Nanometer composite negative material and preparation method and application thereof

A negative electrode material, nanocomposite technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low capacity and low cycle stability of silicon-based negative electrode materials, and can reach the synthesis scale. Amplification, high mechanical strength, good ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

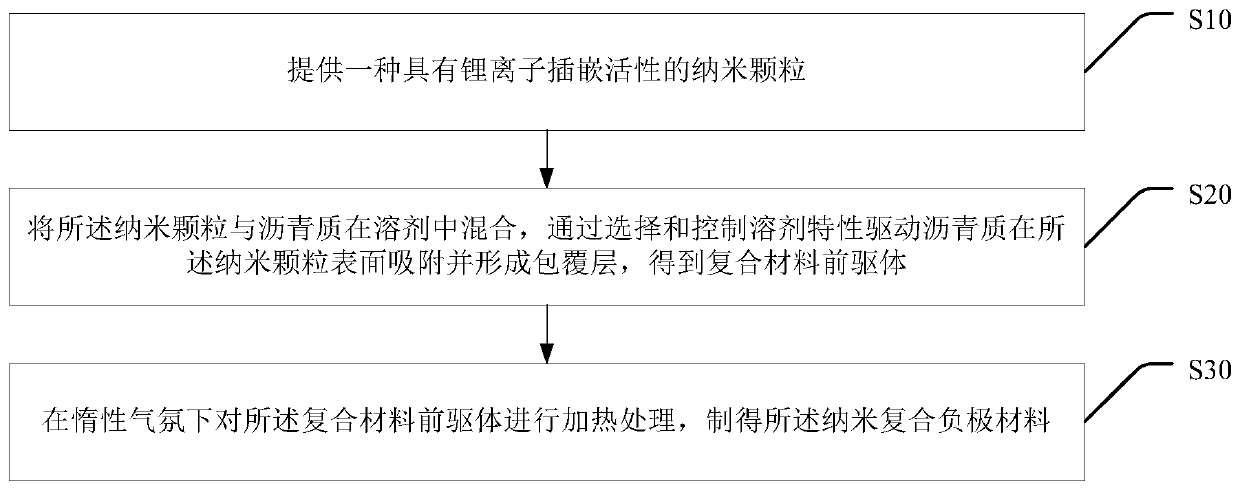

Method used

Image

Examples

Embodiment 1

[0062] A method for preparing a silicon-carbon negative electrode material and testing thereof, comprising the following steps:

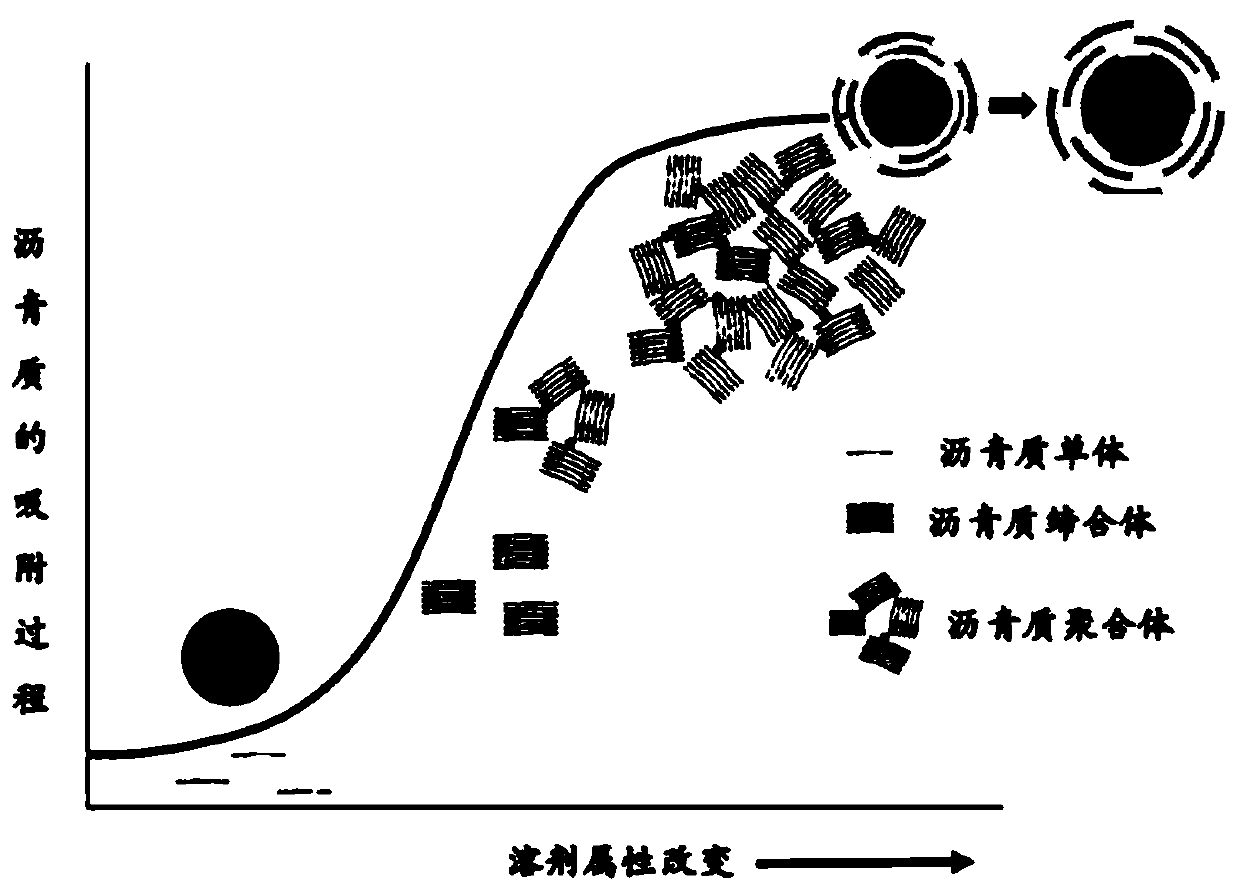

[0063] The first step, asphaltene adsorption: add 50mg of silicon powder with a diameter of 100nm to 100ml of 1.0g / L toluene solution of asphaltene molecules, and mechanically stir for 12 hours to drive the asphaltene molecules to the surface of the core material.

[0064] The second step, drying: remove the supernatant after centrifugation at 8000rpm / min, and dry the remaining silica mud in the tube for 12 hours in a vacuum oven at 50°C to remove the solvent.

[0065] The third step, high-temperature treatment: put the asphaltene-coated silicon powder in a heated quartz tube, and under the protection of an inert gas, first raise the temperature at 5°C per minute to 100°C, keep it warm for 10 minutes, and then heat it at 5°C / min The heating rate was raised to 800° C., kept for 1 h, and cooled to room temperature to obtain the asphaltene adsorption l...

Embodiment 2

[0069] A method for preparing a silicon-carbon negative electrode material and testing thereof, comprising the following steps:

[0070] The first step, solvent transition method: add 50mg of silicon powder with an average diameter of 100nm to the toluene solution of 1.0g / l asphaltene molecules, and slowly drop a certain amount of methanol solution, so that the final volume ratio of toluene and methanol is 8:2 , stirred for 12 hours, driving the first layer of asphaltene molecules to the surface of the core material. After 12 hours, slowly drop a certain amount of heptane, so that the final volume ratio of the mixed solution of heptane, toluene and methanol is 8:2, and drive the second layer of asphaltene molecules to the surface of the first layer of asphaltene molecules.

[0071] The second step, drying: remove the supernatant after centrifugation at 8000rpm / min, and dry the remaining silica mud in the tube for 12 hours in a vacuum oven at 50°C to remove the solvent.

[007...

Embodiment 3

[0076] A method for preparing a silicon-carbon negative electrode material and testing thereof, comprising the following steps:

[0077] The first step, asphaltene adsorption: add 50mg of silicon powder with a diameter of 100nm to 100ml of 1.0g / L toluene solution of asphaltene molecules, and stir for 12 hours to drive the asphaltene molecules to the surface of the core material.

[0078] The second step, drying: remove the supernatant after centrifugation at 8000rpm / min, and dry the remaining silica mud in the tube for 12 hours in a vacuum oven at 50°C to remove the solvent.

[0079] The third step, high-temperature treatment: put the asphaltene-coated silicon powder in a heated quartz tube, and under the protection of an inert gas, first raise the temperature at 5°C per minute to 100°C, keep it warm for 10 minutes, and then heat it at 5°C / min The heating rate was raised to 600° C., kept for 1 h, and cooled to room temperature to obtain a high-temperature treated asphaltene ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com