Carbon-based slow-release fertilizer coated with bio-oil film

A bio-oil and bio-char technology, applied in layered/coated fertilizers, nitrogen fertilizers, potash fertilizers, etc., can solve the problem of not fully exerting the slow-release ability of biochar, limited slow-release ability of carbon-based slow-release fertilizers, and increasing crop absorption, etc. problems, to achieve the effect of improving nutrient utilization, reducing nutrient loss, and prolonging fertilizer efficiency period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A kind of oil-coated carbon-based slow-release fertilizer

[0028] It comprises 80-120 parts by mass of biochar, 15-22 parts by mass of potassium nitrate, 4-9 parts by mass of potassium dihydrogen phosphate, 1-3 parts by mass of potassium chloride, and 60-90 parts by mass of bio-oil.

[0029] Both the biochar and bio-oil come from the pyrolysis process of wheat straw, which has an yield of about 600kg per mu, and contains rich N, P, K nutrients and good fiber structure.

[0030] In the pyrolysis process, the initial pyrolysis temperature is set to 20°C, the heating rate is 20°C / min, the target temperature is 400°C, the residence time at the target temperature is 2h, and the pyrolysis inert gas is CO 2 , N 2 Or water vapor, the gas flow rate is 20ml / min, so that the straw is pyrolyzed to prepare initial biochar and ground through a 1mm sieve to make the particle size uniform.

Embodiment 2

[0031] Embodiment 2: A combination of oil-coated carbon-based slow-release fertilizers. The composition of the new carbon-based slow-release fertilizer fertilizer body is composed of the above-mentioned components, and is wrapped with bio-oil film after absorbing nutrients with biochar form combination.

Embodiment 3

[0032] Embodiment 3: a kind of preparation process of oil-coated carbon-based slow-release fertilizer, the final product of this process is the slow-release fertilizer body described in Example 2, which includes:

[0033] (1) Collect wheat straw and dry it at 60°C for pretreatment;

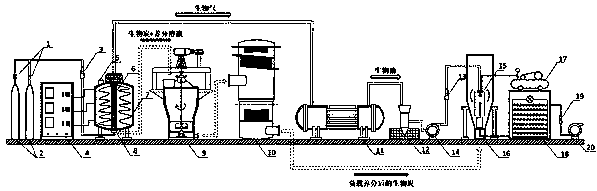

[0034] (2) Add the dried straw into the pyrolysis tube 7 from the feeding port 5, set the initial pyrolysis temperature to 20°C, the heating rate to 20°C / min, and the target temperature to 400°C through the three-stage temperature control system 4. The temperature residence time is 2h, open the gas valve 1, pass the N 2 or CO 2 Gas cylinder 2 feeds inert gas CO into pyrolysis tube 6 2 or N 2 , the gas flow rate is controlled to 20ml / min by the flow meter 3, so that the straw is pyrolyzed to prepare initial biochar and ground through a 1mm sieve to make the particle size uniform;

[0035] (3) Combine the initial biochar and KH 2 PO 4 and KNO 3 The solution is mixed in a certain ratio, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com