Colloidal pectin bismuth capsule and preparation process thereof

A preparation technology of colloidal bismuth pectin, applied in the direction of capsule delivery, medical preparations containing no active ingredients, medical preparations containing active ingredients, etc. Good, not conducive to labor protection and other issues, to achieve the effect of easy product quality control, easy swallowing, rapid disintegration and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

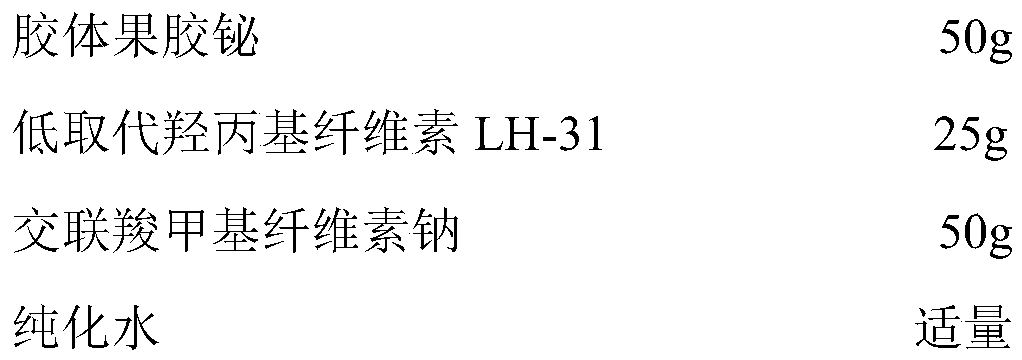

Embodiment 1

[0033]

[0034] Preparation Process:

[0035] (1) colloidal bismuth pectin and croscarmellose sodium are air-pulverized, mixed evenly according to the prescription amount, and set aside;

[0036] (2) Add low-substituted hydroxypropyl cellulose LH-31 into a centrifugal granulator, and slowly spray purified water into it to prepare a blank pellet core;

[0037] (3) Sprinkle the mixed powder prepared in (1) into the blank ball core prepared in (2) at a fixed rate, and spray purified water slowly at the same time. After the mixed powder is added, stop spraying purified water and continue spheronizing for 10 minutes ;

[0038] (4) Dry the pellets prepared in (3) in a fluidized bed, and fill them with capsules.

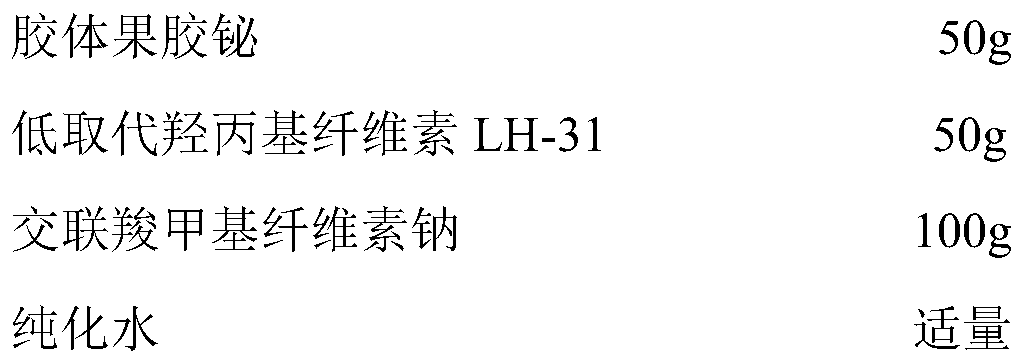

Embodiment 2

[0040]

[0041] Preparation Process:

[0042] (1) colloidal bismuth pectin and croscarmellose sodium are air-pulverized, mixed evenly according to the prescription amount, and set aside;

[0043] (2) Add low-substituted hydroxypropyl cellulose LH-31 into a centrifugal granulator, and slowly spray purified water into it to prepare a blank pellet core;

[0044] (3) Sprinkle the mixed powder prepared in (1) into the blank ball core prepared in (2) at a fixed rate, and spray purified water slowly at the same time. After the mixed powder is added, stop spraying purified water and continue spheronizing for 20 minutes ;

[0045] (4) Dry the pellets prepared in (3) in a fluidized bed, and fill them with capsules.

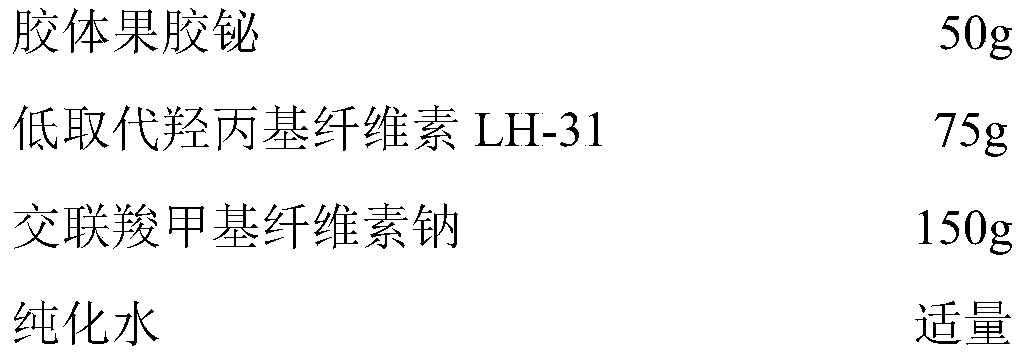

Embodiment 3

[0047]

[0048] Preparation Process:

[0049] (1) colloidal bismuth pectin and croscarmellose sodium are air-pulverized, mixed evenly according to the prescription amount, and set aside;

[0050] (2) Add low-substituted hydroxypropyl cellulose LH-31 into a centrifugal granulator, and slowly spray purified water into it to prepare a blank pellet core;

[0051] (3) Sprinkle the mixed powder prepared in (1) into the blank ball core prepared in (2) at a fixed rate, and spray purified water slowly at the same time. After the mixed powder is added, stop spraying purified water and continue spheronizing for 30 minutes ;

[0052] (4) Dry the pellets prepared in (3) in a fluidized bed, and fill them with capsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com