Liquid phase oxidation method for preparing trimesic acid/trimellitic acid

A technology for trimesic acid and trimellitic acid, which is used in the preparation of carbonyl compounds by oxidation, chemical instruments and methods, preparation of organic compounds, etc., can solve the problem of insufficient contact between oxidant molecules and raw material molecules, insufficient utilization of oxidants, and difficult A large number of problems such as obtaining, to achieve the effect of suitable for large-scale production, improve oxidation capacity, improve miscibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

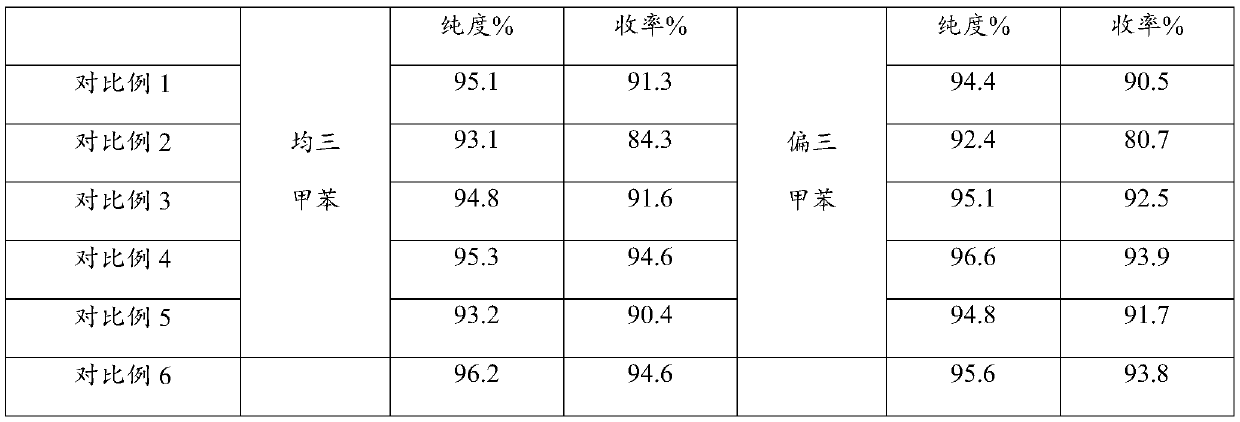

Examples

Embodiment 1

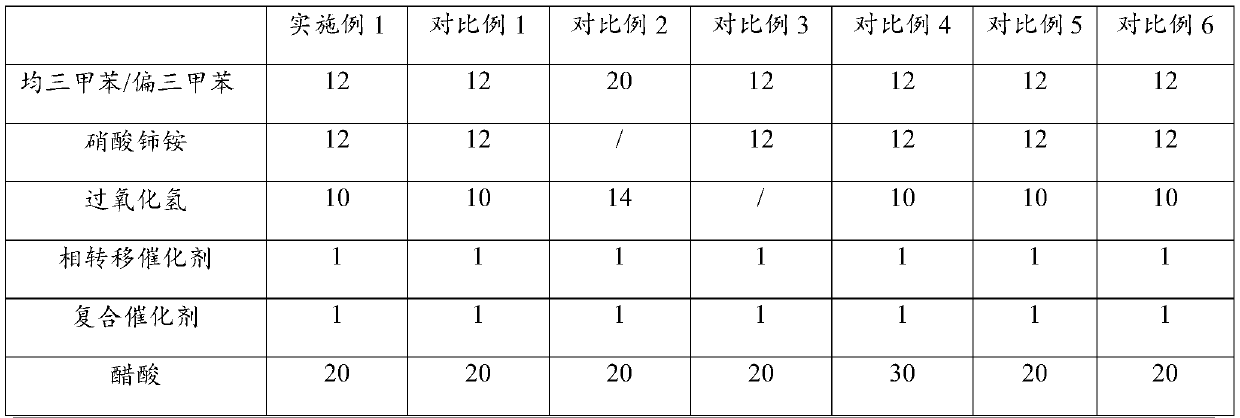

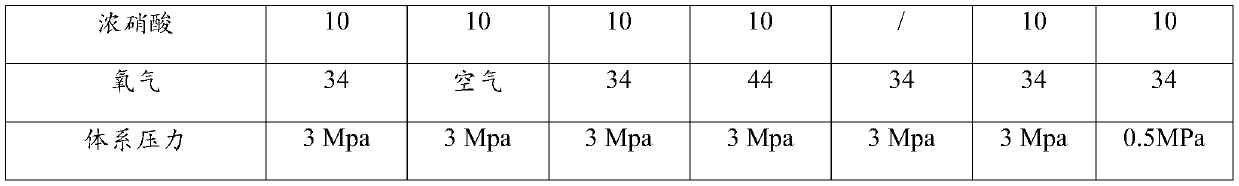

[0042] A method for preparing trimellitic acid / trimellitic acid by a liquid-phase oxidation method comprises the following steps:

[0043] (1) 12mol% mesitylene, 12mol% cerium ammonium nitrate, 10mol% hydrogen peroxide solution and 1mol% phase transfer catalyst are added in the stainless steel autoclave;

[0044] (2) Close the autoclave, start stirring, heat up to 80°C, and fully react for 3 hours;

[0045] (3) Then add 1mol% composite catalyst, 20mol% acetic acid and 10mol% concentrated nitric acid to the above-mentioned mixed material, after fully mixing, heat up to 100°C, add 34mol% oxygen, keep the pressure in the kettle to be 3.0Mpa, heat preservation reaction 6h;

[0046] (4) Cool down to 5 DEG C by cooling to 5 DEG C to carry out cooling crystallization in reactor, open pressure relief valve slowly to remove pressure, suction filtration obtains trimesic acid crude product;

[0047] (5) Add hot water at 100°C to recrystallize the crude product, the mass ratio of hot wa...

Embodiment 2

[0052] In Example 2: the phase transfer catalyst is cyclodextrin; the mass ratio of nickel nitrate and titanium nitrate in the composite catalyst is 1:2; the rest of the raw materials without special instructions are the same as in Example 1, and the following examples are all the same; The pressure is 5.0Mpa,

Embodiment 3

[0053] In Example 3: the mass ratio of nickel nitrate to titanium nitrate is 1:3; the pressure in the kettle is kept at 4.0Mpa;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com