Beta-silicon carbide crystal whisker preparation method

A technology of silicon carbide whiskers and silicon sources, which is applied in the field of preparation of β-silicon carbide whiskers, can solve the problems of low reactivity of raw materials, decline in mechanical properties, high reaction temperature, etc., and achieve resource utilization and high-value utilization, Low cost, reduced reaction time and temperature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

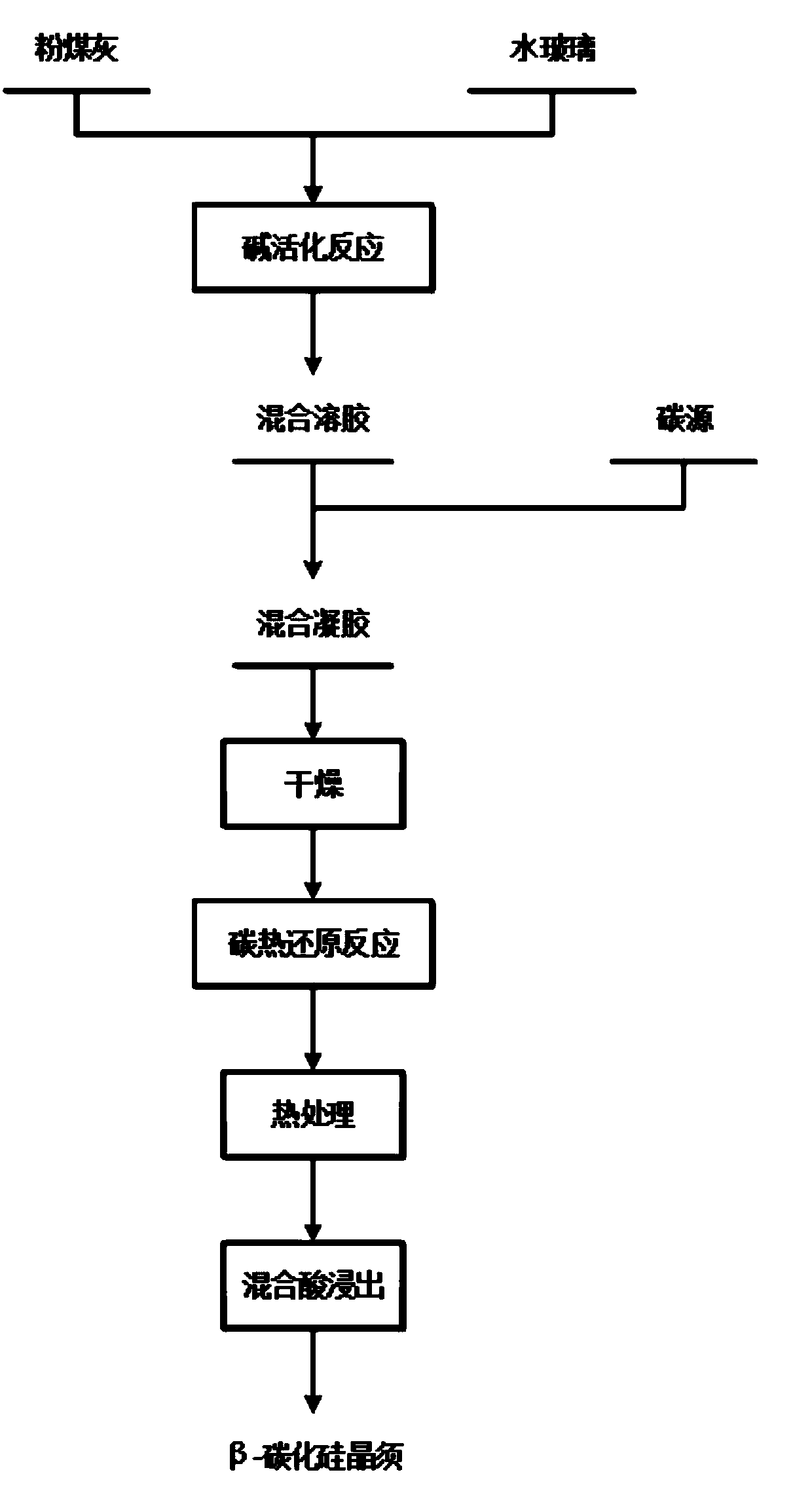

[0053] The present embodiment provides the preparation method of β-silicon carbide whisker, figure 1 The process flow chart for preparing β-silicon carbide whiskers in this example.

[0054] The silicon source that contains silicate that present embodiment adopts is the fly ash that a thermal power plant of Xilinguole League, Inner Mongolia Autonomous Region provides, and its main component is as shown in table 1; Water glass is sodium silicate aqueous solution; Carbon source is activated carbon; The solution is a mixed acid solution obtained by mixing a hydrofluoric acid solution with a mass fraction of 40% and a hydrochloric acid solution with a mass fraction of 37% at a volume ratio of 1:1.

[0055] The preparation method is as follows:

[0056] (1) Mix fly ash and sodium silicate aqueous solution according to the mass ratio of 1:10, and react and activate at 25°C for 5 hours to obtain a mixed sol; among them, SiO in the silicon source 2 The content of water glass is 47.0...

Embodiment 2

[0062] This example provides a method for preparing β-silicon carbide whiskers.

[0063] The silicon source that contains silicate that present embodiment adopts is the fly ash that a thermal power plant in Shuozhou City, Shanxi Province provides, and its main component is as shown in table 1; Water glass is sodium silicate aqueous solution; Carbon source is carbon black The acid solution is a mixed acid solution obtained by mixing a hydrofluoric acid solution with a mass fraction of 40% and a hydrochloric acid solution with a mass fraction of 37% in a volume ratio of 5:1.

[0064] The preparation method is as follows:

[0065] (1) Mix fly ash and sodium silicate aqueous solution according to the mass ratio of 1:3, and react and activate at 90°C for 1 hour to obtain a mixed sol; among them, SiO in the silicon source 2 The content of water glass is 59.04wt%, the modulus of water glass is 2.4, and the density is 1.36g / cm 3 .

[0066] (2) Add carbon black to the mixed sol obta...

Embodiment 3

[0071] This example provides a method for preparing β-silicon carbide whiskers.

[0072] The silicon source that contains silicate that present embodiment adopts is the fly ash that certain thermal power plant of Tianjin provides, and its main component is as shown in table 1; Water glass is sodium silicate aqueous solution; Carbon source is carbon black; Acid solution It is a mixed acid solution obtained by mixing a hydrofluoric acid solution with a mass fraction of 40% and a hydrochloric acid solution with a mass fraction of 37% at a volume ratio of 2:1.

[0073] The preparation method is as follows:

[0074] (1) Mix fly ash and sodium silicate aqueous solution according to the mass ratio of 1:8, and react and activate at 10°C for 48 hours to obtain a mixed sol; among them, SiO in the silicon source 2 The content of water glass is 47.04wt%, the modulus of water glass is 2.8, and the density is 1.45g / cm 3 .

[0075] (2) Add carbon black to the mixed sol obtained in step (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com