Structure and preparation method of high-utilization-rate manganese oxide electrode of neutral zinc-manganese battery

A zinc-manganese battery, manganese oxide technology, applied in battery electrodes, electrode manufacturing, active material electrodes, etc., can solve the problems of low porosity, low stacking density of pole pieces, poor electronic and ionic conductivity, etc., and achieve high specific capacity. , the effect of high energy density and excellent ion conduction structural characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 60 grams of manganese oxide, 5 grams of sodium dodecylbenzene sulfonate, 20 grams of graphite and other materials, add 400 grams of deionized water, perform ball milling for 24 hours and fully disperse.

[0028] (2) Add 3 grams of methyl methacrylate and 8 grams of sodium carboxymethyl cellulose to the dispersion in step (1), and continue stirring to form a positive electrode slurry.

[0029] (3) Put the slurry in step (2) in an oven at 80° C., dry for 24 hours, and then pulverize and grind to obtain a powder material.

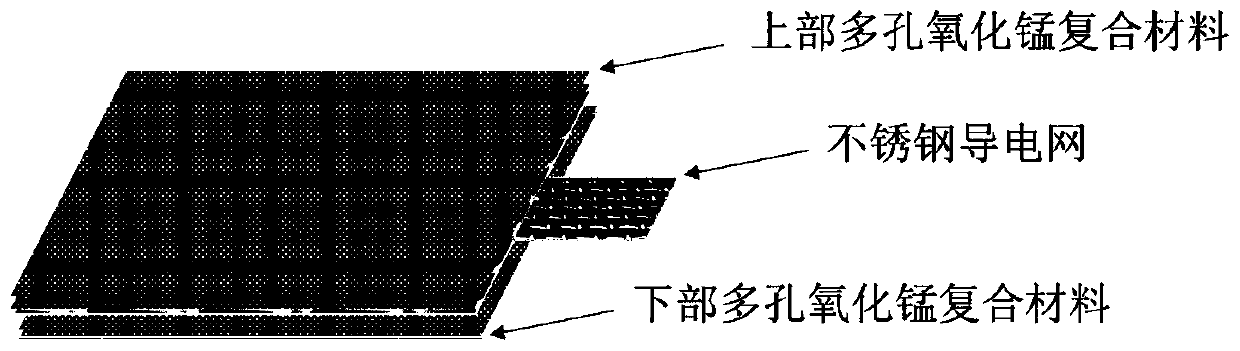

[0030] (4) Weigh 5 grams of the powder material obtained in step (3), and put 2.5 grams of powder material evenly at the bottom of the tablet-type abrasive tool, and put it into a 3 cm and 6 cm length and width respectively. Stainless steel conductive mesh, and then evenly place the remaining powder on the surface of the conductive mesh, control the pressure at 50MPa, take it out after holding the pressure for 30 minutes, and you can get a hig...

Embodiment 2

[0033] (1) Weigh 80 grams of manganese oxide, 3 grams of sodium hexametaphosphate, 10 grams of acetylene black, 10 grams of carbon nanotubes and other materials, add 200 grams of deionized water, and perform 24-hour ball milling to form a viscous dispersion system .

[0034] (2) Add 1 gram of methyl methacrylate and 5 grams of polytetrafluoroethylene to the dispersion system of step (1), and continue stirring to form a positive electrode paste.

[0035] (3) Put the paste in step (2) into a roller press, control the pressure to 10MPa, and press it into a sheet-shaped positive electrode semi-finished product, then place the three-dimensional porous foamed carbon in the roller press, and place the two positive electrodes The semi-finished products are respectively placed on the two sides of the three-dimensional porous carbon foam, and the control pressure is 30MPa. After rolling, the manganese oxide electrode pole piece with high utilization rate can be obtained.

[0036] In or...

Embodiment 3

[0038] (1) Weigh 100 grams of manganese oxide, 5 grams of polyvinyl alcohol, 20 grams of graphite, 10 grams of acetylene black and other materials, add them into 600 grams of deionized water, perform ball milling for 24 hours and fully disperse them.

[0039] (2) Add 3 grams of ethylene methyl acrylate and 15 grams of polyacrylate to the dispersion in step (1), and continue stirring to form a positive electrode slurry.

[0040] (3) Place the slurry in step (2) in an oven at 70° C., dry for 24 hours, and then pulverize and grind to obtain a powder material.

[0041] (4) Weigh 10 grams of the powder material obtained in step (3), first put 5 grams of powder material evenly at the bottom of the tablet-type abrasive tool, and put it into a 5 cm and 10 cm length and width respectively. Carbon felt conductive grid, and then evenly place the remaining powder on the surface of the conductive grid, control the pressure at 60MPa, take it out after holding the pressure for 30 minutes, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com