Ag/agf reference electrode suitable for fluoride molten salt and preparation method thereof

A reference electrode, fluoride technology, applied in electrochemical variables of materials, material analysis by electromagnetic means, instruments, etc., can solve the problems of short service life, easy cracking service life of graphite, complicated preparation process, etc., and achieve service life. Long, inexpensive and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Anodic Dissolution of Ag in Molten Salt and Preparation of AgF: Ag / Ag +The potential stability and reproducibility of the electrode pair are good, and the reversibility is good. It is very suitable as a reference electrode pair. In aqueous solution and chloride molten salt, the wide application of Ag / AgCl reference electrode proves that Ag / Ag + The excellent characteristics of the electric pair; take a reference tube with a polished film structure, fill it with silver wire, internal reference salt, and seal the sealing plug in turn. The anode and cathode of the regulated power supply are connected to the silver wire and tungsten wire respectively, and the constant current is 0.01A. Anodic Dissolution of Silver Filaments Produces Ag in Fluoride Internal Reference Salt + : Ag-e - =Ag + .

[0038] The present invention adopts the commercially available corundum tube as the diaphragm material; the present invention grinds the sealing end of the corundum tube into a film ...

Embodiment 1

[0041] In LiF-KF molten salt, use corundum tube, silver wire, and sealing plug to prepare the above reference electrode, including the following steps:

[0042] (1) The treatment of the corundum tube: take a corundum tube with a length of 30cm, an outer diameter of 8cm, and a wall thickness of 1cm, and polish the 0.2cm of the sealed end of the corundum tube into a film with a thickness of about 0.05mm.

[0043] (2) The processing of the silver wire: intercept 35cm silver wire (purity 99.99%, diameter 1mm), polish to light without scratches with sandpaper, then wash 5min successively with the ultrasonic wave that is equipped with alcohol, distilled water; Then silver wire One end is wound into a spring-like spiral (length 2cm), inserted into a corundum tube, dried in a vacuum oven at a constant temperature of 573K for 24 hours, and set aside;

[0044] (3) Weighing of the described reference salt: Weigh 1.3gLiF, 2.8gKF is ground and mixed evenly with a mortar, puts into a corund...

Embodiment 2

[0048] In LiF-KF molten salt, use silver wire, corundum tube, and sealing plug to prepare the above reference electrode, including the following steps:

[0049] (1) the processing of the corundum tube;

[0050] (2) the processing of the silver wire;

[0051] (3) taking by weighing of described reference salt;

[0052] (4) Anodic dissolution of silver wire and preparation of Ag / AgF reference electrode: constant current 0.01A anodic dissolution for 90min.

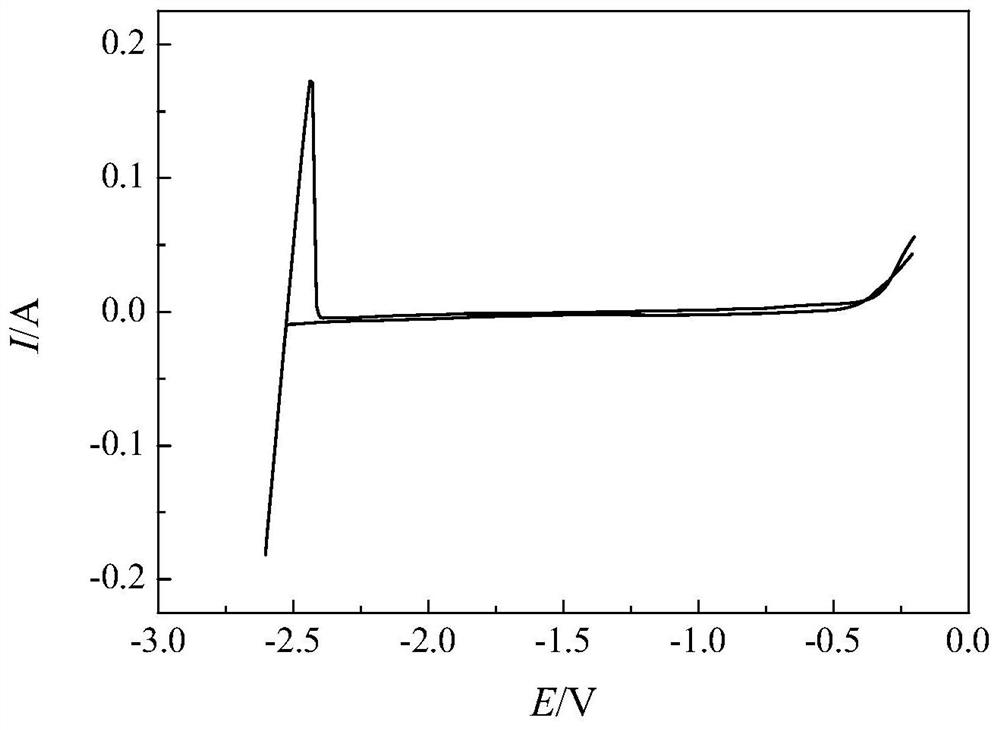

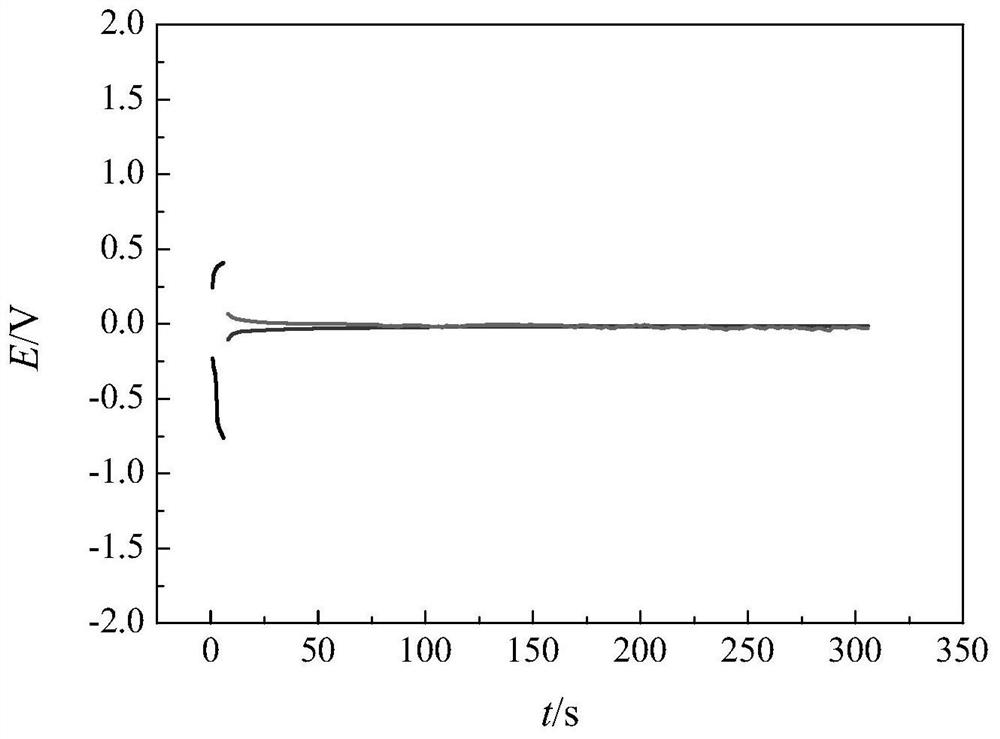

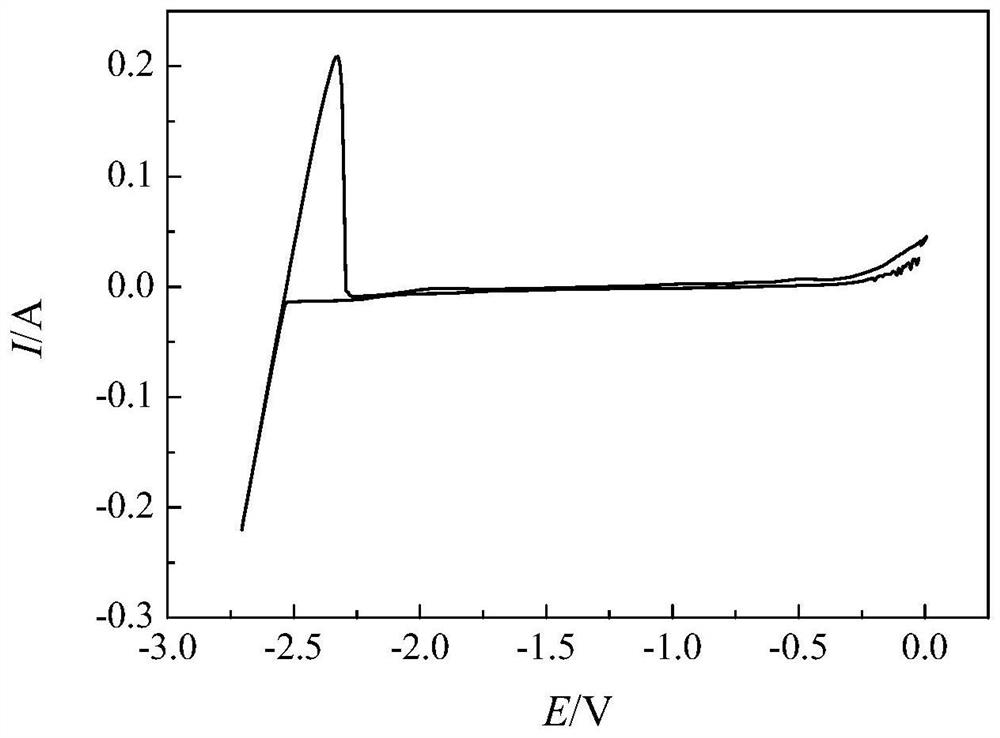

[0053] Putting the Ag / AgF reference electrode of implementation example 2 into the outer molten salt for 30min, the potential of the reference electrode is basically stable, and the cyclic voltammetry curve obtained is as follows image 3 As shown, the residual current is about 3mA, and the potential window is greater than 2V, which can be used for the electrochemical measurement of fluoride molten salt. Within 100 hours of use, the potential deviation is about 8mV; compare it with another Ag / AgF Electrode Composition Prim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com