Preparation method of hyperbranched zwitterionic polyacrylamide and application of hyperbranched zwitterionic polyacrylamide in oilfield exploitation

A technology of polyacrylamide and zwitterion, which is applied in the field of polyacrylamide polymer synthesis to achieve improved solubility, high rheology, and improved salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

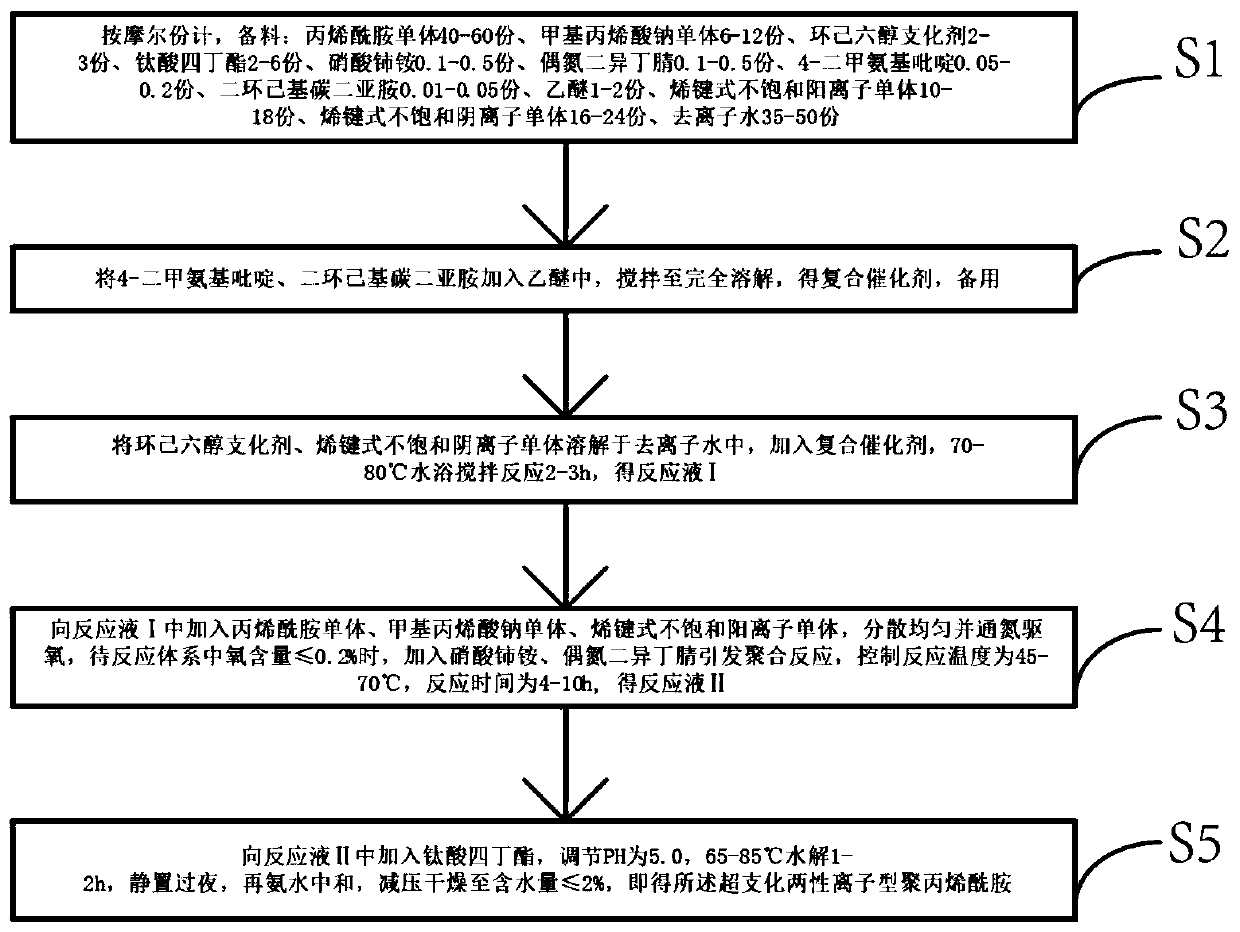

Method used

Image

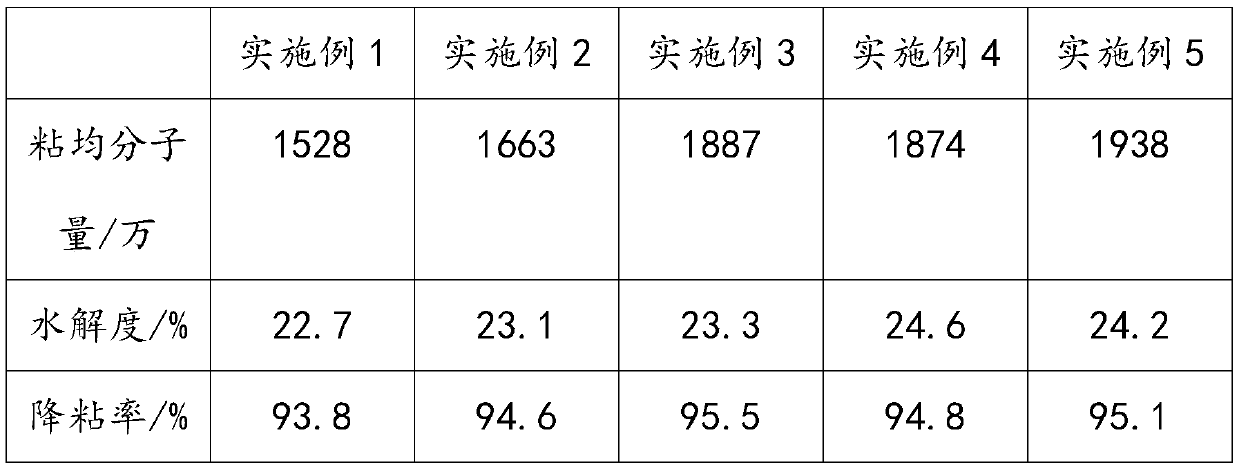

Examples

Embodiment 1

[0027] A preparation method of hyperbranched zwitterionic polyacrylamide, comprising the following steps:

[0028] S1: in molar parts, raw materials: 40 parts of acrylamide monomer, 6 parts of sodium methacrylate monomer, 2 parts of cyclohexane branching agent, 2 parts of tetrabutyl titanate, 0.1 part of ammonium cerium nitrate, 0.1 part of nitrogen bisisobutyronitrile, 0.05 part of 4-dimethylaminopyridine, 0.01 part of dicyclohexylcarbodiimide, 1 part of ether, 10 parts of methacryloyloxyethyltrimethylammonium chloride, 2-propene Amide-2-methylpropanesulfonic acid 16 parts, deionized water 35 parts;

[0029] S2: Add 4-dimethylaminopyridine and dicyclohexylcarbodiimide into diethyl ether, and stir until completely dissolved to obtain a composite catalyst, which is set aside;

[0030] S3: Dissolving the cyclohexaol branching agent and 2-acrylamide-2-methylpropanesulfonic acid in deionized water, adding the composite catalyst, stirring and reacting in a water bath at 70°C for 2...

Embodiment 2

[0034] A preparation method of hyperbranched zwitterionic polyacrylamide, comprising the following steps:

[0035] S1: In molar parts, raw materials: 50 parts of acrylamide monomer, 9 parts of sodium methacrylate monomer, 2.5 parts of cyclohexane branching agent, 4 parts of tetrabutyl titanate, 0.3 parts of ammonium cerium nitrate, 0.3 parts of nitrogen diisobutyronitrile, 0.15 parts of 4-dimethylaminopyridine, 0.03 parts of dicyclohexylcarbodiimide, 1.5 parts of ether, 14 parts of dimethyl diallyl ammonium chloride, 20 parts of maleic anhydride part, 45 parts of deionized water;

[0036] S2: Add 4-dimethylaminopyridine and dicyclohexylcarbodiimide into diethyl ether, and stir until completely dissolved to obtain a composite catalyst, which is set aside;

[0037] S3: Dissolving the cyclohexyl hexaol branching agent and the ethylenically unsaturated anionic monomer in deionized water, adding the composite catalyst, stirring and reacting in a water bath at 75°C for 2.5 hours, t...

Embodiment 3

[0041] A preparation method of hyperbranched zwitterionic polyacrylamide, comprising the following steps:

[0042] S1: in parts by mole, raw materials: 60 parts of acrylamide monomer, 12 parts of sodium methacrylate monomer, 3 parts of cyclohexyl alcohol branching agent, 6 parts of tetrabutyl titanate, 0.5 part of cerium ammonium nitrate, 0.5 parts of nitrogen bisisobutyronitrile, 0.2 parts of 4-dimethylaminopyridine, 0.05 parts of dicyclohexylcarbodiimide, 2 parts of diethyl ether, 18 parts of acryloyloxyethyltrimethylammonium chloride, β-itaconic acid 24 parts of monomethyl ester, 50 parts of deionized water;

[0043] S2: Add 4-dimethylaminopyridine and dicyclohexylcarbodiimide into diethyl ether, and stir until completely dissolved to obtain a composite catalyst, which is set aside;

[0044]S3: dissolving the cyclohexyl alcohol branching agent and β-monomethyl itaconate in deionized water, adding the composite catalyst, stirring and reacting in a water bath at 80°C for 3 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com