Device and method for preparing graphite by Zn/Fe flame sealed-tube method

A tube sealing method, graphite technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as affecting the efficiency of graphite preparation, time-consuming, etc., to improve practical performance, avoid atmospheric leakage, and improve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0099] Filled with CO 2 Before the preparation of raw materials, the present invention preferably CO 2 The oxidizing agent in the preparation raw material is subjected to decarbonization treatment, and the decarbonization treatment is preferably kept at 800-950°C, more preferably at 850-930°C, and more preferably at 900°C; the holding time is preferably 1.5-2.5h, more preferably 1.7-2.2h, more preferably 2h.

[0100] The CO of the present invention 2 The methods of filling, vacuuming and flame sealing of the prepared raw materials are described in Example 1.

[0101] In the present invention, for CO 2When the preparation raw materials are heated, the heating temperature is preferably 840-860°C, more preferably 845-855°C, and more preferably 850°C, and the heating time (ie reaction time) is preferably ≥12h, more preferably 12-850°C. 15h, more preferably 13-14h. The heating in the present invention is preferably carried out in a muffle furnace.

[0102] When producing CO ...

Embodiment 1

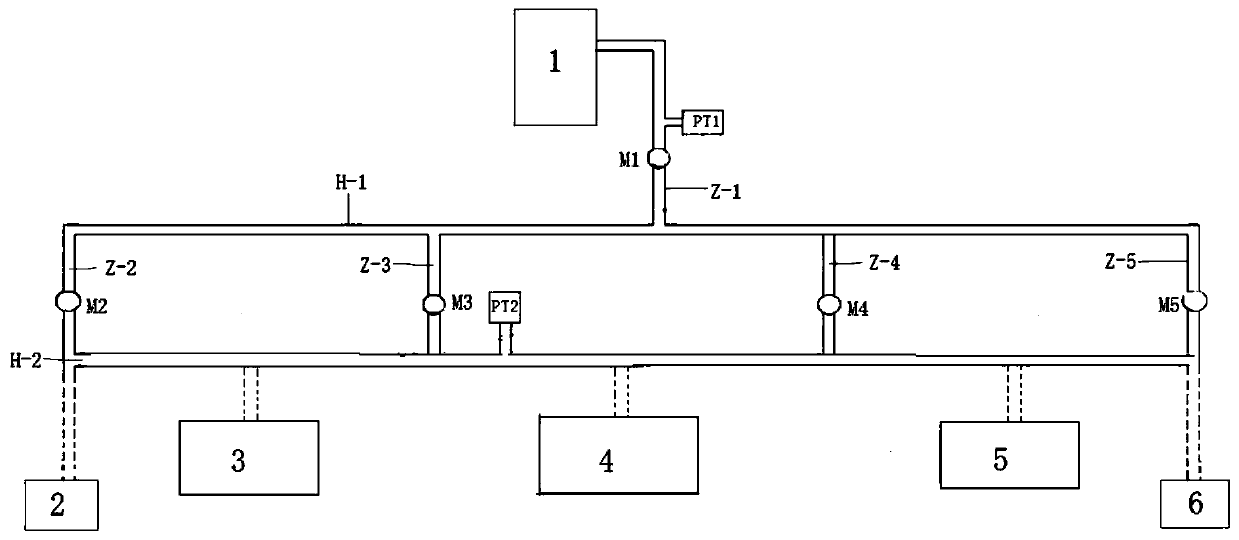

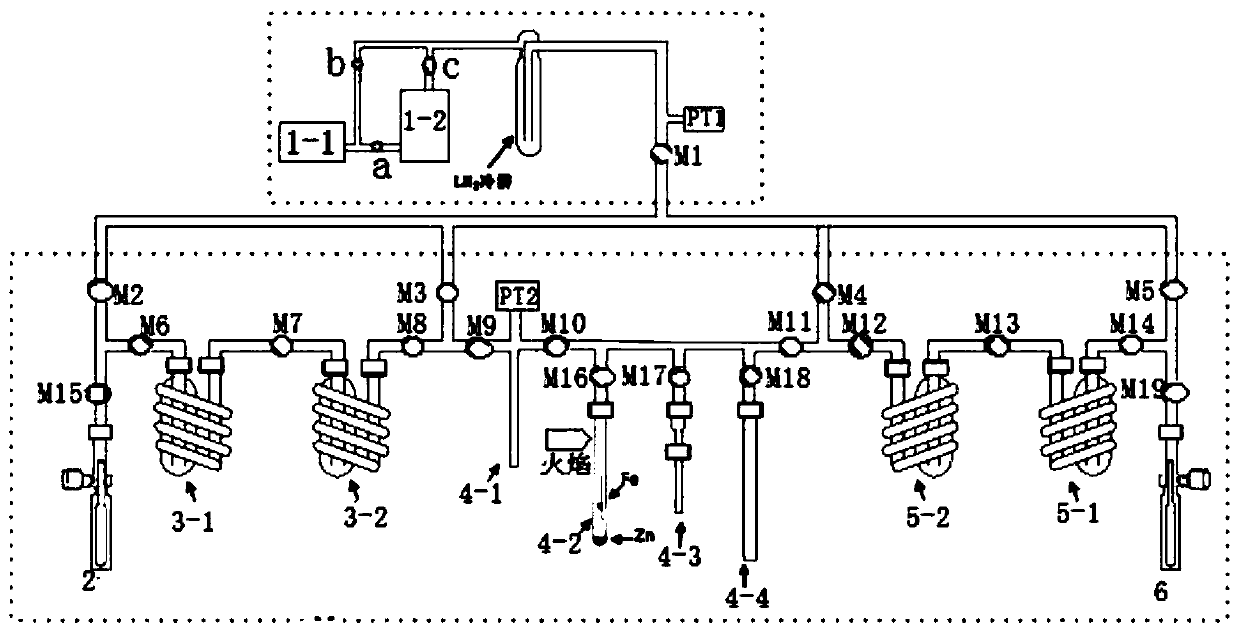

[0114] according to Figure 1~2 The structural construction device shown: the main pipeline Z-1 is composed of a glass-welded high-vacuum glass valve (Kimble, USA) with an outer diameter of 9.5mm, and the detachable parts are connected by Ultra-Torr stainless steel joints (Swagelok, USA);

[0115] Vacuum system 1 is supported by a Hicube 80 vacuum pump unit and a composite vacuum gauge PKR 251 (Pfeiffer Vacuum, Germany); the backing pump of the turbomolecular pump is an oil-free diaphragm pump;

[0116] First CO 2 Preparation unit 2, the second CO 2 Preparation unit 6, the first CO 2 Purification unit 3, the second CO 2 Purification unit 5, CO 2 The sampling unit consists of 4, where CO 2 Sampling unit 4 consists of sequentially arranged CO 2 Constant volume tube 4-1, double-layer casing reactor 4-2, 13 The C sampling tube 4-3 and the backup sample sampling tube 4-4 are composed, and the setting method is fixed at the connecting nozzle of the connecting pipe H-2 through...

Embodiment 2

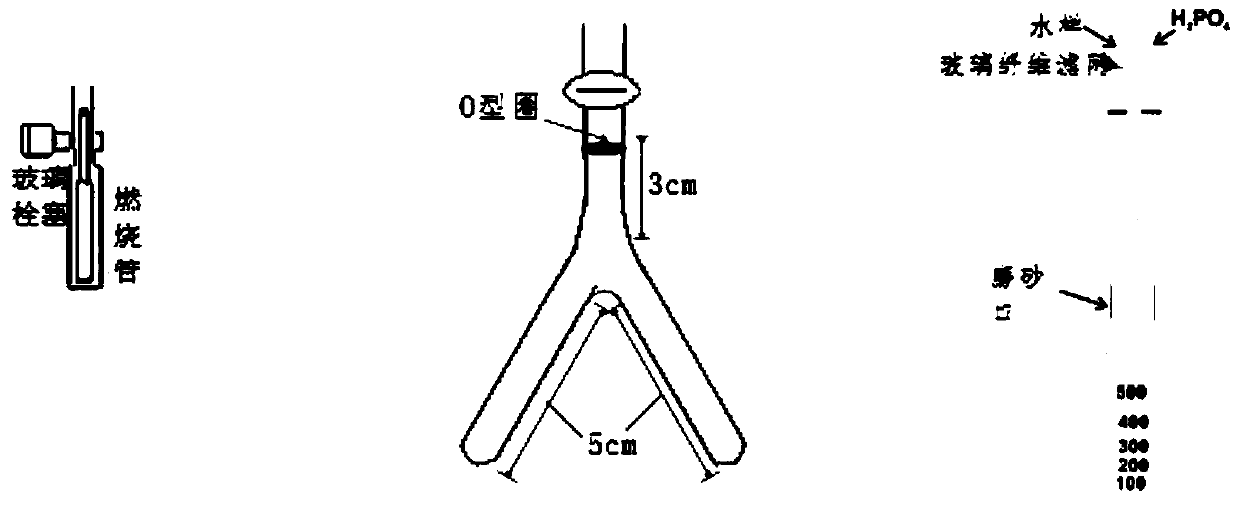

[0138] Same as Example 1, the difference is that the inorganic carbon sample is used in a Y-type acid hydrolysis tube to carry out acid hydrolysis reaction with 6mL phosphoric acid (85% V / V, Tianjin Kermel Chemical Reagent) to generate CO 2 . The inorganic carbon sample used in this example is calcite (IHEG Cal, inorganic carbon). Calcite crystals were collected from the Yangliugang Formation (Middle Cambrian ~ 520 Ma), with high crystallinity, pure white and no impurities. The crystals were crushed in an agate mortar and then soaked in 1% (V / V) hydrochloric acid for 4 hours to remove the influence of surface inorganic carbon. After washing and drying with deionized water, they were used for the preparation of graphite and the purification and collection of carbon dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com