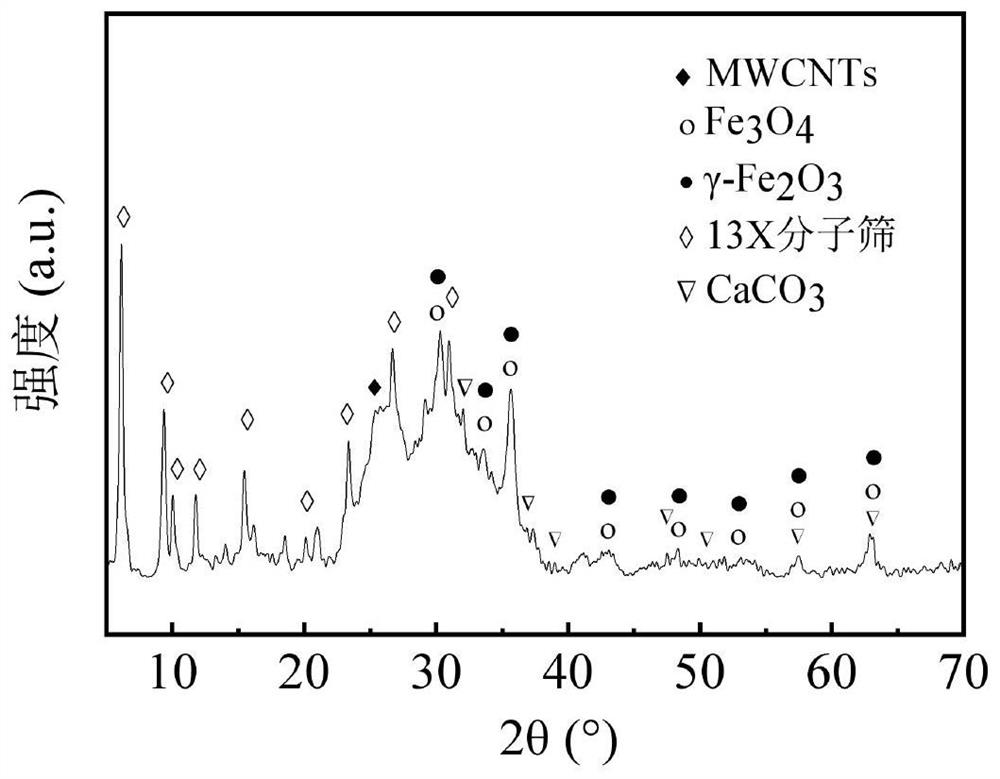

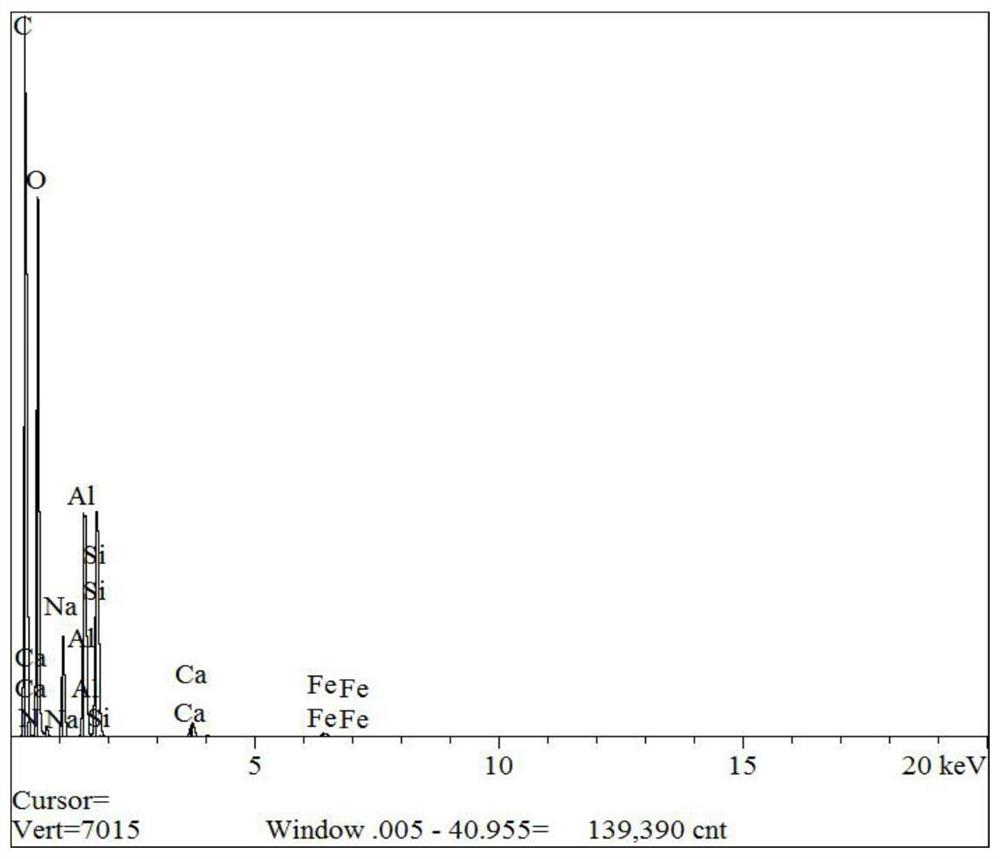

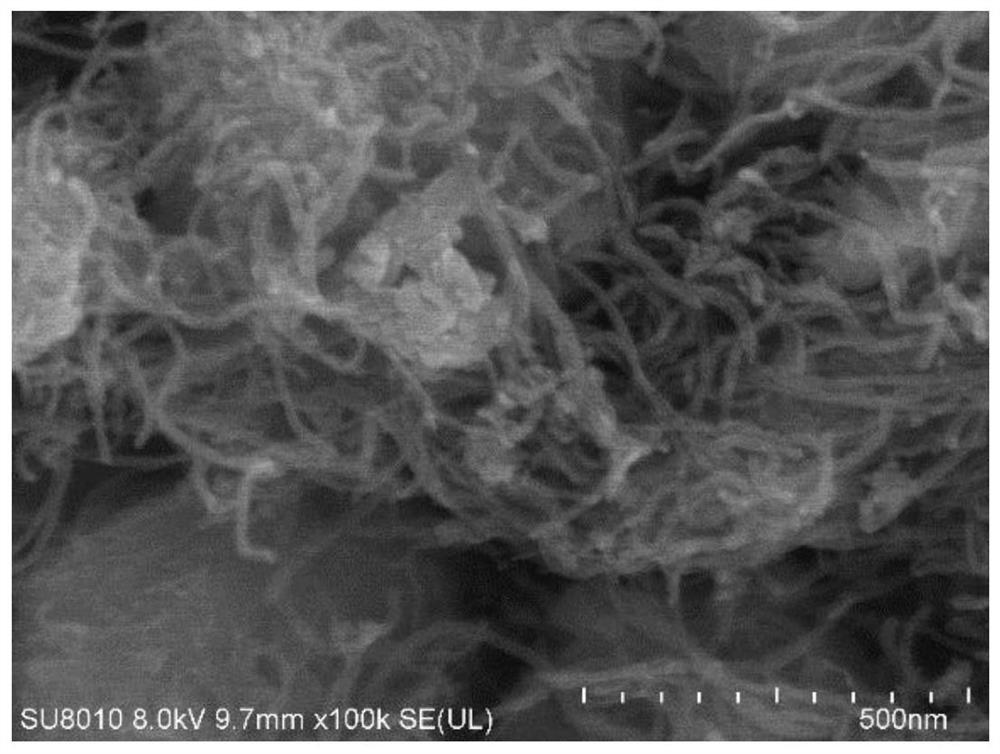

A kind of magnetic carbon nanotube composite material doped with molecular sieve and its preparation method and application

A technology of magnetic carbon nanotubes and composite materials, which is applied in the field of nanomaterials, can solve problems such as the difficulty of separating carbon nanotubes from water, and achieve the effects of repeated use, high removal rate, and resolution of separation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1.① Weigh 0.5000g of carbon nanotubes, suspend them in 125mL of distilled water, and put the suspension under ultrasonic frequency of 45KHz and power of 0.4W / cm 2 Under the conditions, ultrasonic dispersion was carried out for 15 minutes; according to carbon nanotubes and Fe 3 o 4 The mass ratio is 5:2, the molar ratio of ferrous iron to ferric iron (Fe 2+ / Fe 3+ ) is 1:1.43, respectively weigh ferrous ammonium sulfate and ferric ammonium sulfate. Dissolve the weighed ferric ammonium sulfate in 75mL of distilled water, and heat the solution in a constant temperature water bath at 60°C; weigh 0.5000g of anhydrous calcium chloride. Dissolve the weighed anhydrous calcium chloride in 75mL of distilled water, and heat the solution in a constant temperature water bath at 60°C;

[0045] ② According to anhydrous Na 2 CO 3 Prepare a mixed alkali solution with NaOH at a molar ratio of 5:3, and heat it in a constant temperature water bath at 60°C;

[0046] ③Heating the soni...

Embodiment 2

[0056] The difference from Example 1 is that: in step 2, according to the mass ratio of magnetic carbon nanotubes, sodium metaaluminate and sodium silicate to 3:8:80, respectively weigh magnetic carbon nanotubes, sodium metaaluminate and silicic acid Sodium: Dissolve sodium metaaluminate in 10mL of distilled water, add magnetic carbon nanotubes into the sodium metaaluminate solution, and place the mixed suspension in a water bath with a stirring speed of 100r / min under magnetic stirring conditions and heat to 60°C .

[0057] ② Prepare 250 mL of 2 mol / L sodium hydroxide solution; then add sodium silicate to the sodium hydroxide solution, and add 50 mL of distilled water to completely dissolve the sodium silicate.

[0058] ③Keep the constant temperature at 60°C and stir at 100r / min, and slowly titrate with the mixed solution of sodium silicate and sodium hydroxide in ①in the mixed suspension of magnetic carbon nanotubes and sodium metaaluminate. At this temperature, the reactio...

Embodiment 3

[0062] The difference from Example 1 is that: in step 2, according to the mass ratio of magnetic carbon nanotubes to sodium metaaluminate and sodium silicate as 3:6:60, respectively weigh magnetic carbon nanotubes, sodium metaaluminate and silicic acid Sodium: Dissolve sodium metaaluminate in 10mL of distilled water, add magnetic carbon nanotubes to the sodium metaaluminate solution, and place the mixed suspension in a water bath with a stirring speed of 200r / min under magnetic stirring conditions and heat to 30°C .

[0063] ② Prepare 250 mL of 2 mol / L sodium hydroxide solution; then add sodium silicate to the sodium hydroxide solution, and add 50 mL of distilled water to completely dissolve the sodium silicate.

[0064] ③Keep the constant temperature at 30°C and stir at 200r / min, slowly titrate with the mixed solution of sodium silicate and sodium hydroxide in ①in the mixed suspension of magnetic carbon nanotubes and sodium metaaluminate, after the titration is completed At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com