A Method of Fabricating Spherical Concave Mirrors on Optical Waveguides Based on Laser Cold Processing

A spherical concave surface and optical waveguide technology, applied in metal processing equipment, laser welding equipment, welding equipment, etc., can solve the problems of increasing process difficulty and complexity, troublesome optical backplane interconnection technology, and low vertical coupling efficiency. Low, improve vertical coupling efficiency, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

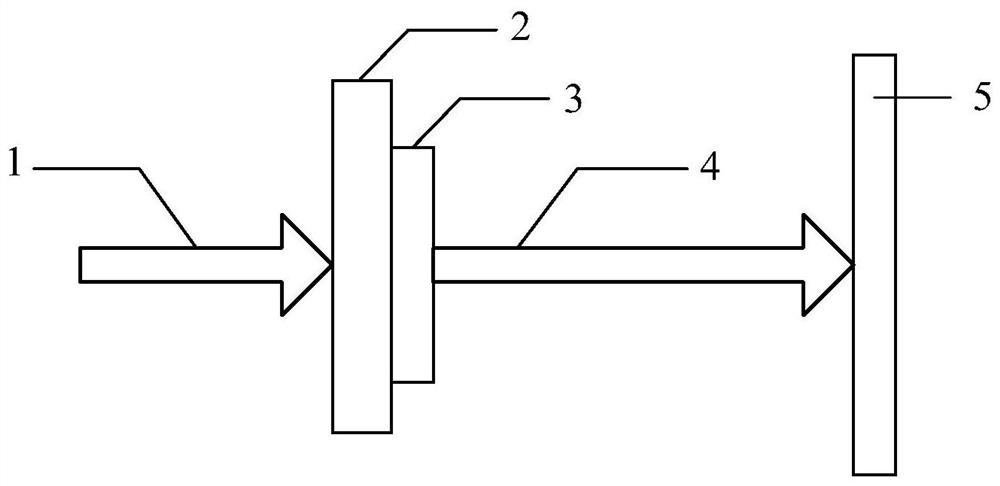

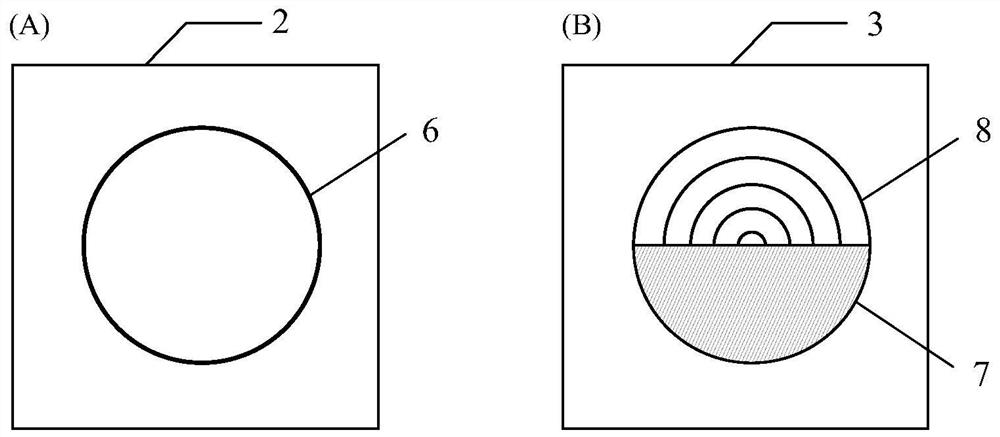

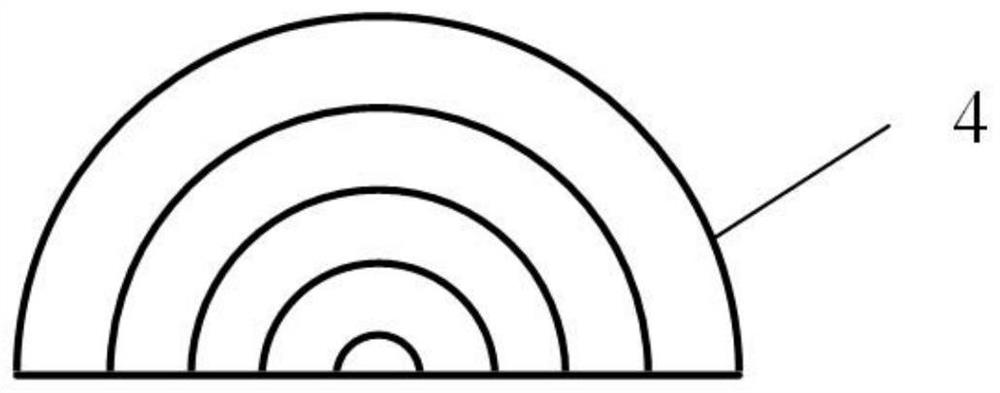

[0023] ginseng See Figure 1 to Figure 5 , this embodiment is based on a method of preparing a spherical concave mirror on an optical waveguide based on laser cold processing. The core part of the preparation equipment used is mainly a laser shaping device, which is mainly composed of a mask plate with a round hole that is opaque and can leak a circular beam of light, and a mask plate with different ion concentrations that is close to the hole of the mask plate. Doped special glass composition; the laser passes through the mask to generate a circular laser beam; the size of the doped area of this special glass is consistent with the size of the circular hole on the mask, and the semicircle of the doped area has high ion doping characteristics. The other semicircle has the distribution characteristic that the concentration of doping ions increases from the center to the radial edge; when the advancing laser passes through the laser shaping device, the light intensity of the...

Embodiment 2

[0025] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0026] The method for preparing a spherical concave mirror on an optical waveguide based on laser cold processing is characterized in that: select a suitable laser circle according to the size of the prepared spherical concave mirror, pass through a piece of opaque, with a circular hole, which can The circular laser beam is realized by leaking the mask plate of the circular beam, and the light intensity of each point of the circular laser beam is the same.

[0027]The method for preparing a spherical concave mirror on an optical waveguide based on laser cold processing is characterized in that: a piece of special glass doped with different ion concentrations is attached to the circular hole of the mask, and the shape of the doped region of this special glass is It is circular, and its size is consistent with the size of the circular hole on the mask. The ion doping has the ...

Embodiment 3

[0031] The preparation of spherical concave mirrors on the optical waveguide is mainly realized by using a laser shaping device. The laser beam passes through the laser shaping device. The laser shaping device is mainly composed of a mask plate 2 and ion-doped special glass 3. Finally, a semicircular laser beam 4 with a certain regular distribution of laser light intensity can be generated. This semicircular laser beam directly etches the optical waveguide 5 to form a strictly regular spherical concave surface, and the spherical concave surface is coated with a metal film or a dielectric high reflection film. , forming a spherical concave mirror.

[0032] see figure 2 , the material of the mask plate is opaque, with a round hole 6, the radius of the round hole is equal to the radius of the prepared spherical concave surface, and the laser beam passes through the round hole to form a circular laser beam with uniform light intensity; it is close to the mask Behind the mask is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com