Ru-based hydrogen evolution catalyst, and preparation method and application thereof

A catalyst and hydrogen evolution technology, applied in the field of electrochemistry, to achieve the effects of simple process, less pollution to the environment, and simple post-treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method for a Ru-based hydrogen evolution catalyst, comprising the steps of:

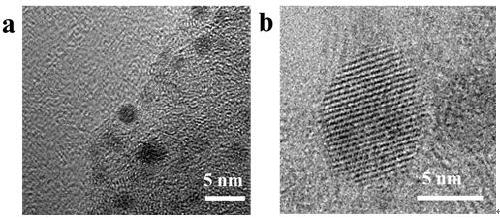

[0039] 1) Mix 1.54mL phytic acid, 0.74mL aniline, and 3mL p-phenylenediamine (p-phenylenediamine is dissolved in water, the concentration is 10mg / mL, the same below) and mix and stir for 15min, add 8mL of 237.75mg / mL ammonium persulfate The aqueous solution was stirred evenly, and reacted in an ice-water bath at 0~5°C for 1 hour, transferred to the reactor, and reacted at 180°C for 3 hours. After the reaction was completed, it was naturally cooled to room temperature, washed and dried to obtain polyaniline fibers; 2) the step 1 ) The obtained polyaniline fibers were heated to 750°C under an inert atmosphere, kept at a temperature of 4 hours, and then naturally cooled to room temperature. The obtained black product was nitrogen-containing carbon fibers in the form of nano-networks;

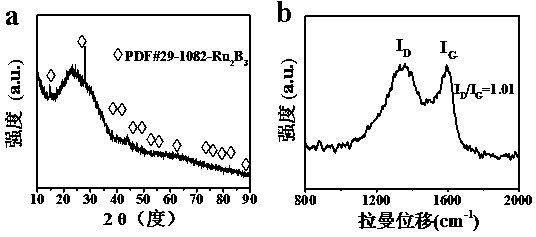

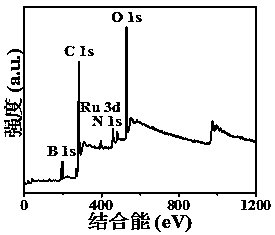

[0040] 3) Take the mass ratio of nitrogen-containing carbon fiber, melamine, boric acid and ruthen...

Embodiment 2

[0052] A preparation method for a Ru-based hydrogen evolution catalyst, comprising the steps of:

[0053] 1) Mix and stir 1.54mL phytic acid, 0.74mL aniline, and 3mL p-phenylenediamine (10mg / mL) for 15min, add 8mL of 237.75mg / mL ammonium persulfate aqueous solution and stir evenly, react in an ice-water bath at 0~5℃ for 1h, transfer Put it into the reaction kettle and react at 180°C for 3 hours. After the reaction, naturally cool to room temperature, wash and dry to obtain polyaniline fibers;

[0054] 2) Heat the dried product obtained in step 1 to 750°C under an inert atmosphere, keep it warm for 4 hours, and then cool it down to room temperature naturally. The obtained black product is nitrogen-containing carbon fiber in the form of a nano-network;

[0055] 3) The mass ratio of nitrogen-containing carbon fiber, melamine, boric acid and ruthenium chloride obtained in step 2) is 3:4:2:1, stirred at room temperature for 5 hours to form a suspension, and the obtained suspension ...

Embodiment 3

[0058] The difference between embodiment 3 and embodiment 2 is that in step 3), the mass ratio of nitrogen-containing carbon fiber, melamine, boric acid and ruthenium chloride is 3:4:6:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com