Method for preparing metal hetero atom doped two-dimensional SnS2 nanosheet array vertically grown on carbon cloth as sodium ion battery anode material

A nanosheet array, sodium-ion battery technology, applied in secondary batteries, battery electrodes, chemical instruments and methods, etc., can solve the problems of poor conductivity, large volume change, easy particle agglomeration capacity attenuation, etc., to achieve strong binding force, The effect of simple synthesis steps and easy operation of synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

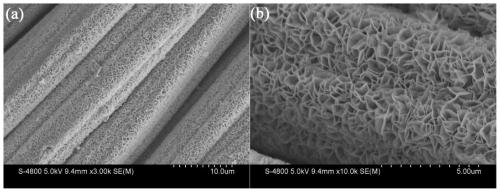

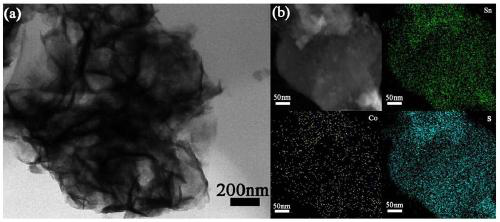

[0014] (1) Soak the purchased carbon cloth in 30% hydrogen peroxide solution at 40°C for 24 hours, then wash it with acetone, distilled water and absolute ethanol, and dry it for later use.

[0015] (2) Dissolve 0.3506g of tin tetrachloride pentahydrate, 0.1503g of thioacetamide and 23.79mg of cobalt chloride hexahydrate in 10ml of isopropanol, and stir for 30min to obtain a uniform and stable mixed solution.

[0016] (3) Transfer the mixed solution obtained in step (2) to a 15ml reaction kettle, slowly put the carbon cloth in (1) into the reaction kettle along the wall, and put the hydrothermal kettle into a 160°C Keep in the oven for 24h, and cool down to room temperature naturally.

[0017] (4) After taking out the carbon cloth in step (3), carefully wash it several times with distilled water and ethanol to remove excess salt, and then vacuum dry the carbon cloth at 80 °C for 12 h to obtain metal Co-doped SnS 2 / carbon cloth composite material.

Embodiment 2

[0019] (1) Soak the purchased carbon cloth in 30% hydrogen peroxide solution at 40°C for 24 hours, then wash it with acetone, distilled water and absolute ethanol, and dry it for later use.

[0020] (2) Dissolve 0.3506g of tin tetrachloride pentahydrate, 0.1503g of thioacetamide and 29.11mg of cobalt nitrate hexahydrate in 10ml of isopropanol, and stir for 30min.

[0021] (3) Transfer the homogeneous mixed solution obtained in step (2) to a 15ml reaction kettle, slowly put the carbon cloth in (1) into the reaction kettle along the wall, and put the hydrothermal kettle at 160°C Keep in the oven for 24h, and cool down to room temperature naturally.

[0022] (4) After taking out the carbon cloth in step (3), carefully wash it several times with distilled water and ethanol to remove excess salt, and then vacuum dry the carbon cloth at 80 °C for 12 h to obtain metal Co-doped SnS 2 / carbon cloth composite material.

Embodiment 3

[0024] (1) Soak the purchased carbon cloth in 30% hydrogen peroxide solution at 40°C for 24 hours, then wash it with acetone, distilled water and absolute ethanol, and dry it for later use.

[0025] (2) Dissolve 0.3506g of tin tetrachloride pentahydrate, 0.1503g of thioacetamide and 19.01mg of cobalt acetate tetrahydrate in 10ml of isopropanol, and stir for 30min.

[0026] (3) Transfer the homogeneous mixed solution obtained in step (2) to a 15ml reaction kettle, slowly put the carbon cloth in (1) into the reaction kettle along the wall, and put the hydrothermal kettle into 160 ℃ oven for 24 h, naturally cooled to room temperature.

[0027] (4) After taking out the carbon cloth in step (3), carefully wash it several times with distilled water and ethanol to remove excess salt, and then vacuum dry the carbon cloth at 80 °C for 12 h to obtain metal Co-doped SnS 2 / carbon cloth composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com