High-performance ceramic coating, preparation method thereof and application

A ceramic coating, high-performance technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of uniform coating on the surface of workpiece, low bonding strength of film base, poor material controllability, etc. , to achieve the effect of strong bonding force of the film base, low processing temperature, and not easy to peel off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

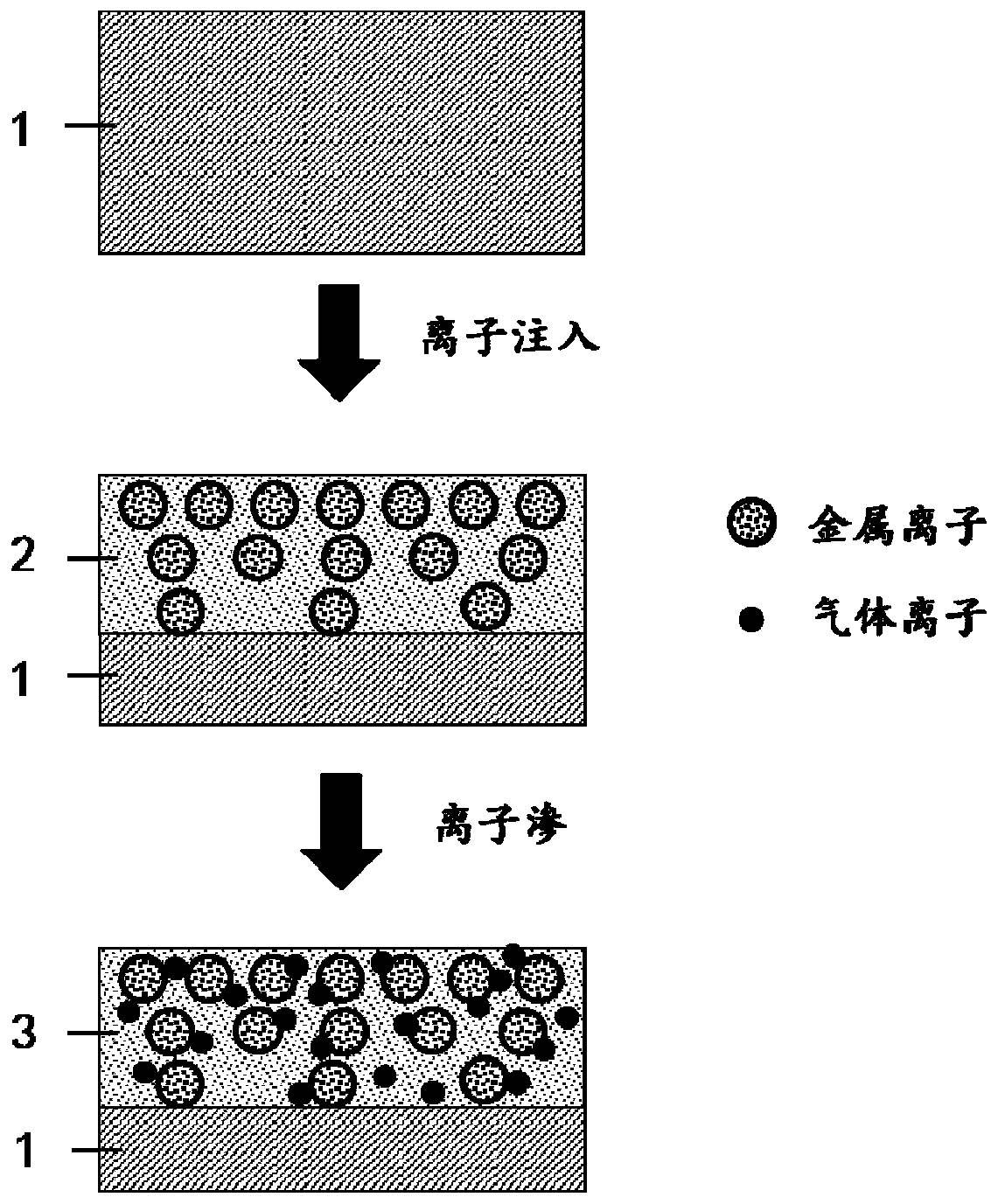

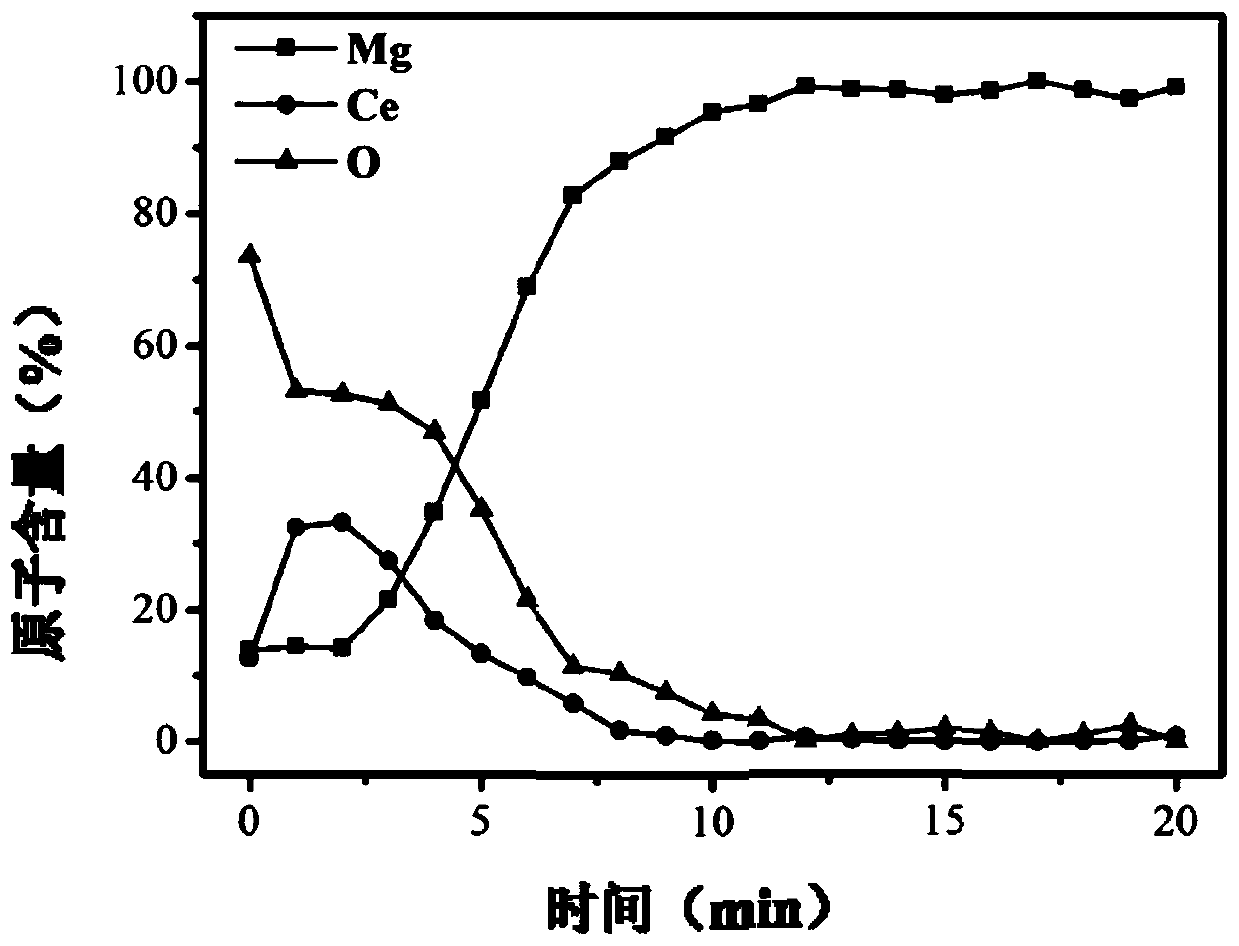

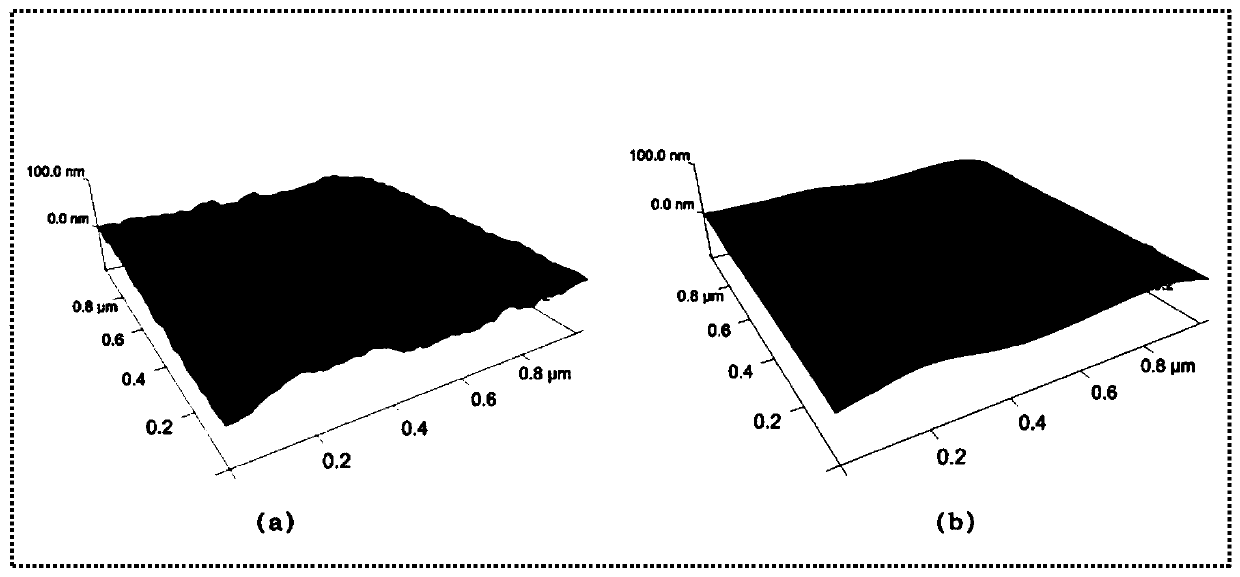

[0030] In this example, CeO is prepared on the surface of magnesium substrate. 2 ceramic coating. Before the experiment, the substrate 1 was cleaned with alcohol, and after drying, it was placed in a vacuum chamber and bombarded with Ar ions to remove surface contamination. Coating preparation process such as figure 1 shown. First, the MEVVA ion source uses metal vacuum arc discharge to generate high-density Ce ions, which are extracted by the electrode extraction system and accelerated to become energy-carrying ion beams. The injection voltage is 100 kV. The energetic ion beam implants Ce ions into the surface of the substrate 1 , and the cerium element is distributed in a gradient in the substrate 1 to form the metal coating 2 . During injection, the vacuum chamber pressure was 10 -3 Pa, Ce ion implantation dose is 10 16 icon·cm -2 , the beam density is 250 μA / cm 2 , and the injection time was 90 min. By controlling the Ce ion implantation dose, implantation energy...

Embodiment 2

[0033]In this example, the preparation method of the high-performance ceramic coating is applied to the energy industry, and an aluminum oxide coating is plated on the inner surface of the hydrogen storage tank.

[0034] Steel (Q345R) is generally used as the material of the hydrogen storage tank. However, during the storage of hydrogen, hydrogen atoms tend to diffuse into the steel and eventually become hydrogen molecules, which generate pressure inside the material and cause stress concentration. If the strength limit of the steel is exceeded, small cracks will be generated inside the steel, which will eventually lead to fracture, that is, hydrogen embrittlement. Al plating on the inner surface of the hydrogen storage tank 2 o 3 Ceramic coatings can effectively prevent hydrogen embrittlement from occurring. The diffusion process of hydrogen in the alumina coating requires a certain amount of energy to break the bond between aluminum and oxygen, and then play a good role in...

Embodiment 3

[0037] In this embodiment, the method for preparing a high-performance ceramic coating is applied to the semiconductor field, and an AlN coating is plated on the surface of the Invar alloy.

[0038] AlN has high breakdown field strength, high thermal conductivity, high resistivity, high chemical and high thermal stability, and is a good semiconductor material. The method of this example is similar to that of Example 1. Firstly, Al ions are implanted on the surface of Invar alloy by MEVVA ion source technology, and then N element is infiltrated on the surface of the treated substrate by ion infiltration technology to generate 10 μm AlN with gradient structure in situ. ceramic coating. During injection, the vacuum chamber pressure was 10 -3 Pa, MEVVA ion source implantation voltage is 200 kV, Al ion implantation dose is 10 17 icon·cm -2 , the beam density is 500 μA / cm 2 , and the injection time was 180 min. During the ionization process, a bias voltage of -500 V was applie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com