Cutting pick and preparation method thereof

A pick and intermediate frequency technology, which is applied in the field of parts manufacturing, can solve the problems of limited alloying effect, complicated process, and slow penetration rate of solid penetrating agent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

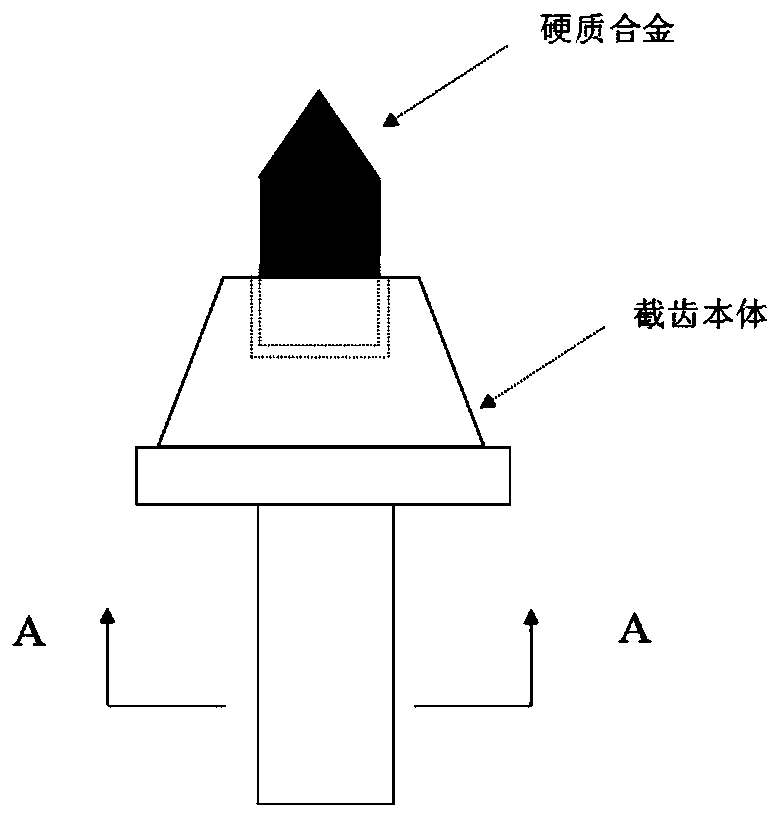

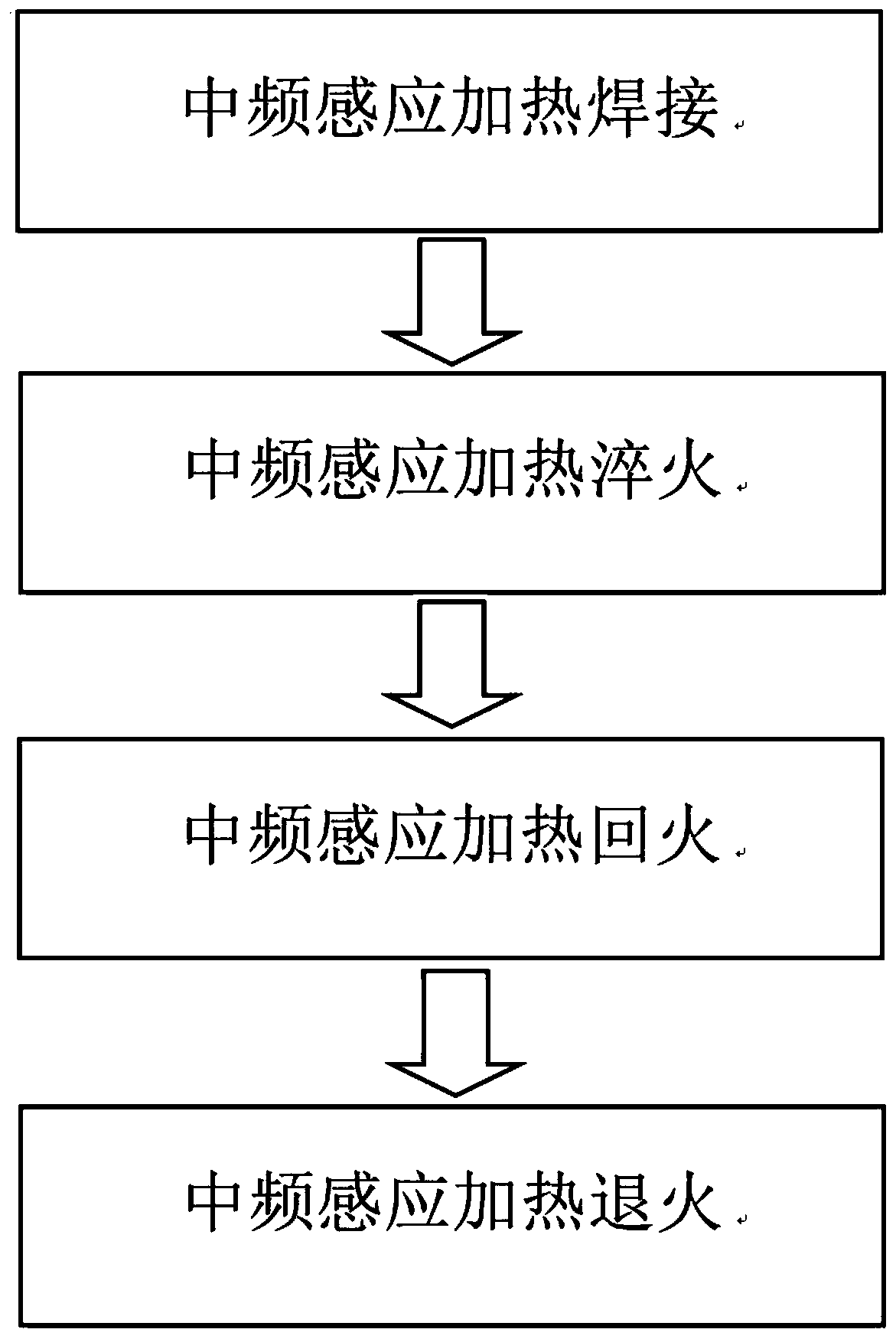

[0025] The invention provides a kind of preparation method of cutting tooth, comprises the following steps:

[0026] The pick body and the hard alloy are welded by medium frequency induction heating to obtain parts;

[0027] The parts are subjected to intermediate frequency induction heating and quenching in sequence to obtain quenched parts;

[0028] performing intermediate frequency induction heating and tempering on the quenched parts and then air cooling to obtain tempered parts;

[0029] The tooth shank of the tempered part is sequentially subjected to intermediate frequency induction heating annealing and air cooling to obtain a pick.

[0030] In the invention, the pick body and the hard alloy are welded by medium-frequency induction heating to obtain parts. In the present invention, the cemented carbide preferably includes cemented carbide with a grade of YG4C, YG8C, ZD30 or ZD15 for geological and mining tools. In the present invention, there is no special limitatio...

Embodiment 1

[0045] The pick adopts 42CrMo as the alloy material of the pick body, and its heat treatment process parameters are: A 1 730°C, A 3 is 800°C and Ms is 310°C. The process steps are as follows: first place the pick on the tooling, make the intermediate frequency induction heating equipment surround the hard alloy head (hard alloy for YG4C geological and mining tools) and the end face of the pick shank to be welded, adjust the intermediate frequency induction between it and the welder The gap between the parts is 20mm, adjust the frequency of the intermediate frequency sensor to 5kHz, keep it for 30s after reaching the temperature, control the initial temperature of the top to 1250°C, the upsetting amount is 4mm, and the welding upsetting is completed within 6s after the heating stops. Then carry out overall induction heating and quenching on the pick, the heating frequency remains unchanged, keep it for 25s after reaching the temperature, spray liquid cooling after induction he...

Embodiment 2

[0047] The pick adopts 35CrMoV as the alloy material of the pick body, and its heat treatment process parameters are: A 1 at 700°C, A 3 is 835°C and Ms is 356°C. The process steps are as follows: first place the pick on the tooling, make the intermediate frequency induction heating equipment surround the carbide head (ZD15 cemented carbide for geological and mining tools) and the end face of the pick handle to be welded, adjust the intermediate frequency induction between it and the welder The gap between the parts to 20mm, adjust the frequency of the intermediate frequency sensor to 7kHz, and keep it for 30s after reaching the temperature. The initial temperature of the top is controlled to be 1280°C, the amount of upsetting is 3 mm, and the welding upsetting is completed within 8 seconds after the heating stops. Then carry out overall induction heating and quenching on the pick, keep the heating frequency unchanged, keep it for 23s after reaching the temperature, spray liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com