Fiber-modified soybean protein-based adhesive for wood-based panels and preparation method thereof

A soybean protein and modifier technology, applied in the preparation of protein adhesives, animal glue or gelatin, adhesives, etc., can solve the problems of poor dispersibility and low reactivity, and achieve good water resistance, excellent fiber dispersion effect, close-knit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation of soybean protein-based adhesive, comprising:

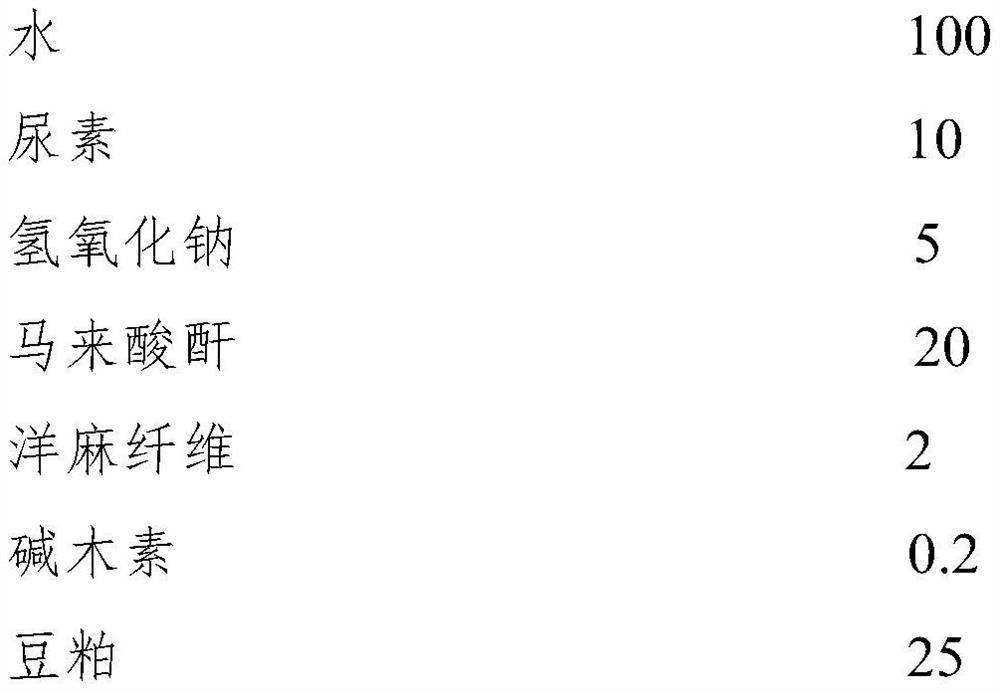

[0035] (1) Prepare materials according to the following weight ratio (Kg):

[0036]

[0037] (2) Disperse 2Kg of kenaf fibers into a solution containing 0.2Kg of alkali lignin, disperse the kenaf fibers evenly, stir, rinse and dry at a rotating speed of 900 rpm, and obtain dispersible, highly reactive Kenaf fiber.

[0038] (3) Disperse 5Kg of sodium hydroxide and 10Kg of urea in water, and stir evenly at a rotating speed of 900 rpm to obtain a mixed solution of sodium hydroxide and urea.

[0039] (4) Disperse the modified kenaf fibers into a mixed solution of sodium hydroxide and urea, and stir evenly at a rotating speed of 900 rpm to obtain a mixed solution of sodium hydroxide and urea containing kenaf fibers.

[0040] (5) Add the mixed solution of sodium hydroxide and urea containing kenaf fiber to 25Kg soybean meal under the stirring condition of rotating speed 900 rev / min, obtain the soybean meal de...

Embodiment 2

[0046] A preparation of soybean protein-based adhesive, comprising:

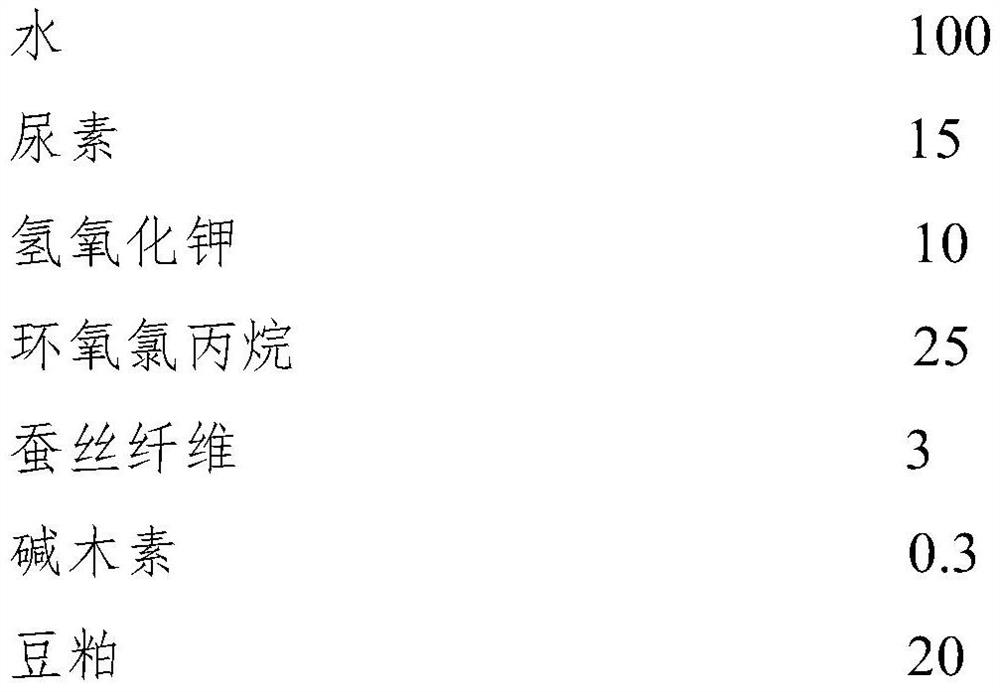

[0047] (1) Prepare materials according to the following weight ratio (Kg):

[0048]

[0049](2) Disperse 3Kg of silk fibers into a solution containing 0.3Kg of alkali lignin to disperse the silk fibers evenly. After stirring, rinsing and drying at a speed of 1000 rpm, silk fibers with excellent dispersibility and high reactivity are obtained .

[0050] (3) Disperse 10Kg of potassium hydroxide and 15Kg of urea in water, and stir evenly at a rotating speed of 1000 rpm to obtain a mixed solution of potassium hydroxide and urea.

[0051] (4) Disperse the modified silk fibers into a mixed solution of potassium hydroxide and urea, and stir evenly at a rotating speed of 1000 rpm to obtain a mixed solution of potassium hydroxide and urea containing silk fibers.

[0052] (5) Add the mixed solution of potassium hydroxide and urea containing silk fiber to 20Kg soybean meal under the stirring condition of rotating ...

Embodiment 3

[0058] A preparation of soybean protein-based adhesive, comprising:

[0059] (1) Prepare materials according to the following weight ratio (Kg):

[0060]

[0061] (2) Disperse 2.5Kg of wood fibers into a solution containing 0.3Kg of tannic acid to disperse the wood fibers evenly. After stirring, rinsing and drying at a rotating speed of 1100 rpm, wood fibers with excellent dispersibility and high reactivity are obtained. fiber.

[0062] (3) Disperse 8Kg of calcium hydroxide and 15Kg of urea in water, and stir evenly at a rotating speed of 1100 rpm to obtain a mixed solution of calcium hydroxide and urea.

[0063] (4) Disperse the modified wood fiber into a mixed solution of calcium hydroxide and urea, and stir evenly at a rotating speed of 1000 rpm to obtain a mixed solution of calcium hydroxide and urea containing wood fiber.

[0064] (5) Add the mixed solution of calcium hydroxide containing wood fiber and urea to 20Kg soybean meal under the stirring condition of rotati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com