Cable material for new energy vehicles and preparation method of material

A technology for new energy vehicles and cables, applied in circuits, electrical components, plastic/resin/wax insulators, etc., can solve problems such as unsatisfactory heat resistance performance, and achieve the effect of improving heat resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

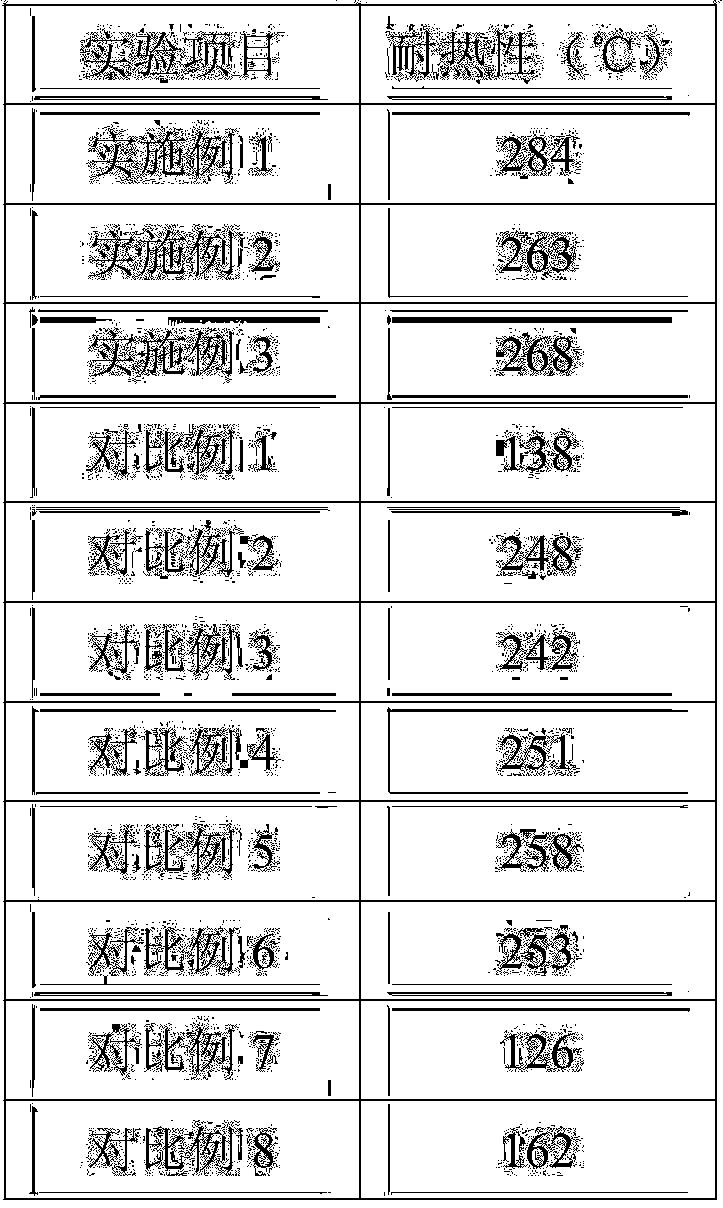

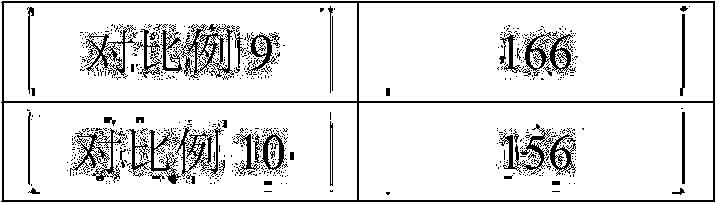

Examples

preparation example Construction

[0028] The preparation method of described new energy automobile cable material, comprises the following steps:

[0029] S1. Mix polyvinyl chloride resin, styrene-butadiene rubber and ammonium polyphosphate evenly, heat up to 120-130°C, keep warm for 10-30min, then stir at 1500-2500r / min for 10-30min, cool to room temperature to obtain the base material, Then add silane coupling agent A187 and tetrabromobisphenol A to the base material, stir magnetically under the protection of nitrogen, the speed of magnetic stirring is 450-650r / min, and then react at 130-150°C for 3-5h to obtain the modified group material;

[0030] S2. Mix SEBS rubber resin and PVC resin evenly, heat up to 110-130°C, keep warm for 20-40min, then add aluminum hydroxide, magnesium hydroxide, silicon hydrogen group, cellulose ether, carbon black N330, glass fiber, Sodium silicate, chlorinated paraffin, simethicone, expanded vermiculite, accelerator TMDT, zinc oxide, stearic acid, antioxidant RD are mixed even...

Embodiment 1

[0033] A cable material for new energy vehicles, comprising the following raw materials in parts by weight: 50 parts of polyvinyl chloride resin, 20 parts of SEBS rubber resin, 6 parts of styrene-butadiene rubber, 25 parts of PVC resin, 6 parts of ammonium polyphosphate, hydrogen 6 parts of aluminum oxide, 6 parts of magnesium hydroxide, 3 parts of silicon hydrogen group, 7 parts of cellulose ether, 6 parts of carbon black N3306, 7.5 parts of glass fiber, 6 parts of sodium silicate, 7 parts of chlorinated paraffin, simethicone 2 parts, 8 parts of expanded vermiculite, 20 parts of modified heat-resistant agent, 3.5 parts of vinyltriethoxysilane, 6 parts of accelerator TMDT, 6 parts of zinc oxide, 4.5 parts of stearic acid, 4 parts of anti-aging agent RD, Silane coupling agent A1876 parts, tetrabromobisphenol A 6 parts.

[0034] The modified heat-resistant agent is prepared according to the following process: 20 parts of polymethyl methacrylate, 12 parts of polyvinylidene fluori...

Embodiment 2

[0040] A cable material for new energy vehicles, comprising the following raw materials in parts by weight: 40 parts of polyvinyl chloride resin, 30 parts of SEBS rubber resin, 4 parts of styrene-butadiene rubber, 30 parts of PVC resin, 4 parts of ammonium polyphosphate, hydrogen 9 parts of alumina, 5 parts of magnesium hydroxide, 5 parts of silicon hydrogen, 4 parts of cellulose ether, 9 parts of carbon black N330, 6 parts of glass fiber, 8 parts of sodium silicate, 5 parts of chlorinated paraffin, simethicone 3 parts, 6 parts of expanded vermiculite, 25 parts of modified heat-resistant agent, 2 parts of vinyltriethoxysilane, 9 parts of accelerator TMDT, 4 parts of zinc oxide, 6 parts of stearic acid, 2 parts of anti-aging agent RD, Silane coupling agent A1878 parts, tetrabromobisphenol A 3 parts.

[0041] The modified heat-resistant agent is prepared according to the following process: 15 parts of polymethyl methacrylate, 16 parts of polyvinylidene fluoride and 4 parts of be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com