Method for modifying aromatic polyamide composite membrane active layer and application thereof

An aromatic polyamide and composite membrane technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. , Improve the effect of anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

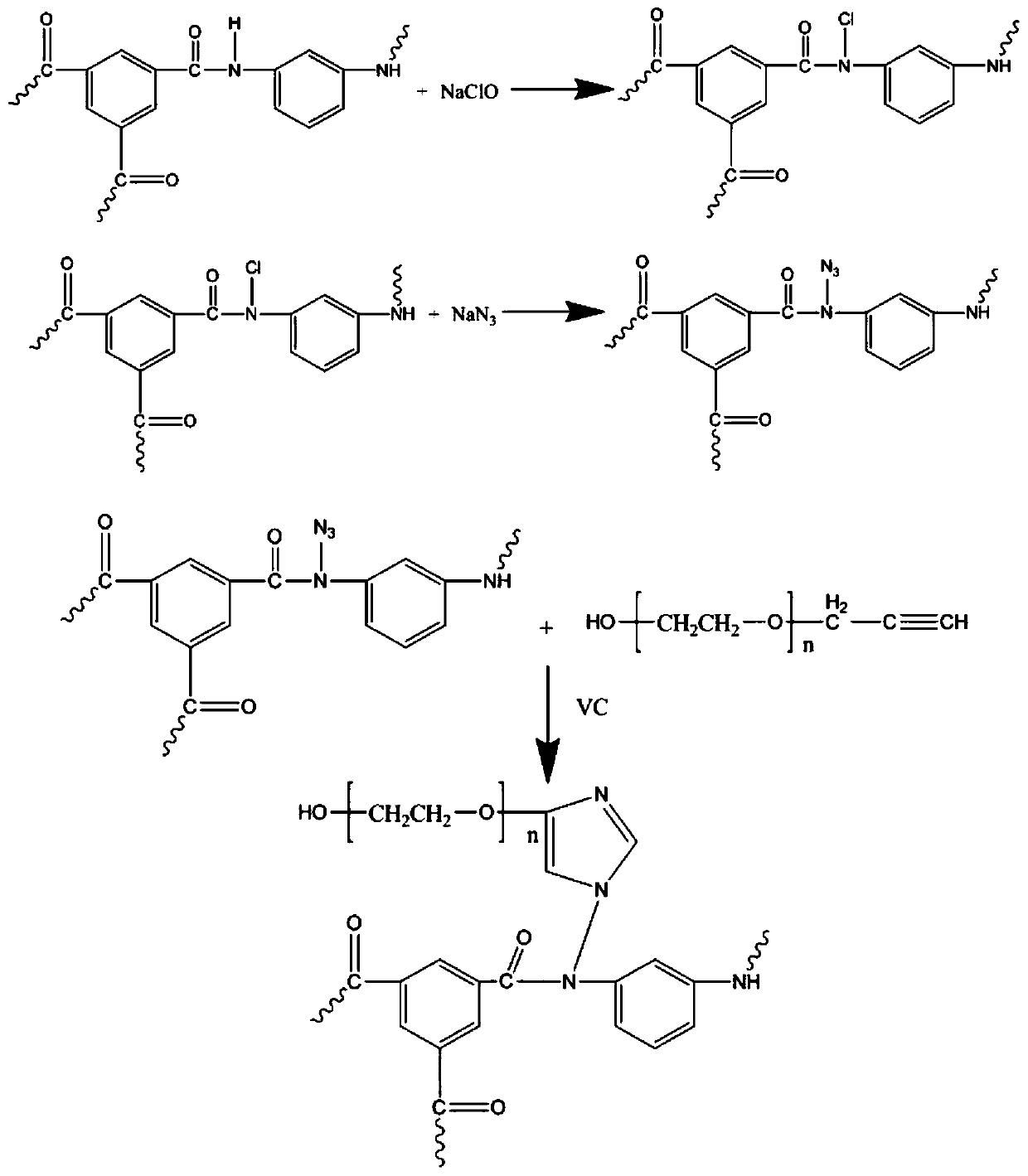

[0029] A preparation method for a modified aromatic polyamide active layer, comprising the following steps:

[0030] Step 1: 19g of methoxypolyethylene glycol mPEG with an average molecular weight of 1900 g / mol, 4g of propyne bromide and 12g of sodium hydroxide powder are placed in a reaction flask equipped with toluene solvent, mixed evenly, heated in a water bath to 50°C, magnetically stirred for 24 hours, after the reaction was complete, the solvent was removed by rotary evaporation, and the residue was mixed with anhydrous dichloromethane CH with a volume ratio of 1:1. 2 Cl 2 Extract with a mixed solvent of saturated saline to obtain an organic phase, then dry the organic phase with anhydrous magnesium sulfate, filter, and settle with ice anhydrous ether three times, and after filtration, polyethylene glycol monomethanol containing terminal alkyne groups is obtained. Ether (1900 g / mol);

[0031] Step 2: Take 0.01mL of sodium hypochlorite solution and dissolve it in 1000m...

Embodiment 2

[0035] A preparation method for a modified aromatic polyamide active layer, comprising the following steps:

[0036]Step 1: 10g of methoxypolyethylene glycol mPEG with an average molecular weight of 1000 g / mol, 4g of propyne bromide and 12g of sodium hydroxide powder are placed in a reaction flask equipped with toluene solvent, mixed evenly, heated in a water bath to 50°C, magnetically stirred for 24 hours, after the reaction was complete, the solvent was removed by rotary evaporation, and the residue was mixed with anhydrous dichloromethane CH at a volume ratio of 1:1. 2 Cl 2 Extract with a mixed solvent of saturated saline to obtain an organic phase, then dry the organic phase with anhydrous magnesium sulfate, filter, and settle with ice anhydrous ether three times, and after filtration, polyethylene glycol monomethanol containing terminal alkyne groups is obtained. Ether (1000 g / mol);

[0037] Step 2: Take 0.02mL of sodium hypochlorite solution and dissolve it in 1000mL o...

Embodiment 3

[0041] A preparation method for a modified aromatic polyamide active layer, comprising the following steps:

[0042] Step 1: 5g of methoxypolyethylene glycol mPEG with an average molecular weight of 500 g / mol, 4g of propyne bromide and 12g of sodium hydroxide powder are placed in a reaction flask equipped with toluene solvent, mixed evenly, heated in a water bath to 50°C, magnetically stirred for 24 hours, after the reaction was complete, the solvent was removed by rotary evaporation, and the residue was mixed with anhydrous dichloromethane CH at a volume ratio of 1:1. 2 Cl 2 Extract with a mixed solvent of saturated saline to obtain an organic phase, then dry the organic phase with anhydrous magnesium sulfate, filter, and settle with ice anhydrous ether three times, and after filtration, polyethylene glycol monomethanol containing terminal alkyne groups is obtained. Ether (500 g / mol);

[0043] Step 2: Take 0.02mL of sodium hypochlorite solution and dissolve it in 1000mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com