Foamed light soil and preparation method thereof

A technology of air-bubble lightweight soil and air bubbles, which is applied in the field of building materials, can solve the problems of low efficiency and high installation and construction costs, and achieve the effects of reducing self-shrinkage, improving construction performance, and optimizing hydration activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0044] Among the raw materials, ordinary Portland cement with P O 42.5 is used for cement, and the combination of fly ash and silica fume is used for industrial waste powder. The activity index of fly ash is 93%, the loss on ignition is 4.1%, and the sieve residue of 45μm square hole is 11%. , the activity index of silica fume is 110%, SiO 2 Mass content 93%, specific surface area 17000m 2 / kg. The waterproofing agent is selected from alkoxysilane waterproofing agent, and the surfactant is selected from sodium lauryl alcohol ether sulfate. Machine-made sand is used as filler, with a fineness modulus of 2.83, a crushing value of 7.4%, a methylene blue value (MB value) of 1.5, and a mass content of fine particles (particle size <0.075 μm) of 9%. The water is ordinary tap water.

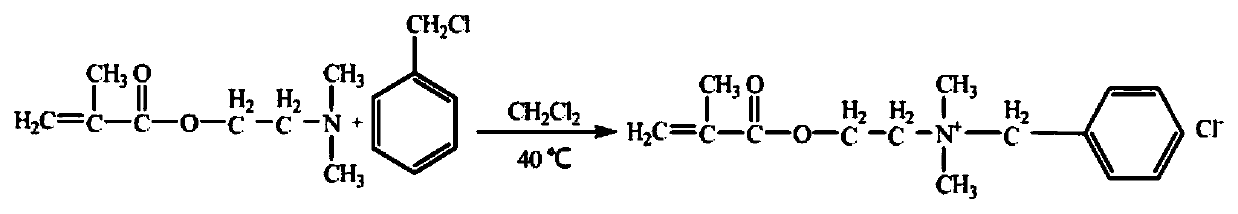

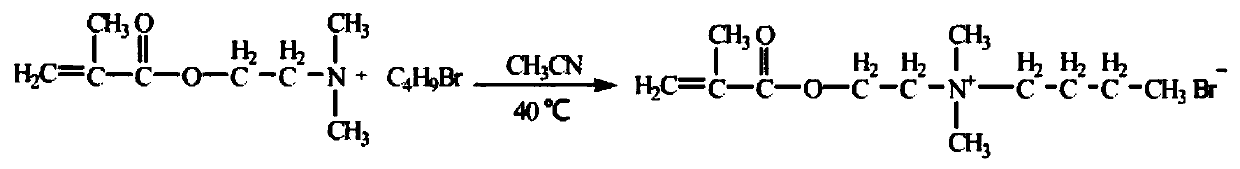

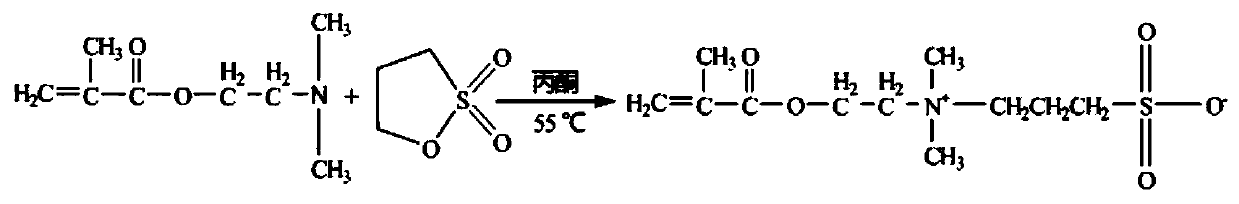

[0045] Among them, the following DM is dimethylaminoethyl methacrylate; the third functional body represents 3-(2-methacryloyloxyethyldimethylamino)propanesulfonate, and its chemical formula is HPE...

Embodiment 3~4

[0085] Among the raw materials, ordinary Portland cement with P O 42.5 is used for cement; blast furnace slag powder is used for industrial waste powder, and its specific surface area is 500m 2 / kg, the activity index is 97%; emulsified paraffin wax is selected as the waterproofing agent, vegetable protein foaming agent is selected as the surfactant; high-titanium heavy slag sand is used as the filler, the fineness modulus is 3.04, the crushing value is 5.4%, methylene The blue value (MB value) is 1.5, the mass content of fine particles (particle diameter<0.075 μm) is 4.1%; the water is ordinary tap water.

[0086] Composite high-energy expansion agent preparation comprises the following steps in the embodiment:

[0087] 1) Crushing the magnesite with a jaw crusher, and selecting particles with a particle size of 40 to 80 mm from the crushed tailings;

[0088] 2) Put the selected tailings particles of 40-80mm in a vacuum drying oven at 130°C for 2.5 hours, and grind them afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com