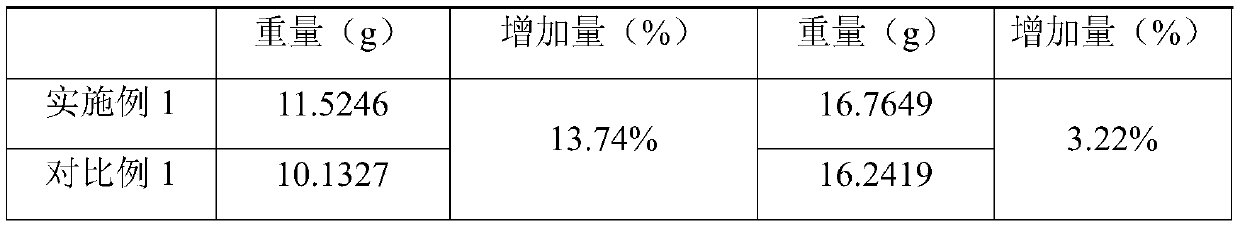

[0025] Take by weighing 270g of reaction solution and place in conical flask, this reaction solution is obtained by chlorination reaction of sucrose-6-ethyl ester in DMF solvent or under the environment of DMF solvent and other solvents and thionyl chloride or carbonyl chloride, Wherein other solvents may be toluene, pyridine or tetrahydrofuran, etc., after cooling and stirring, 30 wt% sodium carbonate aqueous solution is added dropwise at 25°C to neutralize to a pH value of 6.5.

[0026] Add dropwise a 32 wt% sodium hydroxide solution to neutralize to a pH of 9.0, and stir for 0.5 hours until the pH is stable.

[0027] Concentrated hydrochloric acid solution was added dropwise to adjust the pH of the reaction solution to 7.0.

[0028] As detected by HPLC, the content of sucralose-6-acetate was 5.63 wt%, and the content of DMF was 8.19 wt%. According to the mass calculation, 11.5246g of sucralose-6-acetate and 16.7649g of DMF were obtained in this implementation

Embodiment 2

[0039] Take by weighing 270g of reaction solution and place in conical flask, this reaction solution is obtained by chlorination reaction of sucrose-6-ethyl ester in DMF solvent or under the environment of DMF solvent and other solvents and thionyl chloride or carbonyl chloride, Wherein other solvents may be toluene, pyridine or tetrahydrofuran, etc., after cooling and stirring, 28wt% sodium carbonate aqueous solution is added dropwise at 25°C to neutralize to a pH value of 6.8.

[0040] Add 32 wt% aqueous sodium hydroxide solution dropwise to neutralize to a pH of 9.0, and stir for 0.5 hours until the pH is stable.

[0041] Concentrated hydrochloric acid solution was added dropwise to adjust the pH of the reaction solution to 7.0.

[0042] As detected by HPLC, the content of sucralose-6-acetate was 5.38wt%, and the content of DMF was 7.91wt%. According to the mass calculation, 11.0692 g of sucralose-6-acetate and 16.4886 g of DMF were obtained in this implementation.

Embodiment 3

[0044] Take by weighing 270g of reaction solution and place in conical flask, this reaction solution is obtained by chlorination reaction of sucrose-6-ethyl ester in DMF solvent or under the environment of DMF solvent and other solvents and thionyl chloride or carbonyl chloride, Wherein other solvents may be toluene, pyridine or tetrahydrofuran, etc., cooled and stirred to 25°C. Use recovered tower top water, its DMF content is 2.7wt%, preparation 28wt% sodium carbonate aqueous solution. At a temperature of 25° C., a 28 wt % sodium carbonate aqueous solution was added dropwise to neutralize to a pH value of 6.8.

[0045] Add 32 wt% aqueous sodium hydroxide solution dropwise to neutralize to a pH of 9.0, and stir for 0.5 hours until the pH is stable.

[0046] Concentrated hydrochloric acid solution was added dropwise to adjust the pH of the reaction solution to 7.0.

[0047]As detected by HPLC, the content of sucralose-6-acetate was 5.38wt%, and the content of DMF was 8.59wt%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com