Graphite felt-supported porous carbon-carbon cathode material as well as preparation method and application thereof

A cathode material, porous carbon technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as poor yield, limit electrode application, etc. Longer life and increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

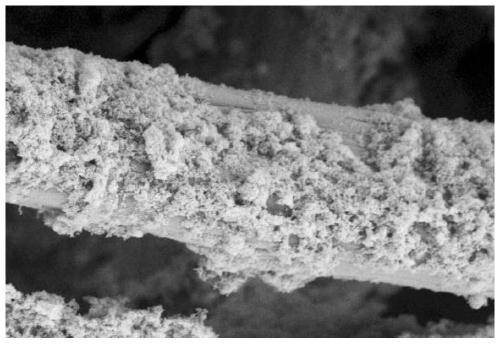

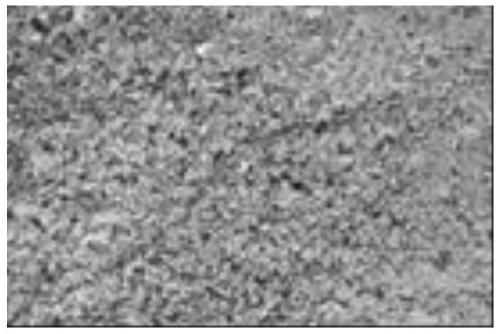

[0032] A kind of preparation method of graphite felt supported porous carbon cathode carbonaceous material in the electric Fenton system of the present invention, comprises the following steps,

[0033] Step 1, with 100~150ml ultrapure water or deionized water as solvent, Zn(NO 3 ) 2 ·6H 2 O and 2-methylimidazole are added, at this time Zn(NO 3 ) 2 ·6H 2 The concentration ratio of O and 2-methylimidazole is 74.4g / L:(114.03g / L~159.64g / L). After the compounding reaction is complete by 200~500rpm magnetic stirring for 12~24h, use a high-speed centrifuge at 8000~ Use methanol as a cleaning agent at 10,000rpm to completely remove 2-methylimidazole residues, centrifuge for 8-20 minutes to obtain the precursor of porous carbon; dry the precursor of porous carbon in a vacuum drying oven at 45-65°C for 5- 12h; put the dried precursor into the quartz boat, and pass an inert gas into the high-temperature tube furnace, such as N 2 After calcination and carbonization at 908-1100°C fo...

Embodiment 1

[0037] A method for preparing porous carbon-loaded graphite felt cathode carbonaceous material in an electric Fenton system of the present invention comprises the following steps,

[0038] Step 1, with 100ml ultrapure water as solvent, Zn(NO 3 ) 2 ·6H 2 O and 2-methylimidazole are added, at this time Zn(NO 3 ) 2 ·6H 2The concentration of O is 74.4g / L, and the concentration of 2-methylimidazole is 159.64g / L. After 24h of magnetic stirring at 250rpm, a high-speed centrifuge is used to centrifuge at 8000rpm using methanol as a cleaning agent for 20min to obtain the precursor of porous carbon. , dried in a vacuum oven at 50 °C for 5 h, put the obtained precursor into a quartz boat, and pass N into a high-temperature tube furnace 2 After calcination and carbonization at 1000°C for 5 hours, black powder porous carbon was obtained;

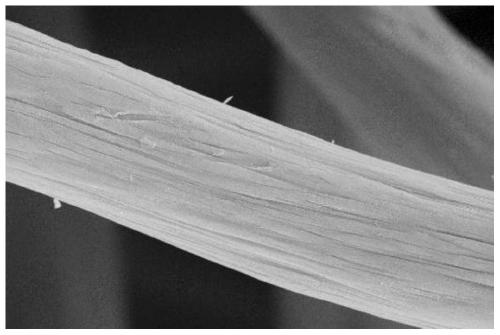

[0039] Step 2: Cut the commercialized graphite felt into 2cm×2cm size, add acetone and ultrasonically clean it for 30 minutes to remove oil, then ...

Embodiment 2

[0045] A method for preparing porous carbon-loaded graphite felt cathode carbonaceous material in an electric Fenton system of the present invention comprises the following steps,

[0046] Step 1, with 150ml ultrapure water as solvent, Zn(NO 3 ) 2 ·6H 2 O and 2-methylimidazole are added, at this time Zn(NO 3 ) 2 ·6H 2 The concentration of O is 74.4g / L, and the concentration of 2-methylimidazole is 114.03g / L. After 500rpm magnetic stirring for 12h, use a high-speed centrifuge to centrifuge at 10000rpm using methanol as a cleaning agent for 8min to obtain the precursor of porous carbon. , dried in a vacuum oven at 65 °C for 7 h, put the obtained precursor into a quartz boat, and pass N into a high-temperature tube furnace 2 After calcination and carbonization at 908°C for 7 hours, black powder porous carbon was obtained;

[0047] Step 2: Cut the commercialized graphite felt into 2cm×2cm size, add acetone and ultrasonically clean it for 30 minutes to remove oil, then rinse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com