Modified TM-LDH nano material, preparation method and application thereof

A nano-material and modification technology, which is applied in chemical instruments and methods, catalyst activation/preparation, electrodes, etc., can solve the problems of lack of water splitting catalysts, etc., and achieve the effects of reducing Tafel slope, reducing cost, and reducing overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

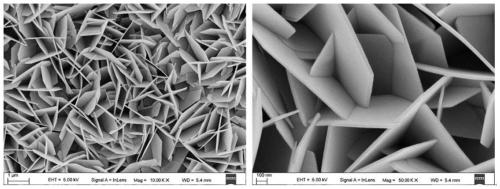

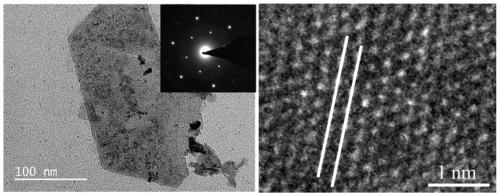

[0039] Example 1: SAV-NiCu with single-atom vacancy defects x Preparation and Characterization of LDH Nanosheet Self-supporting Electrode

[0040] 1.1 Preparation of NiCu LDH nanosheet self-supporting electrode

[0041] NiCu LDH nanosheets were grown on nickel foam by hydrothermal method to prepare NiCu LDH nanosheet self-supporting electrodes. The specific operation is as follows:

[0042] A piece of nickel foam (2 cm x 3 cm) was immersed in 1M HCl solution for 10 min to remove surface oxides, then washed several times with deionized water and ethanol, and dried in an oven at 60 °C for later use.

[0043] Add x mL of 10mM nickel nitrate (Ni(NO 3 ) 2 ) aqueous solution and y mL of 5mM copper nitrate (Cu(NO 3 ) 2 ) aqueous solution, and then add 87mL of deionized water. The Ni / Cu molar ratio in the product is adjusted by adjusting the ratio of x and y, wherein x+y=2, preferably x=y=1. Then, under magnetic stirring, 1 mL of 100 mM aqueous urea solution was added to the b...

Embodiment 2

[0054] Example 2: SAV-NiFeCu with single-atom vacancy defects x Preparation and Characterization of LDH Nanosheets

[0055] 2.1 Preparation of NiFeCu LDH nanosheets

[0056] NiFeCu LDH nanosheets were synthesized by hydrothermal method, the specific operation is as follows.

[0057] Add x mL of 1M ferric chloride (FeCl 3 ) aqueous solution, y mL of 1M nickel chloride (NiCl 2 ) aqueous solution and zmL of 1M copper chloride (CuCl 2 ) aqueous solution, by adjusting the ratio of x, y and z to adjust the Fe / Ni / Cu molar ratio in the product, wherein x+y+z=1.45, preferably x=z=0.145, y=1.16. Another 71 mL of deionized water was added. Then, under magnetic stirring, 5.6 mL of 0.5 M urea aqueous solution and 2 mL of 0.01 M trisodium citrate aqueous solution were added to the beaker. Then the resulting mixed solution was transferred into a 100 mL polytetrafluoroethylene-lined stainless steel autoclave, and after sealing, a hydrothermal reaction was performed in an oven at 180 °C...

Embodiment 3

[0065] Example 3: SAV-NiFe with single-atom vacancy defects x Preparation and Characterization of LDH Nanosheet Self-supporting Electrode

[0066] 1.1 NiFe x Preparation of LDH Nanosheet Self-supporting Electrode

[0067] Growth of NiFe on Nickel Foam by Hydrothermal Method x LDH nanosheets, prepared NiFe x LDH nanosheet self-supporting electrode, the specific operation is as follows:

[0068] A piece of nickel foam (2 cm x 3 cm) was immersed in 1M HCl solution for 10 min to remove surface oxides, then washed several times with deionized water and ethanol, and dried in an oven at 60 °C for later use.

[0069] Add x mL of 10mM nickel nitrate (Ni(NO 3 ) 2 ) aqueous solution and y mL of 5mM copper nitrate (Fe(NO 3 ) 3 ) aqueous solution, and then add 87mL of deionized water. The Ni / Fe molar ratio in the product is adjusted by adjusting the ratio of x to y, wherein x+y=2, preferably x=y=1. Then, under magnetic stirring, 1 mL of 100 mM aqueous urea solution was added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com