Method used for preparing mesoporous carbon taking chitosan oligosaccharide as carbon nitrogen source

A technology of chitosan oligosaccharide and mesoporous carbon, which is applied in the field of preparation of mesoporous carbon, can solve the problems of messy and wide distribution of mesoporous carbon pore size, and achieve the effects of environmental friendliness, narrow pore size distribution and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

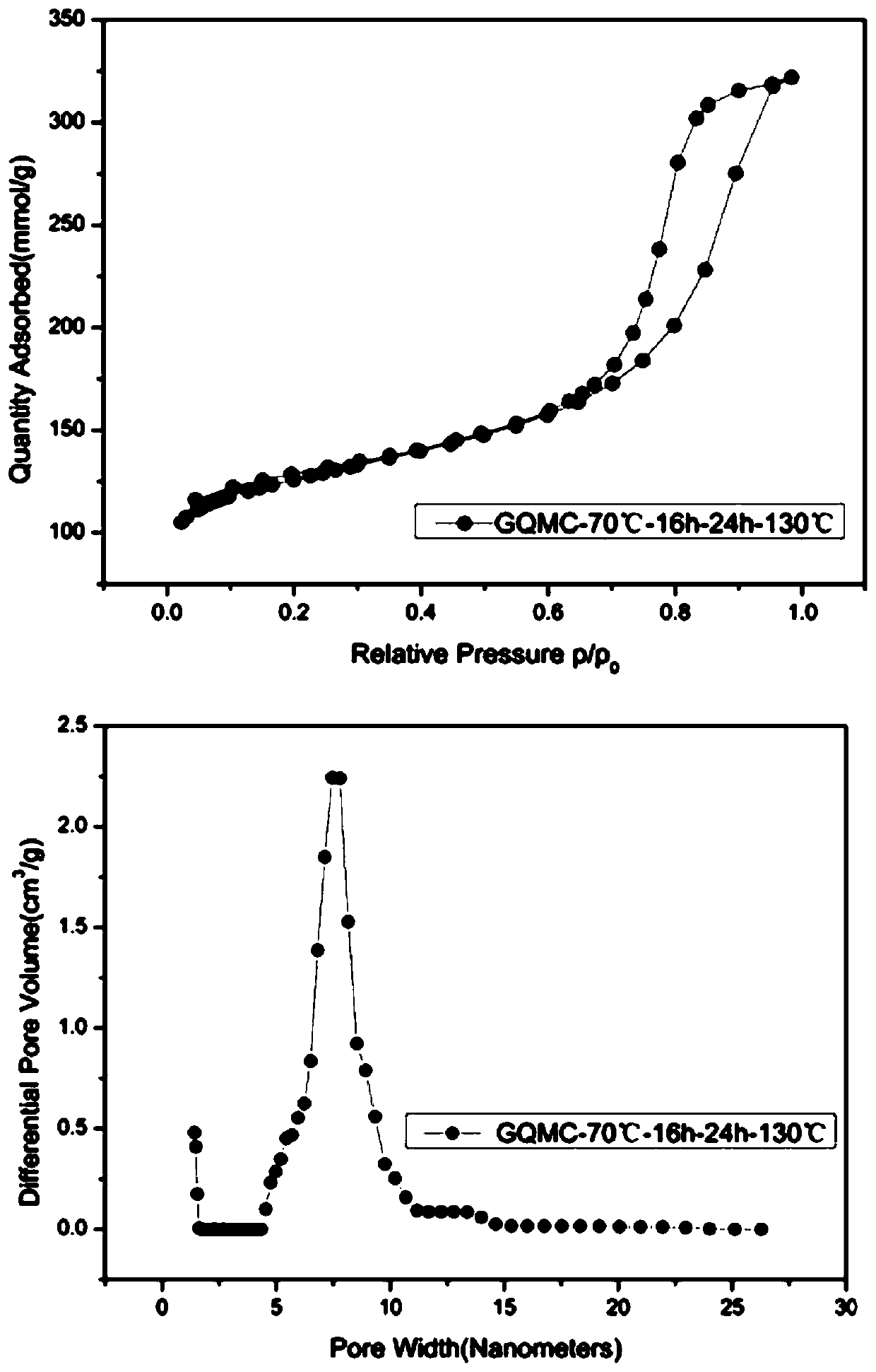

[0034] Embodiment 1: a kind of method for preparing mesoporous carbon with chitosan oligosaccharide as carbon and nitrogen source, the steps are as follows:

[0035] 1) Take polymer nonionic surfactant F127 and put it into water at a mass concentration of 2.2%, and stir in an oil bath at 70°C for 1 hour to obtain solution A;

[0036] 2) Take chitosan oligosaccharide and put it into water at a mass concentration of 6.7%, stir in an oil bath at 70°C for 1 hour, add glyoxal during the stirring process, the mass ratio of glyoxal to water is 2:15, and obtain solution B;

[0037] 3) Add solution B to solution A to obtain solution C, and continue to stir solution C in an oil bath at 70° C. for 2 hours to obtain solution D;

[0038] 4) Add 1.5 times the amount of water to solution D for dilution, and continue to stir and react the diluted solution at 70°C for 16 hours to obtain solution E;

[0039] 5) After the solution E was cooled to room temperature, it was transferred into a hydr...

Embodiment 2

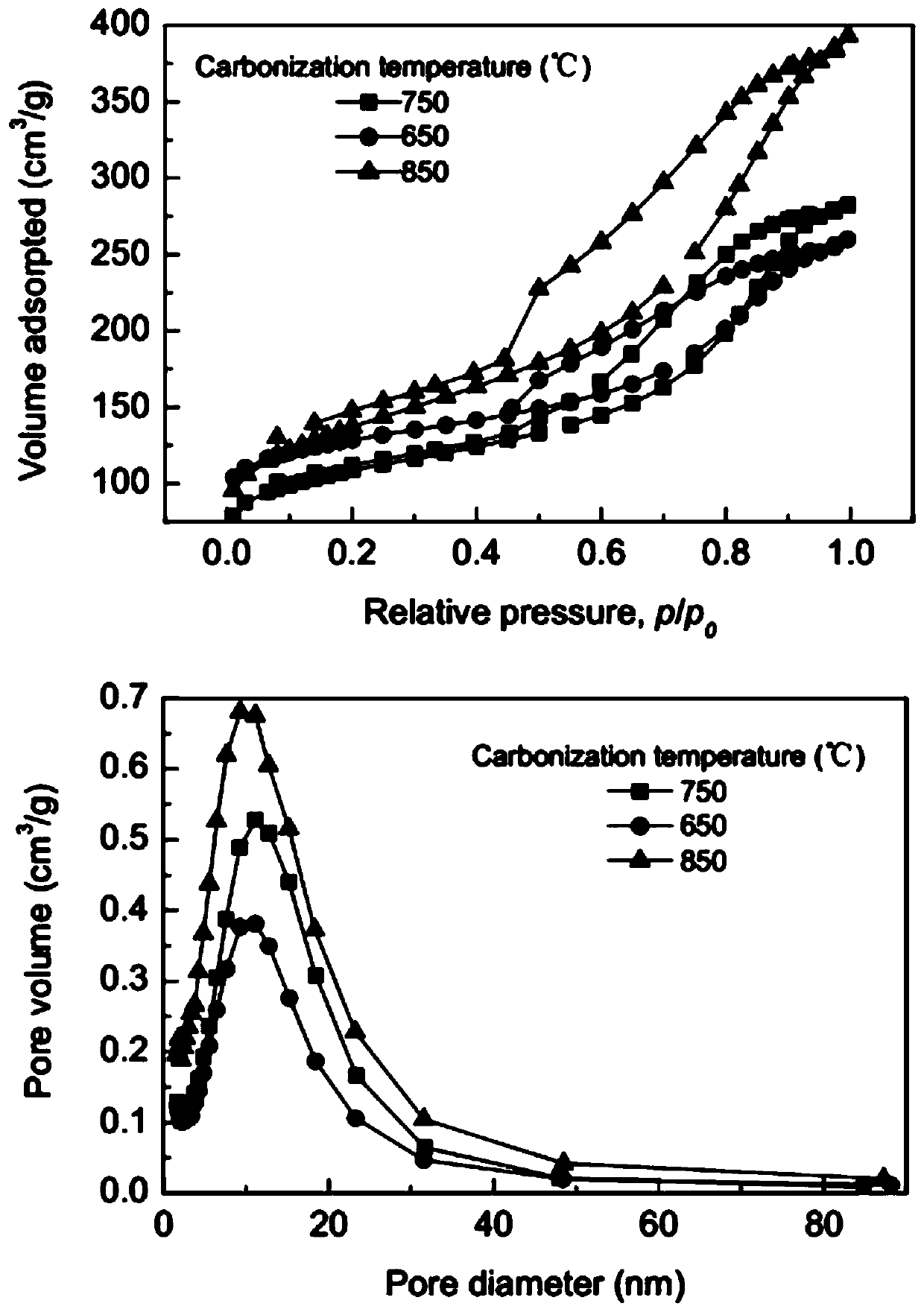

[0042] Embodiment 2: a kind of method that uses chitosan oligosaccharide as carbon and nitrogen source to prepare mesoporous carbon, the steps are as follows:

[0043] 1) Take polymer nonionic surfactant F127 and put it into water at a mass concentration of 2%, and stir in an oil bath at 60°C for 1.5 hours to obtain solution A;

[0044] 2) Take chitosan oligosaccharide and put it into water at a concentration of 5%, stir the oil bath at 60°C for 1.5h, add glyoxal during the stirring process, the mass ratio of glyoxal to water is 1:15, and obtain solution B;

[0045] 3) Add solution B to solution A to obtain solution C, and continue to stir solution C in an oil bath at 60°C for 12.5 hours to obtain solution D;

[0046] 4) Add 1 times the amount of water to solution D for dilution, and continue to stir and react the diluted solution at 60°C for 20 hours to obtain solution E;

[0047] 5) After cooling solution E to room temperature, transfer it into a hydrothermal reaction kettl...

Embodiment 3

[0050] Embodiment 3: a kind of method that uses chitosan oligosaccharide as carbon and nitrogen source to prepare mesoporous carbon, the steps are as follows:

[0051]1) Take polymer nonionic surfactant F127 and put it into water at a mass concentration of 3%, and stir in an oil bath at 80°C for 0.5h to obtain solution A;

[0052] 2) Take chitosan oligosaccharide and put it into water at a concentration of 8%, stir the oil bath at 80°C for 0.5h, add glyoxal during the stirring process, the mass ratio of glyoxal to water is 1:5, and obtain solution B;

[0053] 3) Add solution B to solution A to obtain solution C, and continue stirring solution C in an oil bath at 80° C. for 1.5 h to obtain solution D;

[0054] 4) Add 2 times the amount of water to solution D for dilution, and continue to stir and react the diluted solution at 80°C for 10 hours to obtain solution E;

[0055] 5) After cooling solution E to room temperature, transfer it into a hydrothermal reaction kettle, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com